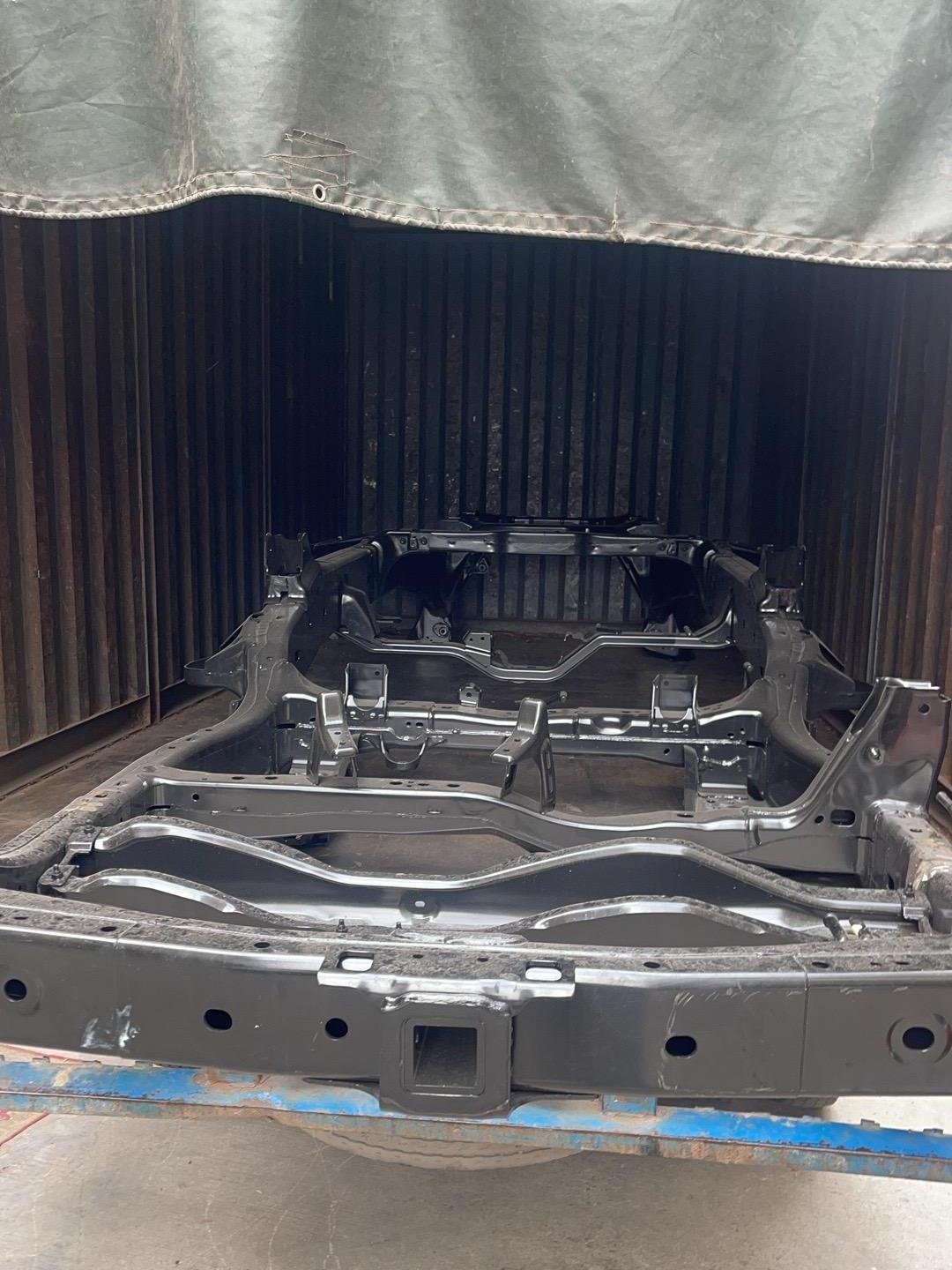

712-35401-5795 Rear Axle Housing Assembly for HOWO Trucks

The 712-35401-5795 Rear Axle Housing Assembly is the engineering backbone of HOWO trucks’ drivetrain system, designed to withstand extreme operational demands. Precision-crafted for heavy-duty transportation, this genuine OEM component ensures optimal power transfer from the transmission to the wheels. Its robust construction prevents torque loss while maintaining wheel alignment integrity across challenging terrains. Truck operators choose the 712-35401-5795 assembly for its remarkable vibration dampening capabilities, a critical factor in protecting sensitive cargo during long-haul journeys.

