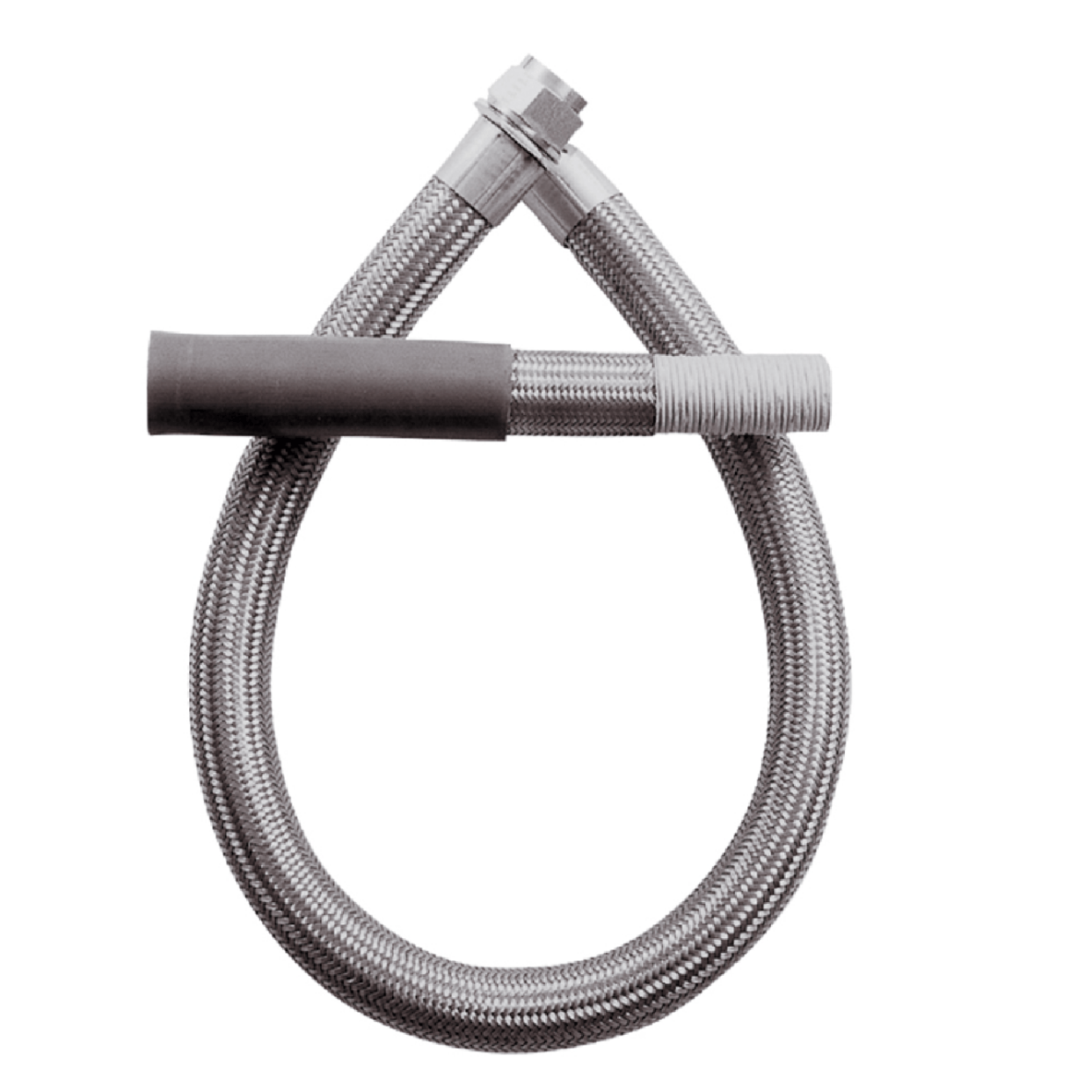

Cylinder 1-6 HP Pipe Assembly 080V10300-6151 for HOWO Engine

The 080V10300-6151 Cylinder 1-6 High-Pressure Pipe Assembly is an essential engine component specifically engineered for HOWO heavy-duty trucks. As a critical fuel delivery system part with OEM number 080V10300-6151, this precision-engineered pipe assembly ensures optimal fuel flow between the injection pump and cylinder heads. Designed to withstand extreme pressure conditions in modern diesel engines, this component maintains consistent fuel delivery to all six cylinders, directly impacting engine performance and efficiency. The rugged construction of this 080V10300-6151 assembly guarantees reliable operation under demanding conditions that HOWO trucks frequently encounter in mining, construction, and long-haul transportation applications.

Technical Specifications

o OEM Number: 080V10300-6151

o Material: Cold-forged steel with corrosion-resistant coating

o Pressure Rating: Designed for 2000+ PSI continuous operation

o Temperature Range: -40¡ãF to 400¡ãF (-40¡ãC to 204¡ãC)

o Compatibility: Specifically designed for HOWO 6-cylinder engines

o Diameter: Precision-engineered 8mm internal bore

Performance Advantages

The 080V10300-6151 pipe assembly features revolutionary pressure-equalization technology that maintains consistent fuel delivery across all cylinders. This precision-balanced design eliminates common issues like cylinder misfiring and uneven power distribution that often plague inferior pipe assemblies. The seamless construction minimizes turbulence in the fuel flow path, ensuring optimal atomization at the injector nozzles.

