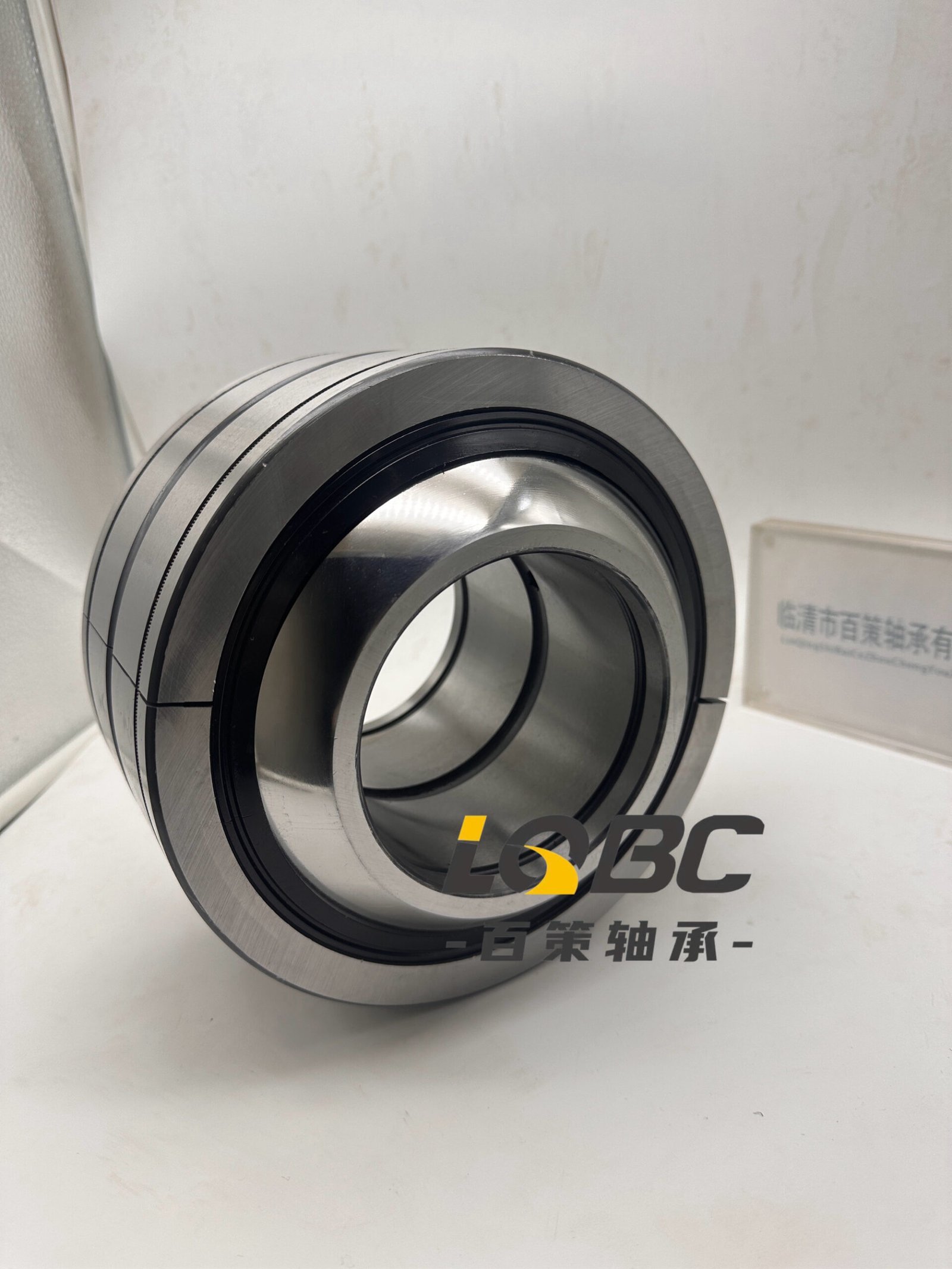

080-01100-6322 Crankshaft Housing Fully Machined for HOWO Truck Engine

Designed specifically for HOWO heavy-duty trucks, the fully machined crankshaft housing (OEM: 080-01100-6322) represents a critical component in the powertrain system. This precision-engineered housing provides the foundation for smooth engine operation and improved vehicle performance. Manufactured to exacting standards, the 080-01100-6322 unit ensures compatibility with various HOWO truck models, delivering reliability under demanding operating conditions.

The 080-01100-6322 crankshaft housing provides exceptional alignment precision for critical engine components. Its complete machining process ensures dimensional accuracy that meets original manufacturer specifications, making it a trusted replacement solution for workshop technicians. This component plays a vital role in maintaining the crankshaft’s positional integrity throughout the engine’s operational range.

Engineered for longevity, the 080-01100-6322 crankshaft housing effectively distributes mechanical stresses across the engine block. This reduces wear and fatigue in critical areas that typically compromise performance over time. With precise tolerances maintained throughout the manufacturing of the 080-01100-6322 housing, engine vibrations are minimized even during peak torque generation.

