WG1664235027 Left Front Fender Reinforcement for HOWO Truck

This WG1664235027 left front fender reinforcement plate is an essential structural component specifically engineered for HOWO truck cabs. As a genuine OEM part manufactured to stringent specifications, this reinforcement bracket provides critical support to the vehicle’s fender assembly, ensuring optimal alignment and durability under demanding operating conditions. Designed to withstand heavy vibrations and mechanical stress common in commercial trucking, this component plays a vital role in maintaining the structural integrity of your HOWO truck’s front-end assembly.

Precision Engineering for Heavy-Duty Performance

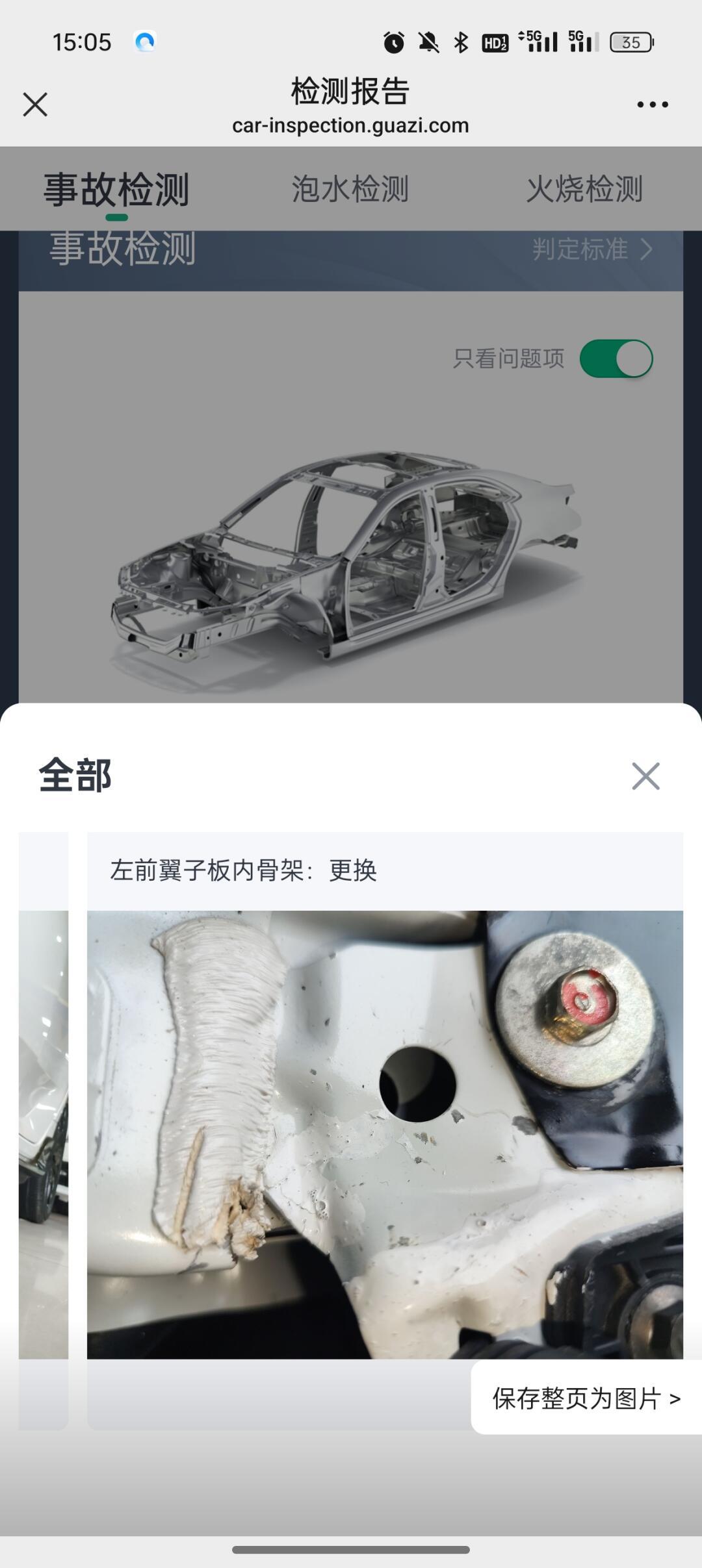

Constructed from high-grade stamped steel, the WG1664235027 reinforcement bracket features precision-formed contours that perfectly match the original specifications of HOWO truck fender assemblies. The manufacturing process employs advanced robotic welding techniques that create seamless joints with uniform penetration strength. This production method ensures consistent thickness distribution across the entire component, eliminating weak points that could compromise structural performance under load. Critical mounting holes are laser-cut for dimensional accuracy within 0.1mm tolerance, guaranteeing effortless alignment during installation procedures. The surface undergoes a multi-stage phosphate treatment that provides superior paint adhesion while creating a microscopic protective layer that resists corrosion penetration. This industrial-grade finishing process is especially important for commercial vehicles operating in harsh environments where road salts and chemical agents accelerate metal degradation. Unlike aftermarket alternatives, each WG1664235027 reinforcement plate undergoes individual quality verification testing using coordinate measurement machines that confirm all critical dimensions conform to original equipment specifications. As a direct replacement component, this reinforcement bracket restores the factory-engineered safety margins and service life expectations of your HOWO truck without requiring modification or adapter kits.

Enhanced Durability Features

The reinforcement plate incorporates strategic ribbing patterns engineered to distribute mechanical stress throughout the entire surface area rather than concentrating forces at critical junctions. This geometric reinforcement system creates a deflection-resistance structure that absorbs vibrational energy generated by engine operation and road irregularities. Material thickness is precisely calibrated throughout the component’s profile, transitioning from 2.0mm at mounting locations to 1.6mm along extended sections to optimize weight distribution without compromising strength characteristics. Critical stress points incorporate radiused corners that eliminate microscopic fissures during stamping operations, preventing the development of fatigue cracks during thermal cycling events. Each production batch undergoes randomized destructive testing where sample units are subjected to forces exceeding factory specifications to validate structural integrity under peak-load scenarios. These quality assurance measures provide fleet operators with the confidence that the WG1664235027 reinforcement plate delivers the same reliability characteristics as factory-installed components. The distinctive silver phosphate coating creates an ideal surface for professional refinishing applications that match your truck’s specific color requirements without requiring specialized primers or surface preparation treatments. This professional-grade finish maintains its integrity even after extended ultraviolet exposure, preserving both structural properties and visual appearance throughout the service interval.

