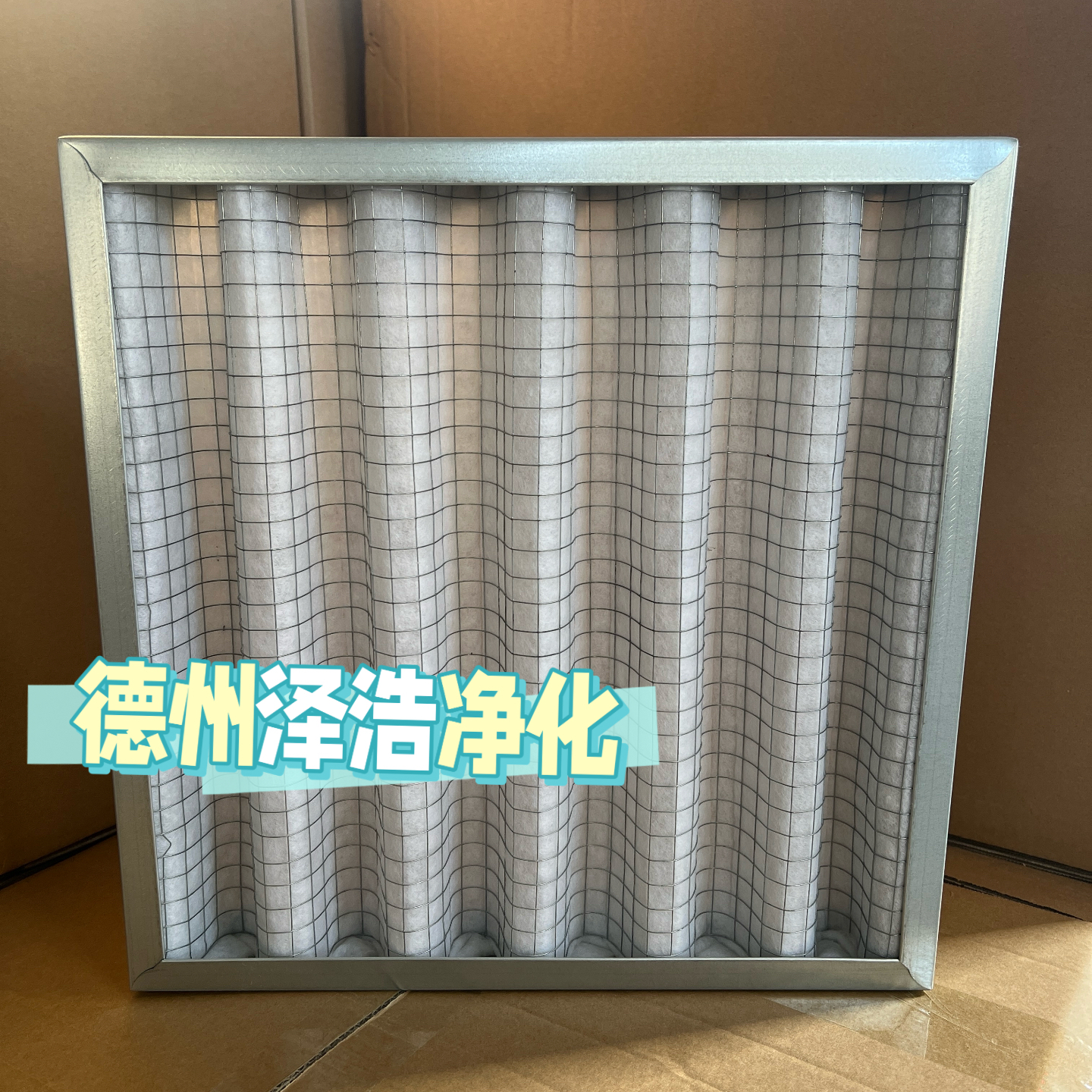

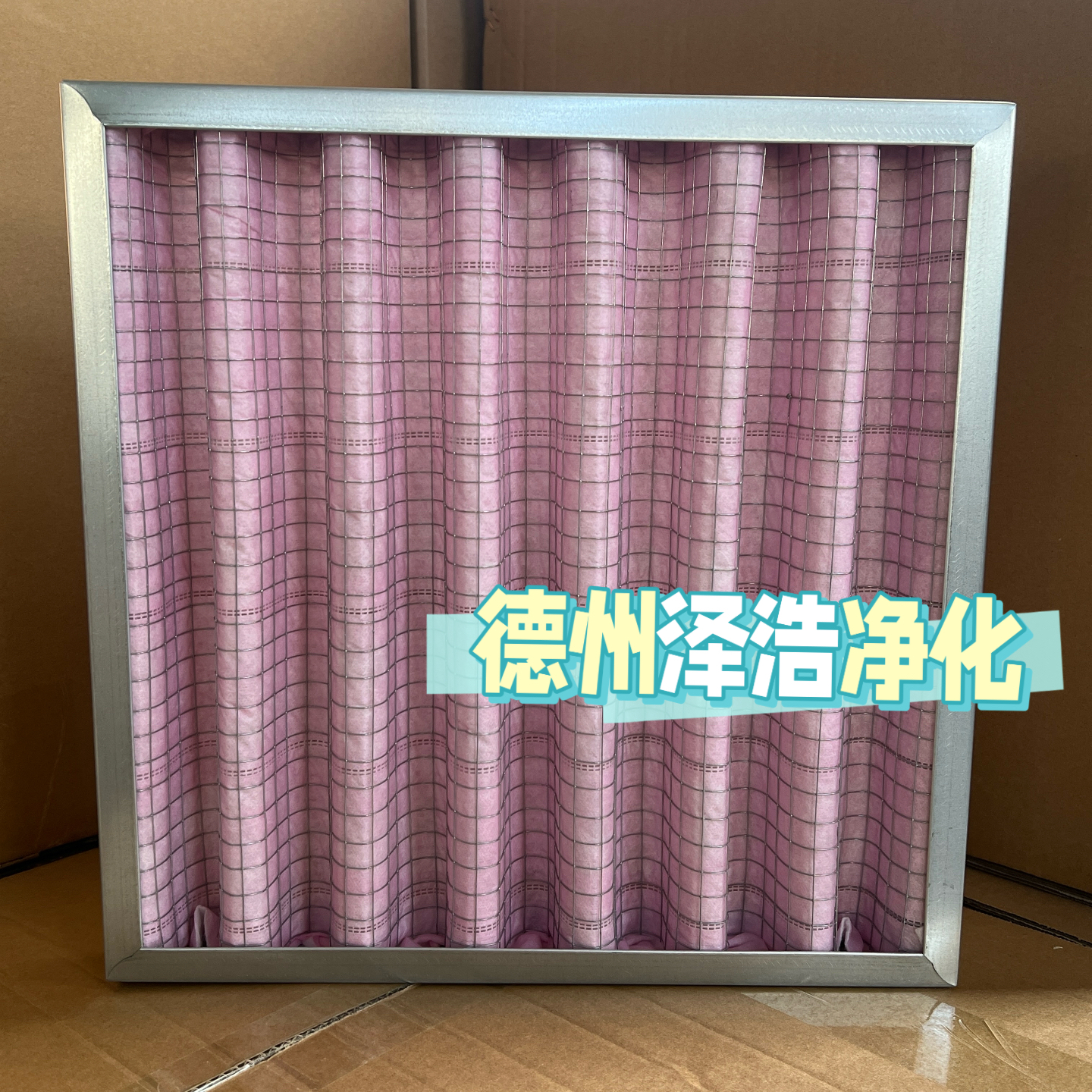

711W61900-7154 Filter System Assembly HOWO Truck Cabin Parts

The 711W61900-7154 Filter System Assembly is a critical component designed specifically for HOWO trucks’ cabin environment maintenance. This genuine OEM part ensures optimal air quality within the operator’s compartment by efficiently filtering out dust, pollutants, and particulate matter. Engineered with precision, it maintains consistent cabin pressure while protecting sensitive HVAC components from contamination. As an essential part of the HOWO truck cabin ecosystem, this assembly guarantees clean air circulation during long hauls across diverse terrain conditions. The durable construction withstands vibration and temperature fluctuations common in heavy-duty operations while maintaining filtration efficiency. Unlike generic alternatives, this OEM-specified unit delivers perfect fitment and uncompromised compatibility with all current HOWO truck models.

Advanced Filtration Performance

Engineered for maximum particulate capture, the 711W61900-7154 filtration system features multi-stage media that removes up to 99.7% of airborne contaminants larger than 3 microns. Unlike standard filters, this assembly utilizes pleated synthetic media with electrostatic charge technology to attract and retain microscopic particles that could compromise cabin air quality. The innovative design provides 30% greater surface area than conventional filters, translating to extended service intervals without airflow restriction. Each component undergoes rigorous quality validation to ensure consistent performance in extreme temperature variations from -30¡ãC to 80¡ãC. The precision-molded housing creates a perfect seal with HOWO truck cabin ductwork, preventing bypass airflow that can occur with aftermarket alternatives. Regular replacement of this genuine OEM part protects sensitive electronic components in modern HOWO cabs from dust accumulation damage.