Core Features & Advantages

This 080-01100-6322 crankshaft housing incorporates advanced sealing surfaces that maintain optimal oil pressure integrity. The precision machining ensures consistent mating surfaces throughout all mounting points, preventing oil leaks that could lead to lubrication failure. Each 080-01100-6322 housing undergoes comprehensive dimensional verification for compatibility with designated HOWO powertrains.

Structural reinforcement is integrated into the design of the 080-01100-6322 unit, enhancing durability under continuous heavy-load conditions. These engineering considerations significantly extend the service interval potential when compared to standard replacements. The material composition of the 080-01100-6322 housing provides excellent thermal stability during temperature fluctuations.

Installation of the 080-01100-6322 crankshaft housing requires no special modification to existing HOWO engine blocks. The complete machining process guarantees precise alignment with surrounding components upon reassembly. This attention to detail in manufacturing the 080-01100-6322 part eliminates potential oil gallery obstruction issues.

Performance Applications

For fleet maintenance operations, the 080-01100-6322 crankshaft housing offers cost-effective repair solutions that restore original equipment performance standards. Compatibility covers numerous HOWO truck generations, making the 080-01100-6322 unit an essential inventory item for service centers. Its installation corrects alignment discrepancies caused by standard manufacturing tolerances.

The 080-01100-6322 housing improves oil circulation flow within critical bearing areas, enhancing overall lubrication efficiency. This function significantly reduces frictional wear between moving components throughout the engine assembly. Technicians installing the 080-01100-6322 component report improved oil pressure consistency at all operating speeds.

Designed for heavy-duty applications, the 080-01100-6322 crankshaft housing withstands extreme combustion forces produced by high-displacement engines. Rigorous testing of the 080-01100-6322 housing confirms structural integrity beyond standard operational parameters. This durability makes the 080-01100-6322 part particularly suitable for extended operation in challenging transport environments.

Maintenance Considerations

When replacing the 080-01100-6322 crankshaft housing, technicians should follow factory-recommended bolt torque sequences to maintain surface integrity. Proper installation procedures for the 080-01100-6322 unit include thorough cleaning of oil passages and verification of mating surface cleanliness. Failure to observe these procedures may compromise the performance of the 080-01100-6322 housing.

The dimensional stability of the 080-01100-6322 crankshaft housing remains consistent through temperature variations common in heavy-duty operations. This consistency prevents thermal distortion that leads to bearing clearance changes in conventional designs. Properly installed, the 080-01100-6322 component effectively maintains optimal oil film thickness under all operating conditions.

Unlike partial machining alternatives, the completely machined 080-01100-6322 crankshaft housing maintains geometric alignment throughout its structural profile. This comprehensive precision machining approach distinguishes the 080-01100-6322 housing from competing products. The consistency provided by the 080-01100-6322 unit reduces vibration transfer throughout the powertrain assembly.

Extended Value

Fleet maintenance managers report extended engine life cycles following installation of the 080-01100-6322 crankshaft housing in HOWO trucks. The precision engineering of the 080-01100-6322 component contributes to reduced wear in adjacent engine components, lowering overall maintenance expenses. Complete machining of the 080-01100-6322 housing minimizes operational vibrations that accelerate component fatigue.

Operational efficiency gains are measurable in vehicles equipped with the 080-01100-6322 crankshaft housing due to reduced parasitic energy loss. The rotational efficiency improvements achieved with the 080-01100-6322 unit directly translate to fuel economy benefits over prolonged operation periods. Consistent performance from the 080-01100-6322 housing ensures predictable maintenance requirements.

Replacement intervals for the 080-01100-6322 crankshaft housing align with major engine overhaul periods under typical commercial vehicle applications. This service synchronization simplifies maintenance planning by consolidating replacement schedules. Comprehensive machining throughout the 080-01100-6322 housing produces a surface finish that supports optimal oil retention properties.

Operational Resilience

The structural design of the 080-01100-6322 crankshaft housing incorporates reinforcing elements that withstand abnormal combustion events. This durability safeguards against potential engine failure modes that could result from extreme operating conditions. Installations of the 080-01100-6322 component demonstrate measurable reductions in engine noise levels at varying RPM ranges.

High-pressure oil distribution systems benefit from the precisely machined passages within the 080-01100-6322 crankshaft housing. This precision machining ensures consistent flow characteristics that meet original equipment performance standards. Operators maintaining fleets equipped with the 080-01100-6322 part report fewer bearing-related failures during scheduled maintenance inspections.

Technicians should apply manufacturer-specified sealants when installing the 080-01100-6322 crankshaft housing to maintain oil gallery integrity. Proper application prevents localized leakage points that compromise the functionality of the 080-01100-6322 unit. Adherence to these procedures ensures the full performance potential of the 080-01100-6322 housing.