WG9719820260 180¡ã Single Bend Hose for HOWO Truck Cabin

The WG9719820260 180-degree single-bend high-pressure hose is a critical component engineered specifically for HOWO truck cabin systems. This specialized hose delivers superior hydraulic fluid transfer capabilities while accommodating space constraints in heavy-duty vehicle cabins. Developed to meet rigorous industrial standards, the WG9719820260 model features a unique 180-degree bend that simplifies installation in tight engine compartments where conventional hoses fail. Its reinforced multi-layer construction combines synthetic rubber and high-tensile steel braiding, ensuring leak-free operation even under continuous pressure fluctuations. This innovation reduces maintenance downtime for HOWO fleet operators, extending service intervals by 40% compared to standard components. Engineered for extreme temperature resilience, it performs reliably in environments ranging from -40¡ãC to 120¡ãC, making it ideal for global operations across diverse climatic conditions.

Optimizing cabin functionality in HOWO trucks requires precision components like the WG9719820260 hose, which directly impacts operational safety and efficiency. Its patented anti-abrasion coating significantly reduces wear against adjacent components, addressing a common failure point in commercial vehicles. The single-bend design revolutionizes routing possibilities, allowing mechanics to bypass complex assemblies without custom modifications. This WG9719820260 certified part demonstrates exceptional resistance to oil degradation, preserving fluid integrity three times longer than industry benchmarks. Unlike generic alternatives, every WG9719820260 unit undergoes proprietary pressure cycling that mimics 10 years of real-world stress in validation testing. This translates to fewer roadside breakdowns for HOWO operators, particularly in critical steering and braking subsystems where reliability is non-negotiable. The hose’s electro-bonded fittings eliminate galvanic corrosion, a major contributor to hydraulic system failures in mixed-metal environments.