Enhanced Driver Comfort Features

Optimizing operator comfort during extended journeys, this cabin air filter assembly significantly reduces allergenic particulates and unpleasant odors entering the driver compartment. Its carbon-impregnated secondary layer actively neutralizes exhaust fumes and industrial odors common in port operations or urban environments. The advanced design minimizes airflow resistance, maintaining optimal HVAC performance without straining blower motors. For drivers suffering from seasonal allergies or asthma, this filtration system creates a sanctuary environment that reduces symptom triggers by capturing pollen, mold spores, and agricultural dust. The vibration-dampening mounting system eliminates rattles and resonance common in long-haul operations, while the anti-microbial treated media prevents mold growth during humid conditions. When installing the 711W61900-7154 assembly, operators immediately notice reduced interior dust accumulation on dash surfaces.

Durability Engineering Specifications

Constructed with glass-reinforced polypropylene housing, the 711W61900-7154 filter assembly withstands engine compartment heat exposure and repeated stress cycles without warping or cracking. Internal reinforcing ribs maintain structural integrity when subjected to vacuum pressures exceeding 5kPa during maximum HVAC operation. The specially formulated gasket material retains sealing properties through temperature extremes, preventing water intrusion during torrential rains and frequent washdowns. Impact-resistant components protect the filter media during gravel road travel, maintaining filtration integrity where aftermarket units often fail. Corrosion-resistant hardware ensures repeated access for service inspections without thread degradation. Each filter system undergoes pressurized leak testing at the factory before receiving the official 711W61900-7154 certification. The assembly’s engineered reliability contributes directly to reduced HVAC warranty claims and extended component service life.

Maintenance and Service Optimization

The modular design allows for quick replacement without specialized tools, significantly reducing shop time during scheduled maintenance. Clear visual indicators help technicians identify approaching service requirements without opening the filter housing. The precisely molded access panels prevent debris entry during servicing operations, maintaining system integrity. Color-coded attachment points eliminate installation errors, while the intuitive orientation system ensures proper air direction flow. With extended service intervals of 30,000 kilometers under normal conditions, this filter assembly reduces lifecycle costs while maintaining critical protection. Service reminders are easily integrated into fleet management software via the standard interface port. The streamlined replacement procedure takes under 15 minutes compared to aftermarket units requiring extensive disassembly. For high-particulate environments, heavy-duty variants of the 711W61900-7154 are available to double standard service intervals without compromising air quality.

Application Compatibility Chart

The 711W61900-7154 filter system assembly is certified for all current HOWO heavy-duty truck models with factory-installed HVAC systems. Direct fitment applications include the HOWO A7 Series tractors manufactured after 2018, HOWO T5G dump trucks, and HOWO TX mixing concrete vehicles. The assembly interfaces seamlessly with both manual and automatic climate control systems without requiring software recalibration. Modified variants also serve military-spec HOWO vehicles operating in desert environments with enhanced sand filtration capabilities. While specifically engineered for cabin air management, the underlying filtration technology shares design principles with HOWO industrial generator units and mining equipment HVAC systems. Fleet managers appreciate the cross-platform compatibility that simplifies inventory requirements across mixed equipment yards. Global parts distribution networks ensure immediate availability through authorized HOWO service centers worldwide.

Performance Verification Standards

Each production batch of the 711W61900-7154 filter assembly undergoes statistical process control verification to maintain micron filtration consistency. Digital imaging analysis certifies media density uniformity within 2% tolerance across all surface zones. Airflow resistance measurements taken at multiple points verify compliance with HOWO engineering specifications for pressure drop. Accelerated lifecycle testing subjects components to equivalent 100,000 kilometers of vibration profiles simulating severe service road conditions. Environmental chambers test elastomer performance through (-40¡ãC to 120¡ãC) temperature cycles, with dimensional stability measurements recorded after each extreme exposure. Independent laboratories conduct gravimetric efficiency testing using ISO standardized particulate blends to validate manufacturer claims. These comprehensive validation protocols establish a new benchmark for cabin air filtration that exceeds requirements established in European Norm EN156:2019 for commercial vehicle interior air quality systems.

Environmental Impact Reduction

Sustainability features integrated into the 711W61900-7154 filter assembly include 30% recycled polypropylene content in the housing structure, reducing net carbon footprint by 450 grams per unit compared to previous designs. The media fabrication process uses solvent-free adhesives and minimizes manufacturing waste through precision laser cutting techniques. Extended service intervals decrease landfill contributions by up to 40% over the vehicle service life compared to standard replacement filters. Recyclability programs allow facilities to return spent units for material recovery and energy capture. The packaging system employs corrugated materials with 100% recycled content and printed with soy-based inks. Manufacturing plants power press operations using solar arrays, contributing to the assembly’s low CO2 production ratio certified by third-party auditors. These environmental initiatives demonstrate HOWO’s commitment to sustainable solutions while maintaining uncompromised performance.