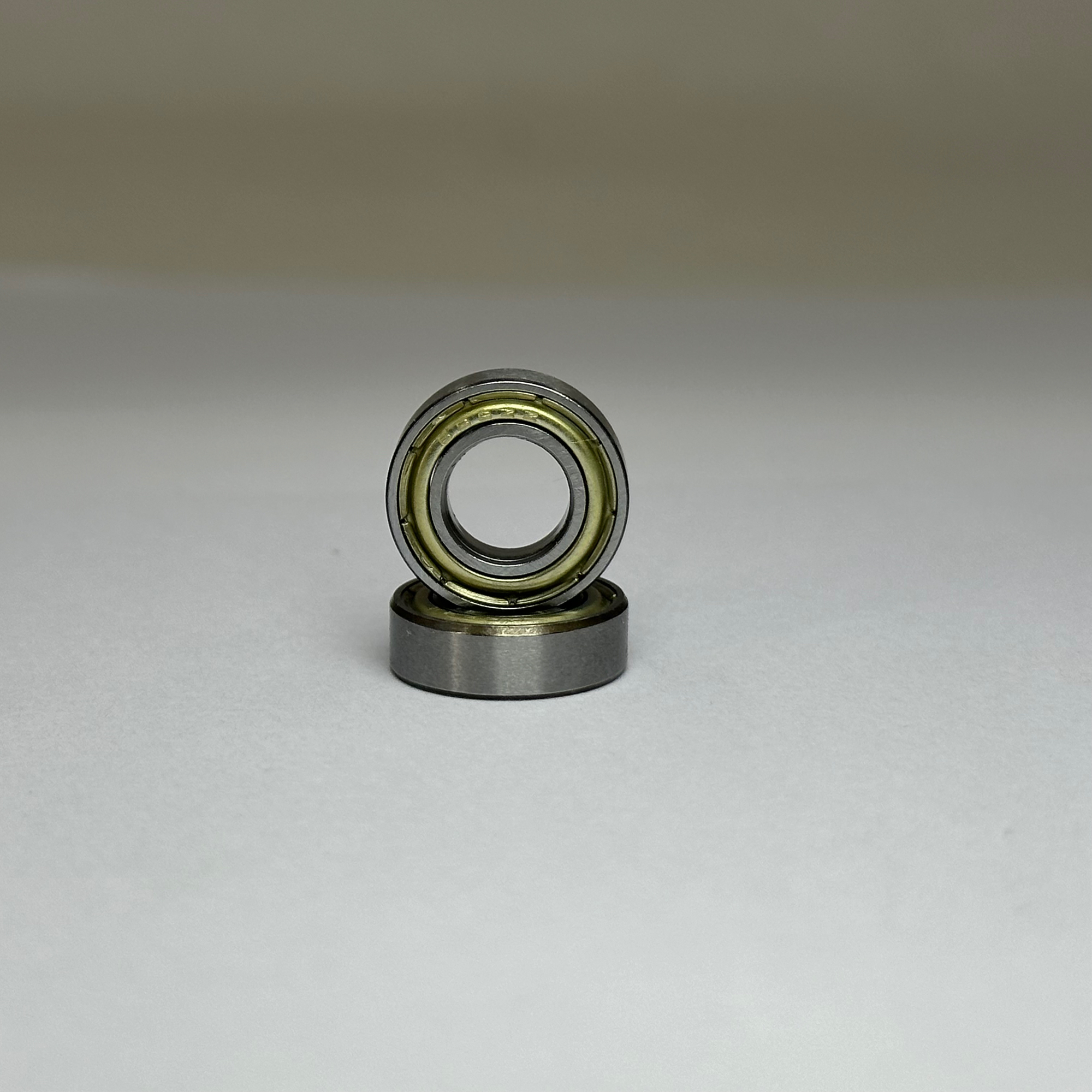

WG4005415308 Tapered Roller Bearing for HOWO Front Steering

Designed specifically for HOWO trucks, the WG4005415308 tapered roller bearing represents a precision-engineered solution for demanding front axle and steering system applications. With its advanced conical geometry and hardened steel construction, this original equipment manufacturer component ensures optimal load distribution across rolling elements and races. Manufactured to strict tolerance specifications, the WG4005415308 tapered bearing delivers reliable performance under extreme conditions including heavy payloads, uneven road surfaces, and temperature variations.