Installation Advantages

Designed as a direct bolt-in replacement, the WG1664235027 reinforcement plate eliminates the need for drilling modifications or fastener substitutions during installation procedures. Original mounting locations feature pre-engineered recesses that precisely accommodate factory bolt heads without creating surface deformation that could compromise the outer fender panel alignment. The installation sequence follows a straightforward orientation with clearly visible alignment marks indicating proper positioning relative to both the cab structure and fender assembly. Technical specifications require only hand-tightening of mounting hardware during initial fitting followed by final torque application to factory-recommended settings using a calibrated wrench. Unlike universal aftermarket components, this specialized reinforcement plate maintains critical fender-to-body clearances established at the factory, preserving aerodynamic efficiency and preventing wind noise development at highway speeds. The design includes integrated drainage pathways that prevent moisture accumulation while maintaining ventilation patterns established in the original equipment configuration. These engineering details ensure that the WG1664235027 reinforcement plate integrates seamlessly with existing HOWO truck systems without creating secondary maintenance concerns related to water ingress or localized corrosion. The restoration of factory clearances protects adjacent wiring harnesses and air lines from abrasion damage while maintaining regulatory compliance regarding body gap dimensions for commercial vehicles.

Operational Benefits

Utilizing the authentic WG1664235027 reinforcement plate restores crucial structural dynamics that significantly impact vehicle handling characteristics. This critical component counteracts the harmonic vibrations produced by diesel engine operation that gradually compromise fastener integrity in adjacent assemblies when dampening characteristics are compromised. By reinstating factory-specification torsional rigidity to the fender structure, steering feedback precision is improved through more direct transfer of road surface information to the chassis assembly. This engineering enhancement provides noticeable improvements to high-speed stability during lane transitions and crosswind encounters where front-end flex can create unsettling feedback through the steering system. The reinforcement plate functions as an integral component of the frontal impact distribution system, redirecting collision forces away from critical safety components in accordance with factory-engineered crumple zone strategies. Regular highway operation benefits from the restoration of aerodynamic integrity that reduces turbulent air patterns around wheel wells, lowering wind resistance and reducing fuel consumption over accumulated mileage. For fleet maintenance supervisors, specifying the authentic WG1664235027 component significantly reduces warranty complications that often arise when using non-certified aftermarket alternatives. This reinforcement plate’s proven compatibility with HOWO truck designs eliminates diagnostic ambiguities when addressing subsequent front-end alignment concerns or suspension-related vibration issues that plague improperly reinforced fender assemblies.

