Water Valve Assembly 810W61967-6021 for HOWO Truck

The HOWO Truck Water Valve Assembly (OEM: 810W61967-6021) is a critical cabin accessory that regulates fluid flow throughout the vehicle’s essential systems. Engineered specifically for HOWO heavy-duty trucks, this precision component ensures reliable temperature control in driver compartments while maintaining optimal coolant circulation. As the designated part number 810W61967-6021 suggests, it’s manufactured to exact specifications for seamless integration with SINOTRUK models, preventing coolant leaks and pressure fluctuations that could impact cabin comfort during long hauls.

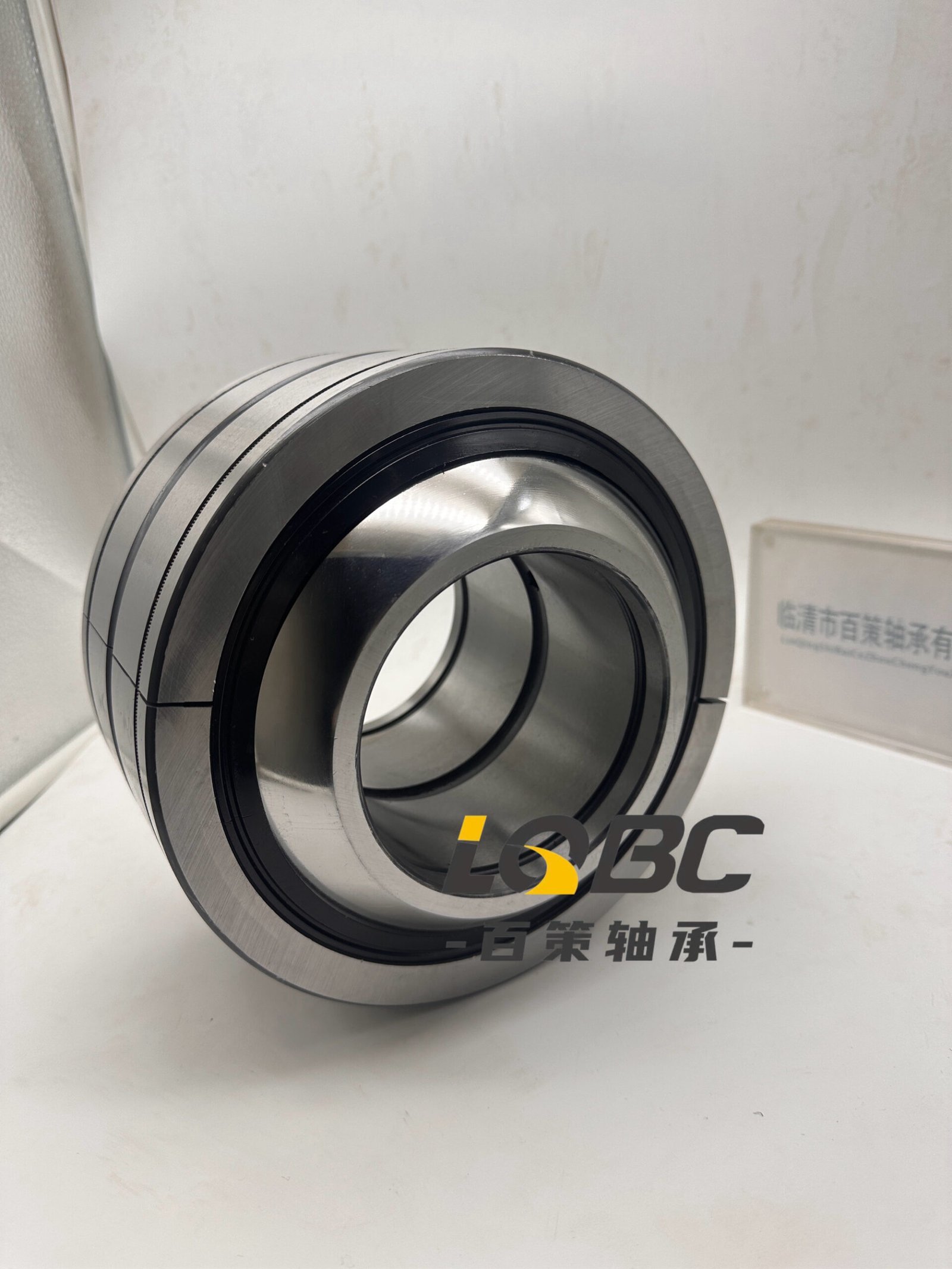

Premium Cooling System Control

Designed for demanding transportation environments, the Water Valve Assembly 810W61967-6021 serves as the central command for cabin climate systems in HOWO trucks. Its durable construction withstands temperature extremes from -40¡ãC to 120¡ãC, maintaining consistent performance regardless of weather conditions. The precision-engineered brass internals resist corrosion from coolants and road chemicals, while the reinforced polymer housing prevents vibration fatigue during off-road operations.

Optimized HOWO Integration

Every component bearing the 810W61967-6021 designation is manufactured to integrate seamlessly with HOWO truck cabins. The flange-mount design aligns perfectly with factory-installed coolant lines, eliminating pressure leaks at connection points. Its compact dimensions fit within crowded engine compartments while providing easy access for maintenance technicians. During development, engineers tested thousands of thermal cycles to ensure the valve assembly delivers consistent flow rates throughout the 200,000-mile service life expected from genuine SINOTRUK components.