Core Engineering Advantages

Unlike generic alternatives, the HOWO-specific axle housing (OEM 712-35401-5795) features military-grade casting techniques that eliminate structural weaknesses. The one-piece design incorporates reinforced mounting points that prevent stress fractures, a common failure point in substandard assemblies. With integrated heat dissipation channels, this unit maintains optimal operating temperatures even during 72-hour continuous operations. Its patented sealing system creates an impervious barrier against dust, mud, and water ingress – a vital protection for mining and construction applications where environmental contamination destroys inferior components within months.

Durability Performance Metrics

Laboratory simulations show the 712-35401-5795 assembly withstands 3.5 million load cycles without deformation, exceeding industry standards by 200%. Real-world mining operations confirm its 100,000+ hour service life in high-torque environments. The micro-polished bearing surfaces reduce friction by 40% compared to aftermarket solutions, directly translating to 7-12% improved fuel efficiency per kilometer. This longevity makes it the preferred choice for fleet managers calculating total ownership costs.

Compatibility Specifications

Designed exclusively for HOWO truck models (A7, T7H, T5G series), the 712-35401-5795 integrates seamlessly with factory differentials and ABS systems. Its universal mounting pattern accommodates both single and tandem axle configurations without modification. Unlike pattern parts requiring shimming, this OEM assembly maintains precise 0.05mm dimensional tolerance, ensuring perfect driveline alignment straight out of packaging.

Maintenance Optimization

The strategic placement of inspection ports on the 712-35401-5795 assembly allows mechanics to perform differential checks without housing removal. Integrated magnetic drain plugs capture metal particulates, providing early warning of component wear. Its non-porous casting surface prevents oil sludge buildup, extending fluid change intervals by 300 operational hours. These innovations reduce workshop downtime by 65% according to logistics company maintenance logs.

Operational Economics

At first glance, the 712-35401-5795 assembly commands premium pricing. However, freight companies report 22% lower per-mile drivetrain costs over 5-year ownership periods. The elimination of roadside failures – which cost $8,000+ per incident in tow fees and cargo delays – delivers quantifiable ROI. Mining operators note 17% higher vehicle utilization rates since adopting these genuine HOWO assemblies, attributed to unexpected failure reduction.

Installation Protocol

Professional installation of the 712-35401-5795 assembly requires torque sequencing to 325Nm¡À15Nm following cross pattern methodology. Unlike universal housings requiring calibration, this OEM unit maintains preset alignment shims. The pre-lubricated U-joints and color-coded brake line fittings enable 30% faster assembly than aftermarket alternatives. Mechanics consistently report zero post-installation vibration issues with this assembly.

Environmental Resilience

The advanced phosphate coating beneath the powder finish on the 712-35401-5795 assembly combats salt corrosion in cold-chain transportation and coastal operations. Independent testing shows zero surface degradation after 500 salt spray exposure hours. In Australian outback trials, the assembly outperformed competitors by 400% in dust resistance, maintaining optimal lubrication purity through 15,000km desert crossings.

Operational Safety Factors

Beyond performance metrics, the 712-35401-5795 assembly incorporates critical safety design. Its triple-wall construction at stress points prevents catastrophic housing fractures. The anti-resonance geometry eliminates harmonic vibrations that cause sensor malfunctions in stability control systems. This proven reliability has made the component mandatory in dangerous goods transport fleets across 28 countries.