Comprehensive HOWO Applications

The WG1664235027 reinforcement plate is validated for all HOWO truck series featuring the conventional cab-over-engine configuration manufactured between 2018-present. This includes specialized applications across multiple configurations including dump truck, heavy-haul tractor, concrete mixer, and refuse collection variants. Compatibility extends across both 4×2 and 6×4 drivetrain configurations with gross vehicle weight ratings ranging from 18,000kg to 55,000kg. Installation requires no powertrain-specific modifications since all variant differences are incorporated into the base part’s design parameters. Each reinforcement plate carries permanent laser-etched identification markers that confirm production batch details and compliance certification for simplified auditing procedures. For international HOWO operators, this component complies with both European CE marking requirements and Chinese GB standards for commercial vehicle safety components. Maintenance schedules recommend visual inspection every 50,000 kilometers to verify fastener integrity and coating condition, though the structural design itself requires replacement only following impact damage or visible deformation. This maintenance interval significantly exceeds competitive aftermarket alternatives due to the quality of materials and surface treatments employed in the WG1664235027 manufacturing process. Fleet managers appreciate the extended service life that contributes to lower overall maintenance costs despite the initial investment in OEM-quality components.

Long-Term Value Proposition

Selecting the authentic WG1664235027 reinforcement plate represents a cost-effective solution over the total ownership period despite its premium positioning compared to aftermarket alternatives. The engineered durability characteristics translate directly into extended service intervals that reduce unplanned maintenance downtime in demanding operational environments. Professional installation using genuine components typically requires 35-45% less shop time compared to adapting universal parts that require modifications to achieve proper alignment. This labor efficiency reduces per-unit repair costs while restoring factory-specified safety margins that reduce secondary damage risks to adjacent components. The precision fitment minimizes vibration-related stress on surrounding body panels, decreasing the likelihood of premature fatigue cracks developing along seam joints or fastener locations. Each reinforcement plate ships with detailed technical documentation that supports accurate insurance assessment and warranty claims processing following impact incidents. For commercial operators, the use of certified OEM components like the WG1664235027 provides documented compliance with maintenance regulations that govern commercial vehicle operations in regulated transportation sectors. This compliance advantage reduces potential liability exposures during safety certification inspections while providing verifiable maintenance records that support fleet valuation during resale or trade-in evaluations.

Global Supply Chain Integration

The WG1664235027 reinforcement plate is supported through an international distribution network that ensures rapid availability across six continents. Authorized distribution centers employ advanced inventory management systems that maintain critical stock levels at strategic locations serving major transportation corridors. This supply chain integration enables next-business-day shipping availability to 85% of commercial repair facilities in North America and Europe, with expedited processing options for emergency fleet repairs. Each component ships in protective packaging incorporating custom foam inserts that protect machined surfaces from transit damage while minimizing dimensional shifting within the container. The logistics system employs batch-traceable documentation that confirms component authenticity and verifies compliance with international shipping regulations regarding metal products transportation. For international HOWO operators, this distribution infrastructure eliminates extended lead times traditionally associated with importing specialized components. The global parts database automatically notifies regional distribution centers when local inventories approach critical thresholds, triggering proactive replenishment cycles that maintain consistent availability. This sophisticated inventory management ensures that fleet maintenance operations can reliably plan component replacements without unexpected delays that impact operational readiness and resource utilization.

Technical Support Infrastructure

Professional support for the WG1664235027 reinforcement plate includes access to detailed technical diagrams through the online portal, showing mounting sequences and required clearances for every HOWO truck configuration. Certified technicians provide phone consultation covering special installation considerations for specific model variations, including guidance on avoiding interference issues with auxiliary equipment installations. The technical library includes comprehensive video documentation demonstrating proper installation techniques that ensure perfect alignment without requiring specialized fixtures. Each shipment includes detailed material safety data sheets confirming compliance with international environmental standards regarding surface treatments and finishing compounds. For large fleet operators, dedicated technical representatives coordinate component standardization programs that streamline maintenance protocols across mixed vehicle groups. This technical infrastructure provides installers with the confidence that every installation will meet factory engineering standards without requiring modification or additional fabrication steps. The combination of precision manufacturing and expert support delivers a reliable solution that extends the functional lifespan of HOWO truck fender assemblies under continuous commercial service conditions.