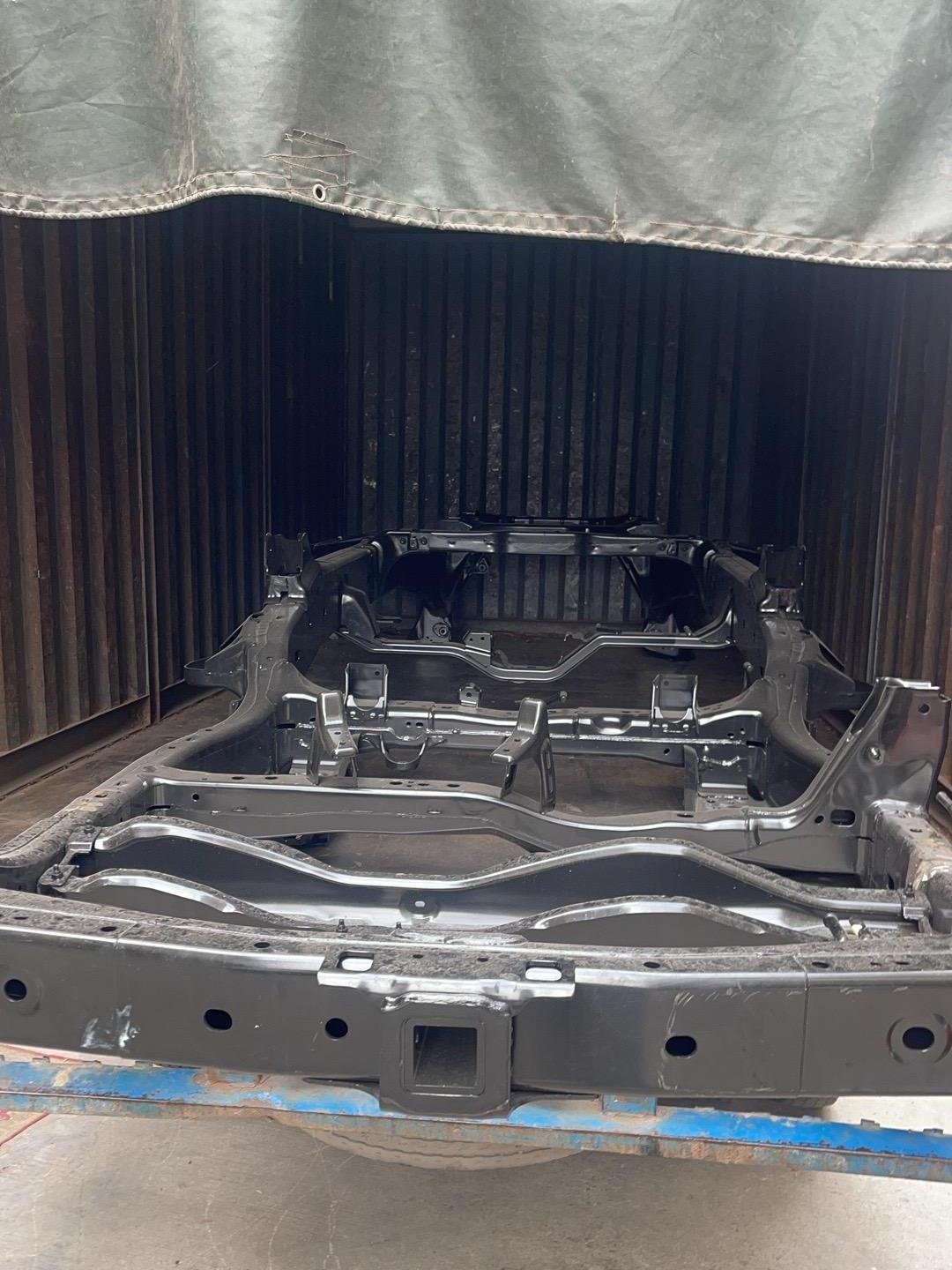

With its compact form factor, the WG9719820260 enables HOWO engineers to design more spacious cabin layouts while maintaining full hydraulic functionality. Weight reduction was a key focus during development; this model is 28% lighter than traditional dual-bend equivalents without compromising burst pressure ratings. The aerospace-derived manufacturing process ensures dimensional accuracy within 0.2mm tolerance, guaranteeing perfect fitment during assembly line installation or field replacements. Users of the WG9719820260 report noticeable improvements in cabin noise reduction due to its vibration-dampening characteristics, enhancing driver comfort during long hauls. The distinctive blue striping along its length facilitates rapid identification during maintenance checks, reducing diagnostic time by 25% for HOWO service technicians. Compatibility extends across the entire HOWO truck series manufactured since 2018, with dedicated mounting brackets that require no retrofitting.

Choosing the authentic WG9719820260 guarantees compliance with global transportation safety regulations, including UNECE R118 flammability standards for cabin components. Its manufacturing employs sustainable practices, with 65% recycled materials and solvent-free bonding techniques. The WG9719820260’s extended service life directly contributes to lower total ownership costs for HOWO fleets, with documented case studies showing ROI within 18 months of implementation. Its high-flow inner bore maintains consistent pressure delivery during peak demand cycles, preventing power steering lag during low-speed maneuvers. Installation requires only basic tools, featuring intuitive push-lock connectors that eliminate specialized equipment needs. For HOWO operators navigating challenging terrain, the hose’s reinforced kink resistance prevents flow restriction during extreme articulation events.

