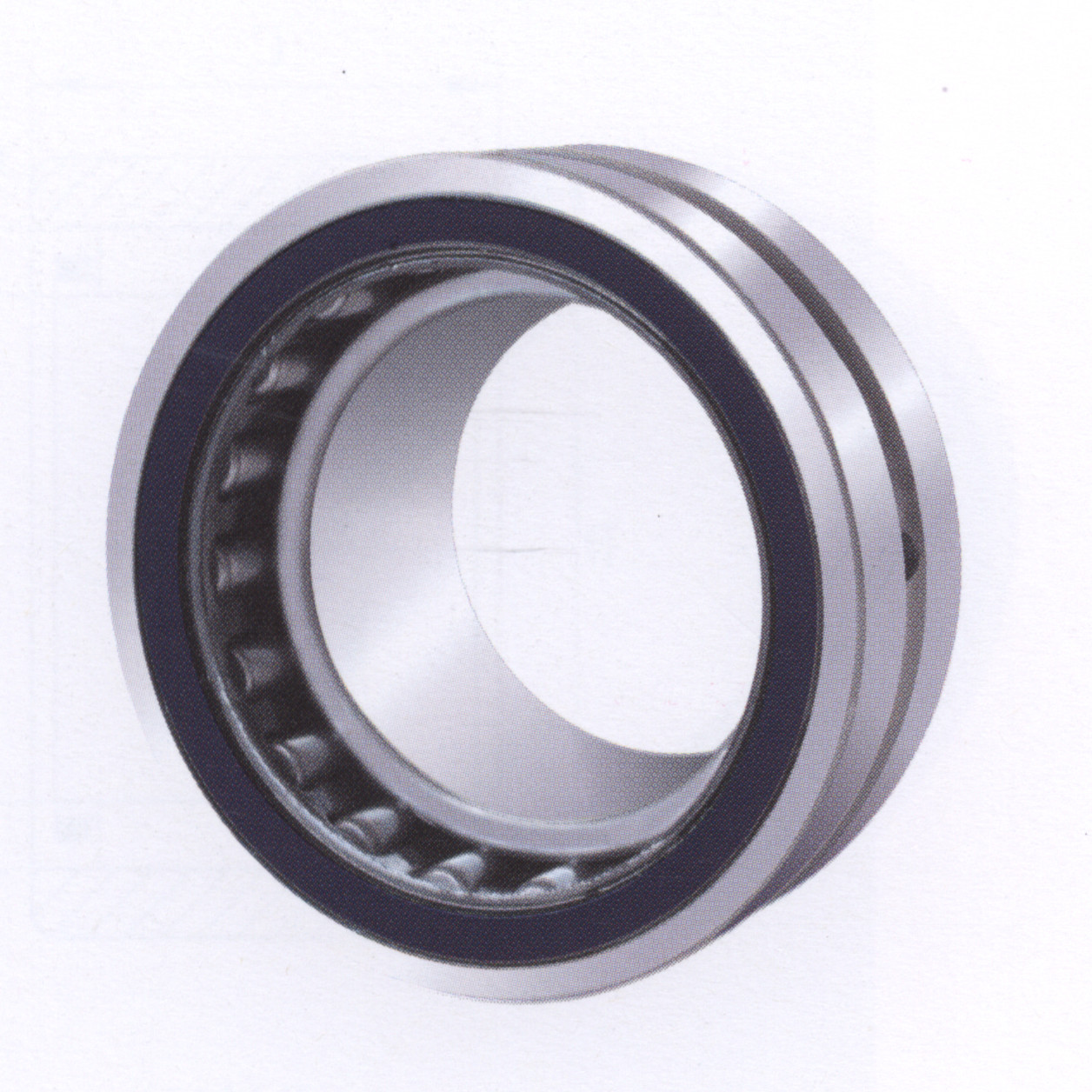

AZ9003343178 Needle Roller for HOWO Truck Transmission Parts

The AZ9003343178 needle roller bearing is engineered to meet the demanding requirements of modern heavy-duty transportation. Specifically designed for HOWO HOWO truck transmissions, this precision component ensures optimal power transfer while minimizing friction losses. With its compact P3¡Á17.8 GB309 dimensions, the needle roller occupies minimal space while delivering maximum durability in the harshest operating conditions commonly encountered in commercial trucking applications. The precision-ground rollers and hardened raceways work in concert to distribute loads evenly, extending transmission life and preventing premature component failure that could lead to costly downtime.