The innovative design of the WG4005415308 tapered roller bearing features precision-ground rollers positioned at optimal angles between cone and cup raceways. This configuration enables efficient management of both radial and thrust loads simultaneously – a critical requirement for front-wheel applications on heavy-duty trucks. By utilizing premium steel alloys and advanced heat treatment processes, this component achieves superior hardness while maintaining the necessary toughness to withstand impact loading conditions.

In steering systems, the performance of the WG4005415308 is particularly critical. During cornering maneuvers, these bearings transfer cornering forces through the spindle while absorbing vibrations from irregular road surfaces. The precise conical arrangement minimizes friction and heat generation, even when subjected to the combined side loads and suspension forces inherent to HOWO commercial vehicles operating in challenging environments.

Durability considerations extend to specialized cage designs incorporated in the WG4005415308. These retainers prevent roller-to-roller contact and ensure proper spacing between elements throughout the entire rotation cycle. Machined from high-strength materials ranging from pressed steel to engineered polymers, these cages demonstrate exceptional resilience against distortion even when exposed to extreme rotational forces.

Installation of the WG4005415308 tapered roller bearing requires precise preload adjustments to establish proper clearance parameters. This calibration determines the internal play within the bearing assembly, influencing both component longevity and vehicle handling characteristics. When correctly adjusted, this bearing delivers optimal stiffness for responsive steering feedback while providing sufficient flexibility to accommodate spindle deflections.

Maintenance protocols for the WG4005415308 follow recommended schedules based on accumulated mileage and operating conditions. Routine inspections focus on detecting wear patterns, cage integrity, and contamination levels within the assembly. Proper lubrication systems maintain oil film integrity between contacting surfaces, significantly extending service intervals while protecting against premature failure.

Performance testing of the WG4005415308 tapered roller bearing includes accelerated life simulations that replicate decades of operational stress within condensed timeframes. These evaluations validate the load-carrying capabilities, fatigue resistance, and thermal stability that make this component particularly suitable for vocational trucks operating in construction, mining, and long-haul transportation sectors.

The conical design principle of the WG4005415308 provides self-centering capabilities that compensate for minor alignment variations between mounted surfaces. This automatic alignment function reduces stress concentrations at critical points along bearing races, contributing to the overall longevity of the entire wheel-end assembly when properly maintained.

Sealing technology integrated with the WG4005415308 bearing assembly employs multi-layered barriers against contaminant ingress. These exclusion systems combine labyrinth paths with elastomeric contact elements to effectively block road debris, water, and dust particles while retaining lubricants within the critical wear zones. This protection proves essential when operating in off-road conditions with high contamination risk.

Temperature management represents another critical aspect of the WG4005415308 design. The specific dimensional relationships between components create optimal thermal expansion characteristics that maintain functional clearances throughout operating temperature ranges. Careful material selection ensures dimensional stability across the temperature spectrum encountered in severe service applications.

Standard replacement protocols recommend changing WG4005415308 bearings in complete sets rather than individual units. This practice prevents mismatched wear patterns and ensures uniform load distribution across both sides of the axle assembly. Timely replacement of these components prevents collateral damage to mating surfaces on wheel hubs and spindle assemblies.

The economic advantages of installing genuine WG4005415308 tapered roller bearings extend beyond initial purchase considerations. By minimizing unplanned downtime and preventing costly secondary component failures, these precision components offer compelling lifecycle cost benefits. Their predictable performance characteristics also simplify maintenance planning for commercial fleets with comprehensive preventative maintenance programs.

Advanced manufacturing techniques produce the WG4005415308 with exceptionally smooth raceway surfaces. These mirror-finish contact zones significantly reduce friction coefficients while providing ideal surfaces for hydrodynamic lubrication films to develop during operation. Such precision surface finishes are achieved through multi-stage grinding and superfinishing operations that leave minimal asperities.

Material science innovations incorporated in the WG4005415308 include specialized steel formulations optimized for fatigue resistance. Through controlled cooling processes and alloy development, modern bearing steels achieve microstructures that significantly outperform conventional materials. The resulting improvements in durability directly translate to extended service intervals under demanding operating conditions.

Vibration analysis techniques applied to the WG4005415308 during final quality verification detect sub-micron imperfections that could generate noise or reduce component lifespan. This non-destructive testing methodology complements dimensional inspections to guarantee consistent performance characteristics across all supplied units, delivering peace of mind to maintenance professionals.

For HOWO operators and technicians, the WG4005415308 tapered roller bearing provides the foundation for responsive handling and dependable service across varied operating conditions. Proper selection and installation of this critical component significantly contribute to overall vehicle safety by ensuring precise wheel alignment and steering responsiveness. Maintaining correct bearing adjustment settings remains essential for preserving the designed steering geometry that keeps heavy commercial vehicles tracking true.

