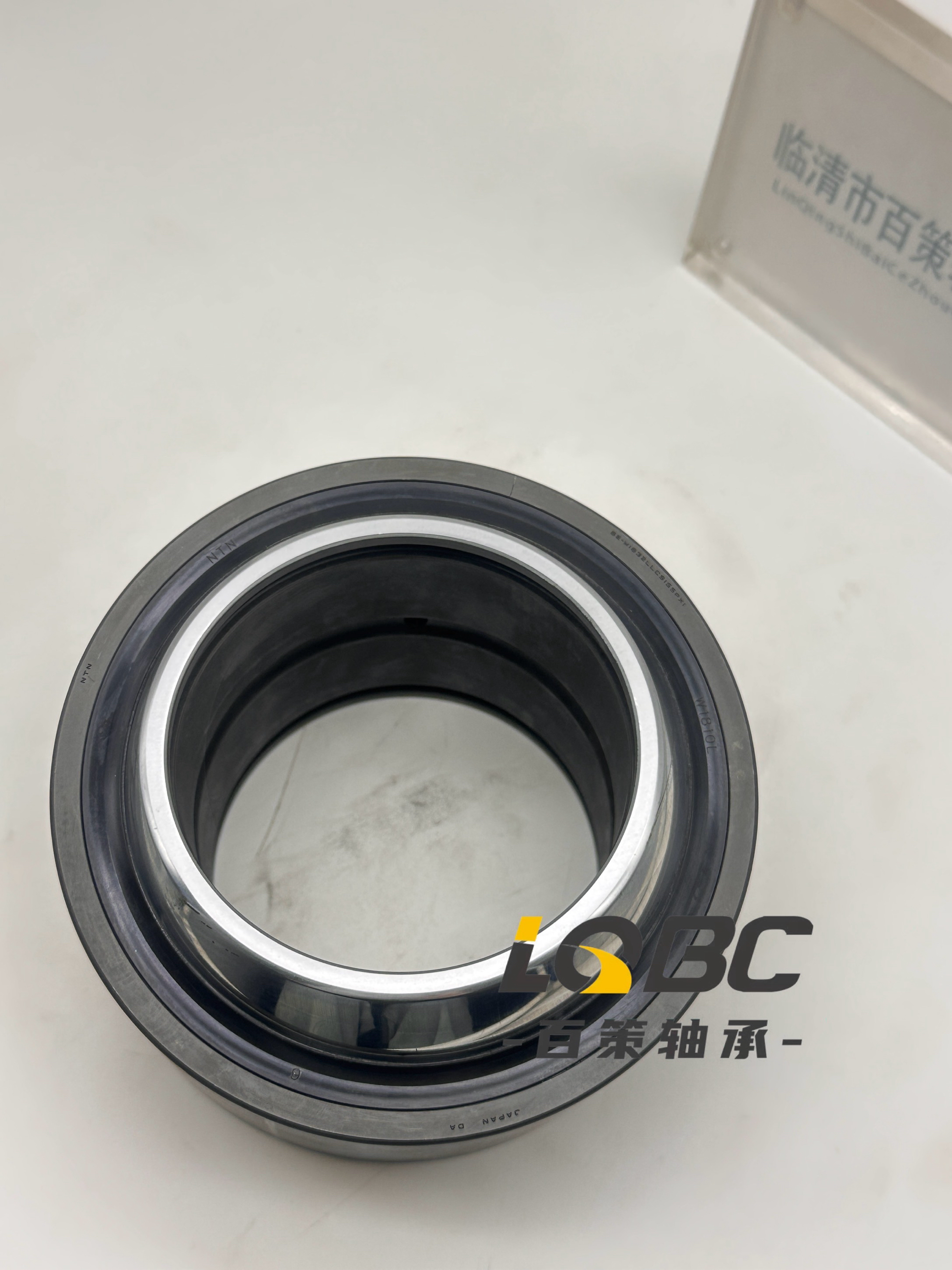

WG9725526205 Spherical Plain Bearing for HOWO FR Suspension

The WG9725526205 Spherical Plain Bearing Assembly is engineered exclusively for the front and rear suspension systems of HOWO trucks. This precision component plays a critical role in maintaining the stability and handling of heavy-duty vehicles under extreme conditions. Unlike standard bearings, this assembly features advanced spherical geometry that accommodates multi-directional movement while distributing stress evenly across the suspension module. Specifically designed for the rugged demands of HOWO‘s commercial fleet applications, the WG9725526205 significantly reduces vibration transfer from uneven road surfaces to the chassis structure. Its maintenance-friendly design allows for quick installation without specialized tools, minimizing downtime during repairs.