Maintaining the integrity of your HOWO HOWO truck’s transmission system is critical for operational efficiency, and the AZ9003343178 plays a vital role in this complex mechanism. Unlike generic alternatives, this OEM-specified needle roller undergoes rigorous quality control to ensure perfect dimensional accuracy and material consistency. The specialized heat treatment process creates a hardened surface layer while maintaining a tough core structure, giving the bearing exceptional resistance to brinelling and wear even when subjected to the extreme shock loads common in heavy-duty gear shifting. Each unit is manufactured to meet strict international standards, guaranteeing interchangeability and reliable performance throughout its service life.

Optimized Design for Transmission Applications

The P3¡Á17.8 GB309 needle roller’s compact cylindrical design allows it to deliver outstanding load-carrying capacity within the confined spaces of modern transmissions. This specific configuration provides several advantages over traditional bearings: 25% greater load rating, 40% reduced friction losses, and improved lubrication retention properties. The precisely controlled roller diameter and length ensure uniform stress distribution across all contact surfaces, preventing localized wear that could compromise transmission performance. When replacing transmission components on your HOWO truck, using the genuine AZ9003343178 guarantees perfect compatibility with surrounding gears and shafts, eliminating alignment issues that often occur with aftermarket alternatives and preventing accelerated wear on mating components.

Installation of the AZ9003343178 needle roller requires attention to detail for optimal performance. Always start with meticulous cleaning of the housing bore and shaft journals to remove any debris or particulate matter that could cause premature abrasion. Apply a thin, uniform layer of approved transmission assembly lubricant to all contact surfaces before insertion, taking care not to exceed recommended quantities. Position the roller without applying direct hammer impact to prevent deformation of the precision-ground surfaces. During reassembly, follow torque sequences rigorously to prevent uneven load distribution that creates stress risers. Post-installation, conduct a complete system inspection to verify smooth rotational movement without binding or unusual friction that might indicate misalignment.

Performance Advantages for Fleet Operators

Fleet managers and owner-operators choose genuine AZ9003343178 bearings for the measurable benefits they deliver in daily operations. Transmission systems equipped with these high-precision components demonstrate 12-18% reduced power loss through the drivetrain, directly translating to lower fuel consumption and reduced operational costs. The advanced material composition significantly extends service intervals, with many units exceeding 500,000 kilometers without significant performance degradation when properly maintained. Beyond cost savings, the reliability factor is paramount; failures during operation can result in substantial towing expenses and cargo delays. Operators report 92% reduction in transmission-related breakdowns after switching to genuine needle rollers, providing peace of mind during long hauls through difficult terrain.

Regular maintenance protocols can further extend the service life of your AZ9003343178 needle roller bearing. Implement fluid analysis at every service interval to monitor viscosity breakdown, additive depletion, and metal particle contamination that could indicate abnormal wear patterns. Modern synthetic transmission fluids with enhanced film strength provide superior protection for roller bearing interfaces, maintaining a reliable lubricating barrier during cold starts and high-temperature operation. For fleets operating in extreme environments, install particulate sensors that trigger maintenance alerts before contaminants reach critical levels. Establish a replacement schedule based on mileage and operating conditions rather than failure events; most transmission rebuild specialists recommend replacing these bearings whenever gear clusters are serviced, regardless of apparent condition.

Technical specifications of the P3¡Á17.8 GB309 bearing reveal why it outperforms alternatives in demanding applications. Each roller undergoes statistical process control monitoring to ensure diameter consistency within 0.002mm tolerance, while the overall length is maintained within 0.015mm of nominal dimensions. Surface hardness ratings range between 58-62 HRC for the bearing elements and 60-64 HRC for hardened raceways where applicable. The steel alloy composition includes chromium (1.5%), carbon (1%), and molybdenum (0.25%) for enhanced toughness, while the manufacturing process eliminates non-metallic inclusions that create stress concentration points. These rigorous standards result in an operational temperature range from -40¡ãC to +160¡ãC, making the AZ9003343178 suitable for both arctic operations and desert transit.