Failure patterns associated with the WG4005415308 are predominantly progressive in nature, providing diagnostic warning signs before catastrophic breakdown occurs. These include distinctive acoustic signatures that change with wear progression, detectable temperature increases indicating lubrication breakdown, and measurable free play indicating clearance issues. Timely recognition of these symptoms prevents secondary component damage.

Replacement procedures for the WG4005415308 incorporate specialized tooling developed to streamline installation while preventing component damage. Proper mounting techniques distribute force uniformly across bearing races, preventing denting and brinelling that could compromise service life. Controlled hydraulic tools ensure precise application of installation forces at optimal rates and directions.

Environmental protection considerations in the WG4005415308 design extend beyond physical sealing mechanisms. Lubricant selection factors include biodegradability and reduced toxicity characteristics without compromising protective qualities. Many modern lubricants compatible with this bearing incorporate additive packages that enhance both component protection and environmental safety.

Global sourcing networks ensure consistent availability of authentic WG4005415308 tapered roller bearings for international HOWO operators. Regional distribution centers maintain comprehensive inventories to support urgent replacement requirements. This logistical infrastructure significantly reduces delays that could otherwise impact commercial fleet uptime statistics.

Technical documentation accompanying the WG4005415308 provides detailed installation torque specifications, clearance adjustment procedures, and lubrication requirements. These manufacturer-approved guidelines form the foundation for maximizing component life while minimizing unexpected failures. Adherence to these procedures ensures consistent performance and avoids premature warranty concerns.

Computational modeling capabilities have revolutionized the development process for tapered roller bearings like the WG4005415308. Finite element analysis accurately simulates load distributions within the assembly under various operating scenarios. This predictive modeling minimizes prototyping requirements while optimizing designs for both performance and manufacturability.

Looking toward future innovations, ongoing research surrounding the WG4005415308 tapered roller bearing focuses on extending maintenance intervals through advanced materials and surface engineering. Emerging technologies include diamond-like carbon coatings that demonstrate extraordinary potential for further friction reduction and enhanced resistance to micropitting damage mechanisms.

The geometric perfection inherent in the WG4005415308 tapered design provides the fundamental basis for its continued dominance in demanding automotive applications. Mathematical relationships controlling cone angles and curvature profiles ensure optimized stress distribution through the entire load zone. This sophisticated geometry represents the culmination of decades of empirical research and practical refinement.

Lubrication delivery systems developed specifically for the WG4005415308 operating environment provide targeted application to critical interface zones. Efficient distribution circuits minimize unnecessary lubricant quantity requirements while ensuring adequate coverage at contact points where pressure and temperature extremes develop during service.

For international operators of HOWO vehicles, understanding regional considerations affecting the WG4005415308 can optimize maintenance planning. Climate-specific factors ranging from humidity levels to temperature extremes influence lubricant selection and maintenance intervals. Terrain challenges from mountainous routes to desert conditions similarly dictate appropriate inspection frequencies.

Commercial fleet managers specializing in HOWO trucks recognize the WG4005415308 as a critical service component requiring strategic inventory planning. Maintenance scheduling algorithms incorporate bearing replacement cycles into comprehensive preventive maintenance programs designed to maximize vehicle uptime and minimize operating costs.

Educational resources developed around the WG4005415308 assist maintenance technicians in proper installation techniques and failure diagnosis. Training simulators recreate common failure scenarios while interactive documentation demonstrates correct adjustment procedures. These learning materials significantly reduce installation errors that could compromise bearing performance.

Industry standards governing the manufacturing specifications of the WG4005415308 ensure universal compatibility and safety compliance. Various organizations establish dimensional and performance benchmarks that leading manufacturers exceed through continuous development initiatives. These established protocols deliver confidence to engineering teams specifying components for critical applications.

Performance verification procedures applied to the WG4005415308 after installation include functional testing protocols that confirm proper operation. Run-in periods under controlled conditions establish initial lubrication distribution and seating patterns. Subsequent evaluation confirms temperature profiles within expected parameters, verifying correct preload settings.

The continued evolution of the WG4005415308 tapered roller bearing reflects ongoing material science advancements and manufacturing refinements. Incremental improvements accumulate over product generations, extending service life while enhancing performance capabilities. These continuous improvements solidify this design solution as the preferred approach for demanding wheel-end applications.