OEM AZ2220000015 Transmission Front Housing for HOWO Truck

The OEM AZ2220000015 Transmission Front Housing is a critical structural component specifically engineered for HOWO heavy-duty trucks. As the primary protective enclosure for the transmission system, this precision-cast housing provides essential support for the gear assembly while maintaining proper alignment of rotating components. Manufactured to exact HOWO specifications, it ensures optimal power transfer efficiency and protects internal mechanisms from road debris and contaminants.

Constructed from high-grade aluminum alloy, the AZ2220000015 front housing offers exceptional durability without adding unnecessary weight to the drivetrain. This material choice provides superior heat dissipation properties that help maintain stable transmission temperatures during extended operation periods, especially important for long-haul trucking applications where HOWO vehicles excel. The precision machining of mounting surfaces guarantees leak-free sealing with mating components, preventing fluid loss that could lead to premature transmission failure.

Installing genuine AZ2220000015 components preserves the engineering integrity of HOWO transmission systems. The precisely calibrated dimensions ensure perfect fitment with existing gear assemblies and clutch mechanisms, eliminating potential vibration issues that might arise with aftermarket alternatives. Each housing undergoes rigorous quality verification, including coordinate measuring machine inspection of critical tolerances and pressure testing of sealed compartments to guarantee structural integrity under demanding operating conditions.

The transmission front housing serves multiple functional roles beyond structural support. It contains strategically designed oil channels that facilitate proper lubrication of bearings and gears while allowing efficient cooling fluid circulation. Bolt patterns and sealing surfaces maintain dimensional accuracy throughout thermal expansion cycles characteristic of heavy-duty operations. Maintaining original equipment standards ensures compatibility with existing service tools and reduces workshop installation time during replacement procedures.

Operational benefits of using the authentic AZ2220000015 component include extended transmission service intervals and reduced maintenance frequency. The precisely manufactured housing minimizes internal clearances while providing sufficient expansion tolerances for high-temperature operation. This balance prevents oil foaming while ensuring adequate lubrication film strength across various driving conditions experienced by HOWO trucks in different climates and terrains. Fleet managers recognize the AZ2220000015 specification as integral to achieving maximum powertrain longevity with minimal downtime.

Proper maintenance begins with visual inspection of the front housing during routine servicing. Technicians examine mounting surfaces for potential warpage and check seal engagement areas for scoring that might compromise fluid retention. Preventive measures include periodic cleaning of exterior cooling fins that facilitate heat dissipation from the transmission assembly. When replacement becomes necessary, following factory-recommended tightening sequences and torque specifications ensures optimal performance from the AZ2220000015 housing without inducing stress fractures.

Beyond its mechanical functions, the transmission front housing directly impacts fuel efficiency through precise internal clearances that reduce parasitic drag. Reduced friction losses translate to measurable cost savings over thousands of operating hours typical of commercial trucking applications. This economic advantage complements the extended service life achieved through original equipment quality, making the AZ2220000015 a critical investment in long-term operational efficiency.

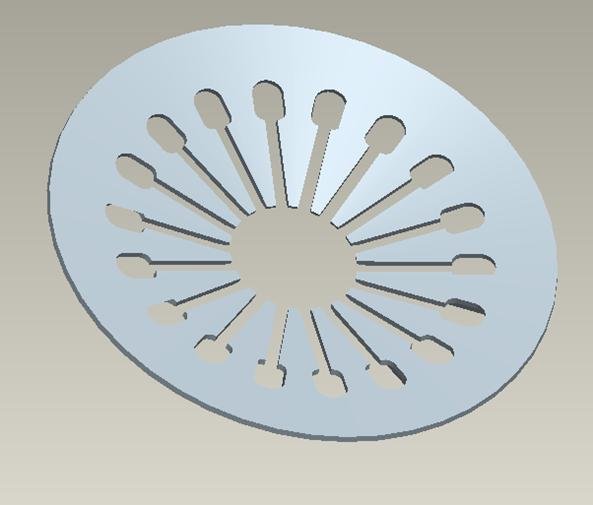

Engineering considerations in the AZ2220000015 design include resonant frequency damping characteristics that prevent harmonic vibrations from affecting gear meshing accuracy. This attention to dynamic behavior under load ensures consistent shift quality throughout the transmission speed range. Specific rib patterns cast into the housing structure provide targeted reinforcement where maximum stress concentrations occur during torque delivery cycles.

Durability testing exceeds standard industry requirements with simulated trials equivalent to 1,000,000 kilometers of operation in extreme temperature environments. These validation procedures verify material stability and dimensional retention under conditions more severe than typically encountered in real-world operations. Such extensive testing ensures the AZ2220000015 unit maintains sealing integrity and structural rigidity throughout its service life.

For HOWO fleets operating in varied geographic conditions, the housing’s robust design provides reliability in mountain operations where transmission oil temperatures frequently reach critical levels. The enhanced cooling properties incorporated into the AZ2220000015 design delay thermal degradation of lubricants and prevent seal hardening in cold regions. This thermal management capability reduces viscosity-related drag while maintaining protective oil films on moving components.

Maintaining inventory of authentic AZ2220000015 front housings supports fleet readiness with exact replacement parts that eliminate compatibility concerns. The standardized components integrate seamlessly with existing drivetrains without requiring adaptation kits or modifications that might void factory warranties. Consistent availability through authorized channels helps minimize vehicle downtime during scheduled maintenance or unexpected repairs.

Operators report improved shift quality and reduced noise levels when replacing worn housings with genuine AZ2220000015 units. The precise alignment restoration eliminates minor misalignments that create gear whine under load and improves overall powertrain refinement. These benefits complement the extended component life that comes with installing factory-specification parts designed specifically for demanding truck applications.

The manufacturing process for the AZ2220000015 incorporates advanced casting techniques that optimize material density throughout the housing structure. Pressure-controlled molds ensure consistent wall thickness in critical areas while eliminating porosity that could create structural weaknesses. Each casting undergoes non-destructive testing to verify internal integrity before machining to final dimensions.

Technical support documentation for the AZ2220000015 includes detailed installation procedures highlighting special considerations like seal lubrication recommendations and assembly sequence requirements. Technicians receive comprehensive guidelines for mounting surface preparation and fastener tightening patterns that prevent distortion during installation. Such support resources ensure proper implementation of replacement procedures.

Compatibility extends across multiple transmission versions specified for HOWO truck models sharing common bell housing patterns. This cross-model functionality simplifies spare parts inventory requirements for mixed fleets while maintaining quality standards consistent with original components. Identification markings cast into each AZ2220000015 housing provide traceability to production batches for quality tracking.

Logistical considerations include protective packaging designed to prevent shipping damage to precision machined surfaces. Custom foam supports protect mounting flanges and sealing channels during transport and storage until installation. Handling instructions emphasize careful positioning to avoid impact damage to critical sealing areas that might compromise performance.

In summary, the AZ2220000015 Transmission Front Housing represents an essential quality component in maintaining HOWO drivetrain reliability. The original specification part preserves engineering design intent while delivering measurable benefits in durability, efficiency and operational economy. Proper maintenance of this critical assembly extends transmission service life while ensuring consistent performance in demanding transport applications.