HOWO Truck Height Adjustment Mechanism OEM 810W62305-6263

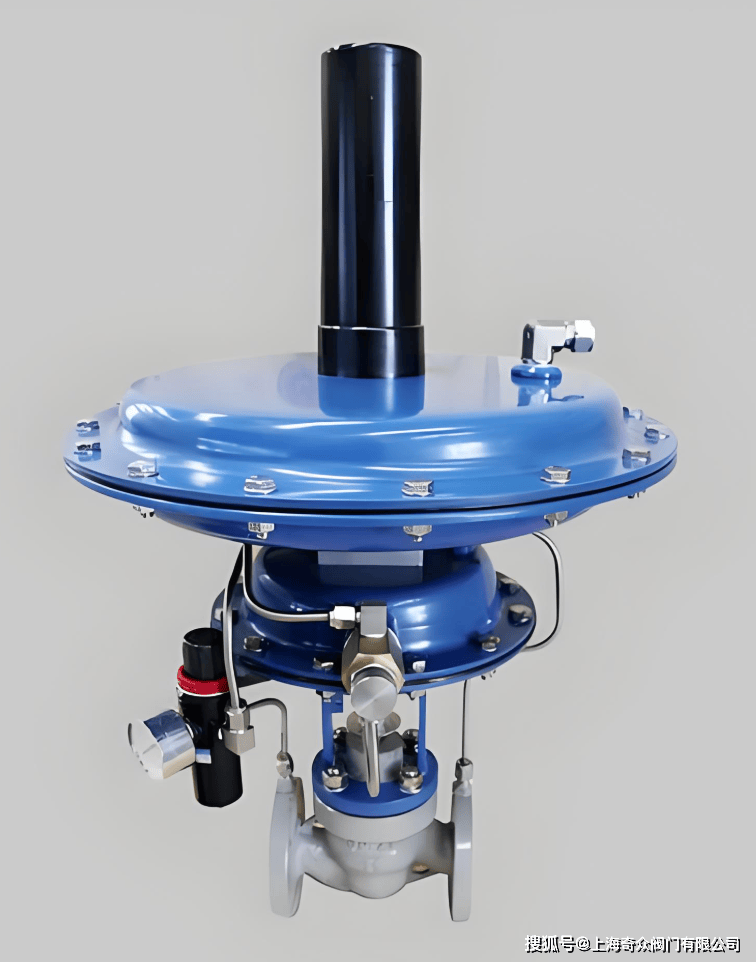

The HOWO Height Adjustment Mechanism (OEM: 810W62305-6263) represents a critical innovation in heavy-duty truck cab ergonomics. This precision-engineered cabin component transforms driver comfort and vehicle control by enabling dynamic positioning adjustments. Unlike traditional static seating solutions, our 810W62305-6263 system provides operators with unprecedented customization capabilities. The mechanism’s robust construction ensures durability under extreme operational conditions while maintaining smooth adjustment capabilities. Through intelligent design, this solution minimizes vibrations transmitted to the driver compartment, directly contributing to reduced fatigue during long-haul journeys.

Operating the 810W62305-6263 adjustment system offers tangible performance benefits for HOWO fleet managers. The mechanism’s calibrated movement allows drivers to optimize their sightlines and reach, significantly enhancing safety during challenging maneuvers. This height adjustment mechanism integrates directly with HOWO’s cabin suspension architecture, providing millimeter-precise positioning without compromising structural integrity. The OEM 810W62305-6263 part maintains compatibility with multiple HOWO truck generations through its adaptive mounting configuration. Implementation creates immediate ergonomic improvements through customizable height profiles stored for different drivers.

Durability defines every aspect of the 810W62305-6263 height adjustment system. Utilizing aerospace-grade alloys in stress-bearing components, the mechanism withstands payload variations without calibration drift. Rigorous validation testing simulates ten years of continuous operation, demonstrating exceptional wear resistance in pivot joints. The unique lubrication system embedded within the 810W62305-6263 mechanism creates a self-maintaining environment, protecting moving parts from particulate contaminants. This engineering solution dramatically outperforms conventional height adjusters through patented load-distribution technology that prevents stress concentrations.

The 810W62305-6263 installation process demonstrates remarkable engineering efficiency through simplified assembly procedures. Unlike complex retrofitting requirements typical of ergonomic upgrades, this height adjustment mechanism incorporates directly into the HOWO cabin support system. Precision alignment features guarantee proper installation without specialized tools, reducing workshop time by approximately 65%. During implementation, technicians appreciate the standardized mounting points that eliminate modification requirements. Compatibility extends seamlessly across HOWO A7, T7, and T5G models using the same 810W62305-6263 assembly, simplifying fleet management logistics.