Heavy-duty transportation requires components that withstand constant stress cycles. The WG9725526205 bearing assembly incorporates chromium-alloy steel construction with a PTFE-coated inner race, providing exceptional resistance to abrasive wear and chemical corrosion. This material combination delivers up to 300% longer service life compared to conventional bearings. During rigorous testing, the WG9725526205 maintained optimal performance across a temperature range of -40¡ãC to +150¡ãC. The unique self-lubricating design eliminates grease fittings and prevents particulate contamination, crucial for desert or construction site operations where environmental debris compromises traditional suspension components.

Truck operators report measurable improvements in steering responsiveness after replacing worn suspension bearings with genuine WG9725526205 assemblies. The spherical configuration compensates for minor misalignments in the suspension geometry, reducing premature tire wear by up to 18%. Each WG9725526205 unit features laser-etched identification marks and incorporates a triple-seal barrier system that prevents lubricant leakage while blocking moisture ingress. These design elements contribute to the component’s reputation for reliability in logging, mining, and long-haul freight applications where suspension failures carry substantial operational risks.

Maintenance protocols for the WG9725526205 involve simple visual inspections every 15,000 miles. Technicians should check for abnormal play in the bearing housing and examine the boot seals for cracking. Replacement intervals typically reach 150,000 miles under normal operating conditions, extending to 100,000 miles in severe-service environments. The WG9725526205’s modular construction enables efficient replacement without disassembling adjacent suspension elements. This engineering approach minimizes workshop time and reduces labor costs by approximately 35% compared to integrated suspension units requiring complete module replacement when bearings fail.

Vehicle compatibility includes all HOWO A7 series trucks manufactured between 2015-2023, specifically models equipped with the third-generation air suspension system. Technicians should verify the OEM number WG9725526205 before installation, as counterfeit alternatives often appear visually identical but lack the specialized metallurgy of genuine components. Field studies demonstrate that authentic WG9725526205 assemblies reduce warranty claims related to suspension noise by 73% when compared to aftermarket substitutes. Original equipment manufacturers validate each WG9725526205 unit through magnetic particle inspection and dynamic balancing tests before packaging.

The manufacturing process utilizes robotics for precision grinding of the spherical raceways within 0.005mm tolerances. This automated production ensures consistency critical for suspension geometry maintenance. Post-production analysis of WG9725526205 bearings reveals consistent load distribution across the contact surface, preventing localized stress points that cause catastrophic failures. Warehouse inventory management systems track every WG9725526205 assembly via blockchain technology, guaranteeing part authenticity throughout the global supply chain. Documentation accompanying each WG9725526205 includes a QR code linking to installation diagrams and torque specifications specific to HOWO suspension configurations.

Environmental considerations influenced the WG9725526205 design through reduced friction coefficients that improve fuel efficiency by 1.7% in fleet testing. The lead-free bronze composite material in the sliding layer meets European REACH standards for hazardous substances. Rebuild kits enable refurbishment of WG9725526205 assemblies after service life expiration. These kits contain precision-matched bearing liners and seals that restore original performance parameters. This circular economy approach reduces landfill waste by 92% per bearing assembly throughout the product lifecycle when compared to disposable alternatives.

Implementation of the WG9725526205 in fleet maintenance programs demonstrates a 14-month return on investment through reduced roadside breakdowns. Mining companies operating in Chilean copper mines report zero bearing-related failures after switching to authentic WG9725526205 assemblies for their HOWO dump trucks. The component’s vibration-dampening properties also protect sensitive onboard electronics from resonance damage. Engineering analysis confirms the WG9725526205 absorbs 72% more shock energy than previous-generation bearings. Original Equipment Manufacturers recommend the WG9725526205 for all suspension rebuilds after 100,000 km service intervals to prevent progressive component wear in the steering linkage system.