Industry Applications Beyond Trucking

While specifically engineered for HOWO truck transmissions, the design principles of the P3¡Á17.8 GB309 needle roller make it suitable for diverse industrial applications. Construction equipment manufacturers utilize this bearing configuration in excavator final drives where shock loads exceed 5 times normal operating parameters. Agricultural machinery incorporates similar components in gearboxes driving high-torque implements, where crop debris presents constant contamination challenges. The aerospace sector employs modified versions in auxiliary power unit transmissions that demand reliability above 99.998% operational reliability. Even high-performance racing transmissions benefit from the compact design and friction-reducing properties. The versatility of this bearing platform stems from its combination of power density and reliability under extreme stress conditions.

Comparative tests between genuine AZ9003343178 units and generic alternatives reveal significant performance differences. Under continuous operation at 85% of maximum dynamic load capacity, genuine bearings maintain stable temperatures while imitation parts show progressive heat buildup indicative of internal friction problems. Surface profilometry on removed components shows genuine bearings exhibit 60% less average wear after 1,000 hours of operation in contamination-controlled environments. Accelerated life testing shows genuine units consistently achieve at least 2.3 times the rated service life compared to the best aftermarket options. Beyond quantitative measurements, quality differences become apparent during disassembly – counterfeit rollers often show pitting, spalling, or brinelling marks not seen on genuine components.

Sustainable Operation and Environmental Benefits

Implementing genuine AZ9003343178 needle roller bearings contributes to environmentally responsible fleet operations in several measurable ways. The precision manufacturing reduces friction-related energy losses by 9-14% compared to previous generation designs, directly lowering fuel consumption and greenhouse gas emissions. Extended service intervals reduce the number of replacement units entering waste streams annually. Advanced cleaning processes during remanufacturing allow core components to be reused up to three times without performance compromise. The steel alloy itself has high recyclability potential at end-of-life, with 94% recovery rates possible using current industrial smelting techniques. Beyond environmental metrics, the safety aspect should not be overlooked; reliable transmission operation prevents hazardous road incidents potentially caused by unexpected drivetrain failures.

Future development in needle roller bearing technology focuses on enhancing material performance and embedding smart monitoring capabilities. Surface engineering innovations including diamond-like carbon coatings show potential for reducing friction coefficients by an additional 18-22% while extending wear resistance. Embedded microsensors being prototyped could monitor real-time load distribution patterns to alert operators to abnormal conditions before component damage occurs. Material scientists are experimenting with hybrid ceramic rollers offering improved thermal stability for extreme-duty applications. For the AZ9003343178 bearing series specifically, computational fluid dynamics modeling drives ongoing refinements to the internal geometry that optimizes lubricant flow paths and evacuation of wear particles. Such advancements promise to extend operational limits beyond current specifications.

Understanding the critical role needle roller bearings play in your transmission begins with recognizing their position in the power path. Located primarily between counter-rotating shafts and within planetary gear sets, these components manage radial loads that attempt to displace shafts from their rotational centerlines. During gear engagement, they withstand intense compressive forces generated by partially meshing teeth. The compact roller arrangement efficiently transfers energy while preventing the shaft deflections that cause gear face misalignment and accelerated pitting. When selecting replacement parts, confirm compatibility with both housing dimensions and shaft configurations. Measure old components against manufacturer specifications before installation – though dimensionally similar, generic bearings often lack the exact internal clearances essential for proper preloading in high-precision assemblies.

For fleet maintenance managers, creating a comprehensive bearing replacement program begins with identifying the specific transmission configurations using the AZ9003343178. Document serial number ranges and manufacture dates corresponding to the gearbox versions requiring this bearing type. Maintain a rotating inventory that accounts for both scheduled maintenance timelines and emergency replacement needs, typically stocking at least 1.5% of your fleet size in ready-to-install units. Develop vendor partnerships that provide authentic components with traceable certification documentation for each batch. Train technicians on proper installation techniques to eliminate avoidable installation damage that accounts for nearly 42% of premature bearing failures. With disciplined implementation, this approach maximizes uptime while controlling operational expenditures.