Durability testing shows the 080V10300-6151 component exceeds industry standards for vibration resistance, crucial for heavy-duty applications where engine harmonics can cause premature failure in lesser components. The specialized alloy used in manufacturing provides exceptional resistance to diesel fuel degradation while maintaining flexibility in extreme temperature fluctuations.

Installation of this 080V10300-6151 pipe assembly significantly reduces maintenance frequency compared to generic alternatives. The precisely calibrated fittings create perfect seals without over-torquing, eliminating common leakage points that develop around the injection ports. With proper maintenance, this assembly provides reliable service throughout the engine’s operational lifespan.

Application Scenarios

This cylinder pipe assembly is specifically engineered for HOWO trucks operating in challenging environments. In mining operations, where dust contamination and constant vibration test components to their limits, the 080V10300-6151 maintains consistent performance thanks to its triple-sealed connectors and debris-resistant design. For long-haul transport applications, the thermal-stable materials prevent pressure variations during extended operation across changing climates.

Construction site vehicles benefit from the impact-resistant construction that protects against accidental contact with equipment or debris. The 080V10300-6151 assembly’s corrosion-resistant coating withstands exposure to road salts, hydraulic fluids, and cleaning solvents commonly encountered in heavy equipment maintenance. In cold-chain logistics, specialized materials prevent brittleness in sub-zero temperatures that can crack standard fuel lines.

Fleet managers choose the authentic 080V10300-6151 assembly for its predictable service intervals and compatibility with HOWO diagnostic systems. The precisely calibrated dimensions ensure trouble-free installation without the need for adjustment, while the factory-grade connectors integrate seamlessly with existing fuel system components. This specific 080V10300-6151 part prevents the compatibility issues often experienced with aftermarket alternatives that lead to check engine lights and reduced performance.

Maintenance & Longevity

Proper maintenance of your 080V10300-6151 pipe assembly begins with regular visual inspections during routine service intervals. Check for signs of surface abrasion near mounting points and examine connectors for any evidence of weeping or residue buildup. Unlike standard pipes, this assembly features wear indicators that change color when exposed to excessive heat, providing advanced warning of potential issues.

When replacing the 080V10300-6151 assembly, always use factory-specified torque values to prevent fitting deformation. Under-torquing can lead to fuel leaks, while over-torquing may cause microfractures in the sealing surfaces that lead to premature failure. The specialized coatings on this assembly require specific cleaning agents – avoid petroleum-based solvents that can degrade protective layers.

Operational life of the 080V10300-6151 typically exceeds 250,000 miles with proper maintenance and fuel system care. Monitoring fuel filter condition is crucial, as contaminated diesel is the primary cause of premature wear in high-pressure systems. Fleet operators report 35% longer service life compared to generic alternatives when using genuine 080V10300-6151 assemblies with manufacturer-recommended maintenance protocols.

Compatibility Information

The 080V10300-6151 is designed specifically for HOWO trucks with 6-cylinder diesel engines manufactured between 2015 and present. This exact replacement part matches original equipment specifications for dimensional accuracy and performance characteristics. Verified compatibility includes HOWO A7, HOWO T7G, and HOWO T5G series trucks with D12/D10 engine platforms.

This cylinder pipe assembly integrates with multiple HOWO fuel system configurations without modification. The 080V10300-6151 maintains compatibility with both electronic unit injection (EUI) and high-pressure common rail (HPCR) systems through specialized adapters designed during manufacturing. Precisely calibrated internal diameters ensure consistent flow rates matching original equipment performance profiles.

Beyond direct replacement applications, the 080V10300-6151 serves as the preferred upgrade for older HOWO models experiencing recurring fuel delivery issues. Mechanics confirm this assembly resolves common problems like cylinder imbalance and incomplete combustion when retrofitted to earlier generation engines. Fleet managers document measurable fuel economy improvements of 3-5% after upgrading to this genuine 080V10300-6151 assembly.

Operational Benefits

Utilizing the 080V10300-6151 pipe assembly delivers measurable performance enhancements for HOWO operators. Engine efficiency improvements result from the precisely engineered internal surfaces that minimize hydraulic resistance within the fuel delivery path. This design feature reduces the workload on injection pumps, extending their service life while improving fuel atomization characteristics at the injector nozzles.

Drivers report noticeable smoother acceleration and more consistent power delivery across the RPM range after installing this 080V10300-6151 component. The balanced flow design prevents cylinder starvation during rapid throttle transitions, eliminating hesitation during gear changes. Noise reduction is another significant benefit – the dampening features incorporated into the assembly design lower combustion harmonics by up to 15% according to independent testing.

Fleet managers tracking operational costs confirm the 080V10300-6151 contributes to reduced maintenance expenses across multiple areas. More complete combustion results in cleaner exhaust systems with extended DPF service intervals. Consistent cylinder pressures reduce stress on connecting rods and bearings. Most importantly, preventing unexpected fuel system failures avoids costly roadside assistance calls and vehicle downtime.