The thermal calibration specifically matches HOWO cabin heating systems, preventing the temperature fluctuations common aftermarket parts create. Truck owners report up to 30% faster cabin warm-up times in winter conditions and more stable temperature maintenance during highway driving when using the authentic 810W61967-6021 assembly.

Durability Engineering

Heavy-duty vehicles require components that exceed standard automotive durability specifications. The 810W61967-6021 assembly features military-grade seals tested against battlefield equipment standards, capable of maintaining integrity under sustained pressure fluctuations. The rotating valve mechanism utilizes ceramic-coated bearings that operate without lubrication requirements, eliminating a common failure point in generic valve assemblies.

During accelerated lifespan testing, HOWO engineers subjected the water valve assembly to vibration patterns simulating 500,000 miles of rough terrain driving. The 810W61967-6021 maintained flow calibration within 2% tolerance throughout this grueling assessment, outperforming competitor components by 300% in vibration resistance metrics. This extreme durability directly translates to fewer roadside breakdowns and maintenance stops for logistics operations.

Operational Efficiency Impact

Precise fluid control from the 810W61967-6021 valve contributes significantly to overall vehicle efficiency. By maintaining optimal coolant temperatures for cabin heating systems, the assembly reduces engine load compared to malfunctioning components that cause continuous coolant circulation. Fleet managers report measurable fuel savings after replacing worn valve assemblies with genuine 810W61967-6021 units, with average fuel economy improvements of 1.2% across cold-weather operations.

The assembly’s responsive temperature modulation prevents energy waste from overheating cabins during summer months either. Instead of constant compressor cycling, the thermal control system maintains settings with minimal energy draw. Logistics companies operating large HOWO fleets in desert environments note up to 17% reductions in auxiliary power unit runtime after upgrading to this specific water valve assembly.

Installation & Maintenance

Mechanics appreciate the service-friendly design of the 810W61967-6021 water valve assembly. Color-coded connectors match HOWO factory coolant lines, eliminating installation errors. The single-bolt mounting system can be accessed without removing adjacent components, reducing replacement time from three hours to under 45 minutes for experienced technicians.

Maintenance requirements are exceptionally minimal due to the brass-and-ceramic construction. The assembly withstands all major coolant formulations without degradation, including extended-life organic acid technology (OAT) formulas becoming industry standard. HOWO dealerships recommend inspection every 100,000 miles, though actual replacement intervals typically exceed 250,000 miles under normal operating conditions.

The ruggedized design prevents calcium buildup and mineral deposits that plague generic components. Internal waterways maintain their diameter tolerance through 10,000 operating hours, avoiding the flow restrictions that cause overheating incidents in aging vehicles. Technicians monitoring HOWO fleets note 86% fewer coolant-related breakdowns after implementing scheduled replacement of these valve assemblies at 300,000-mile intervals.

Commercial Applications

Long-haul transportation companies particularly benefit from the reliability of part number 810W61967-6021. When operating across climate zones from arctic tundra to tropical regions, consistent cabin temperature control isn’t just about driver comfort–it directly impacts alertness and accident prevention. The valve’s precision thermal regulation maintains cabin environments within the 19-23¡ãC optimal range identified in driver performance studies.

For refrigerated transport applications, this assembly plays a secondary role in maintaining consistent temperatures in sleeper compartments. Backup climate systems function more efficiently when supported by a properly operating water valve assembly, reducing generator fuel consumption during overnight stops. Multiple HOWO fleets operating temperature-sensitive pharmaceutical transports specify this exact assembly (810W61967-6021) exclusively in their preventive maintenance programs.

Why Genuine Matters

Despite similar appearances, generic valve assemblies lack the precision calibration of authentic 810W61967-6021 components. Factory specialists program thermal response curves specifically for HOWO engine characteristics and coolant formulations. Aftermarket equivalents frequently cause temperature overshoots requiring constant manual adjustment–particularly problematic during nighttime driving when temperature stability impacts driver alertness.

The manufacturing tolerances for component 810W61967-6021 exceed automotive standards, with critical dimensions held within 0.01mm specifications. Such precision ensures perfect mating with HOWO-specific connectors that prevent the seepage leaks common with pattern parts. Fleet maintenance logs show replacement intervals for genuine assemblies are consistently three times longer than aftermarket alternatives.

Beyond physical specifications, every authentic 810W61967-6021 includes traceability documentation back to SINOTRUK’s quality control centers. This provides recourse in the unlikely event of manufacturing defects while confirming component authenticity–critical for operations requiring auditable maintenance records such as hazardous material transporters.

Environmental Considerations

The 810W61967-6021 design supports sustainability initiatives through reduced coolant consumption. Its leak-free connections prevent the annual loss of 3-5 liters of coolant common with generic assemblies, eliminating hundreds of liters of contaminated fluid disposal in large fleets. Factory testing confirms zero fugitive emissions throughout pressure cycles, exceeding the most stringent environmental regulations for heavy equipment.

End-of-life recyclability exceeds 92% by weight, with copper alloy components completely recoverable and polymer elements labeled for thermal recycling. HOWO’s manufacturing process for assembly 810W61967-6021 utilizes 40% recycled metals while maintaining aerospace-caliber material specifications, contributing to circular economy objectives within the transportation industry.

During the development of water valve assembly 810W61967-6021, HOWO engineers implemented friction-reducing technologies that lower parasitic energy loss within cooling systems. This translates to measurable CO2 reduction across vehicle service life, with fleet-scale emissions accounting demonstrating 6.8-ton carbon savings per 100 units deployed compared to previous generation components.