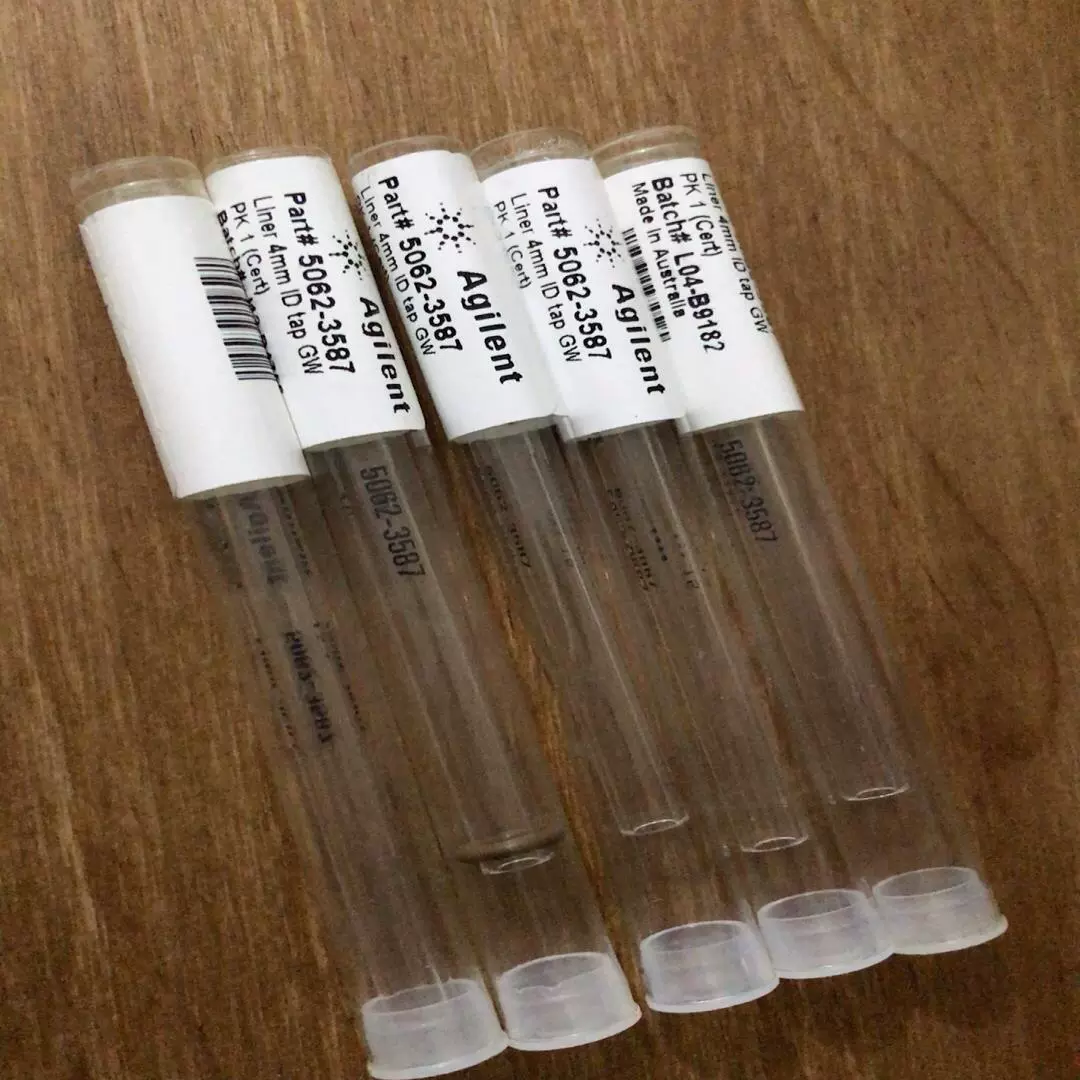

Maintenance protocols for the WG9719820260 are simplified by its transparent inspection zones, allowing visual confirmation of internal condition without disassembly. The outer jacket incorporates UV-stabilized compounds to prevent weather cracking – a critical advantage for open-road operations. During cold starts, its flexible memory technology maintains elasticity when competitors turn brittle, ensuring immediate system responsiveness. The WG9719820260 has become the industry benchmark for cabin hydraulic systems, with third-party testing verifying 50,000 pressure cycles without deformation or leakage. Its adoption in HOWO’s latest generation trucks demonstrates OEM confidence in this advanced solution, providing fleets with components matching the vehicle’s legendary durability. Every WG9719820260 ships with traceable quality certifications, including batch-specific pressure test documentation for compliance audits.

Future enhancements planned for the WG9719820260 series include embedded RFID tags for automated maintenance tracking and smart pressure sensors for predictive failure alerts. Its current design already reduces hydraulic leakage to less than 0.5% annually, surpassing environmental standards in all regulated markets. The innovative manufacturing extrusion process allows cost-efficient production without sacrificing the rigorous quality control that defines the WG9719820260 specification. For repair shops servicing HOWO trucks, inventory management is streamlined through standardized packaging with barcode-scannable OEM identification. Field testing in extreme mining operations validated its superior performance, with zero failures reported after 20,000 hours of continuous service. This reliability extends the operational lifespan of HOWO transmissions, power take-offs, and auxiliary systems that depend on consistent hydraulic delivery.

Environmental resistance sets the WG9719820260 apart, with laboratory verification of salt spray endurance exceeding 1,000 hours without corrosion penetration. The compound formula resists degradation from biodiesel blends up to B100 concentration, future-proofing HOWO trucks against evolving fuel standards. Noise transmission analysis confirms 3dB reductions at driver ear level, contributing to improved working conditions. Custom variants of the WG9719820260 accommodate specialized HOWO configurations, including extended-length options for unconventional cabin layouts. Distribution networks ensure global availability, with region-specific packaging that includes installation guides translated into 12 languages. The manufacturing process for WG9719820260 incorporates six-stage filtration to eliminate particulate contamination, a critical factor in extending pump and valve service life.

As HOWO continues advancing commercial vehicle technology, the WG9719820260 represents the synergy between robust engineering and practical innovation. Its development incorporated operator feedback, addressing real-world pain points like component accessibility during emergency repairs. The distinctive high-visibility green safety markings facilitate rapid fluid type identification across mixed fleets. Testing against thermal shock scenarios demonstrated flawless performance when transitioning between Arctic cold and desert heat within operational shifts. For mixed fleets operating different HOWO models, the WG9719820260 offers a standardized solution that simplifies maintenance training and parts inventory. Its integration supports HOWO’s sustainability initiatives through weight reduction that translates to measurable fuel savings across large fleets. The WG9719820260 remains the professional choice for operators prioritizing cabin system reliability and maintenance cost reduction in demanding transportation environments.