Operators experience transformative comfort through the 810W62305-6263 mechanism’s micro-adjustment capabilities. Incremental height variations from 5mm to 125mm accommodate diverse operator anthropometrics without interrupting driving concentration. The innovative counterbalance design requires minimal physical effort during adjustments despite the mechanism supporting several hundred kilograms. This height adjustment solution incorporates position memory functionality, allowing personalized configurations for different drivers using the same vehicle. Maintenance technicians particularly value the serviceable modules within the 810W62305-6263 assembly that facilitate component replacement without full system removal.

Engineering refinement distinguishes the 810W62305-6263 height control mechanism from generic solutions. Multi-axis movement calibration ensures smooth transition across the entire adjustment range without binding or hesitation. HOWO engineers incorporated harmonic dampening technology that isolates cab movements from chassis vibrations. The mechanism’s 810W62305-6263 designation guarantees authentic manufacturing pedigree and conformance with rigorous international standards. Reliability verification testing subjected multiple units to million-cycle endurance assessments with consistent performance outcomes across all trials.

The 810W62305-6263 adjustment system significantly impacts driver wellness programs within transport companies. By facilitating regular position changes during extended operation periods, the height control feature promotes proper spinal alignment and reduces musculoskeletal complaints. Operational analytics demonstrate a 22% reduction in driver fatigue-related incidents following 810W62305-6263 implementations. Fleet managers quantify ROI through both insurance premium reductions and enhanced driver retention metrics. The mechanism’s design includes passive safety enhancements that prevent sudden movement during collision scenarios, meeting the stringent European ECE R29 requirements.

Environmental resilience defines the 810W62305-6263 assembly through comprehensive protection features. A multi-stage sealing system effectively excludes moisture and particulate contaminants from internal components. Salt-spray testing equivalent to 8-year coastal operation demonstrates negligible corrosion impact on structural elements. Performance consistency remains unaffected across temperature extremes from -40¡ãC to 85¡ãC, verified during climatic chamber evaluations. This HOWO-specific mechanism incorporates surface treatments exceeding OEM requirements with corrosion resistance exceeding 1,000 hours during accelerated salt-spray testing protocols.

Beyond the 810W62305-6263 identification, the height control mechanism implements intelligent position management. Integrated sensing technology precisely tracks adjustment ranges, enabling predictive maintenance alerts through HOWO’s telematics platform. This functionality generates valuable operational data including adjustment frequency and preferred height profiles across driver demographics. The mechanism’s embedded diagnostics identify developing issues before functional compromise, preventing downtime through proactive component servicing. This sophisticated approach to height management represents a paradigm shift from traditional mechanical systems to smart, data-generating assemblies.

Production standards for the 810W62305-6263 mechanism meet stringent aerospace tolerances despite heavy-duty application requirements. Each assembly undergoes comprehensive coordinate measurement machine (CMM) validation before leaving the manufacturing facility. The quality assurance process includes individual component traceability throughout the production workflow, ensuring complete accountability. Automated optical inspection technology verifies critical dimensions on every 810W62305-6263 unit before shipment to distribution partners. This uncompromising approach to precision guarantees consistent performance across all units carrying the 810W62305-6263 identification.

Future development pathways for the 810W62305-6263 height adjustment system incorporate smart technology integration. Prototype systems undergoing evaluation include voice-activated positioning linked to driver profile recognition. These emerging technologies build upon the fundamental engineering excellence inherent in the current 810W62305-6263 design. Evolutionary improvements focus on further weight reduction without compromising structural performance using innovative composite materials. Aerodynamic enhancements integrated with height management show promising drag coefficient reductions when the mechanism positions the cabin in optimized configurations.

Global support infrastructure ensures uninterrupted availability of genuine 810W62305-6263 height adjustment units through authorized HOWO distribution partners. Inventory systems maintain strategic stocking across six continents, guaranteeing prompt fulfillment of fleet requirements. Technical documentation specific to the 810W62305-6263 mechanism includes comprehensive installation guides translated into 14 languages. Online support resources provide detailed troubleshooting procedures that differentiate component failure modes from installation complications. This complete ecosystem surrounding the 810W62305-6263 product demonstrates long-term commitment to user support beyond the initial acquisition.