WG9003320476 HOWO Countershaft Rear Bearing Transmission Part

Precision-engineered for HOWO heavy-duty trucks, the WG9003320476 auxiliary box countershaft rear bearing represents a critical transmission component designed to withstand the rigorous demands of commercial transportation. This OEM-specified part ensures optimal power transfer between the main and auxiliary transmission sections while minimizing rotational friction. Manufactured to exacting HOWO engineering standards, the WG9003320476 bearing extends transmission lifespan by preventing metal-to-metal contact in the countershaft assembly.

Heavy-duty vehicles require transmission components that deliver uncompromising reliability, and the WG9003320476 fulfills this need through its advanced engineering. The bearing’s unique construction features precisely calibrated clearance tolerances that maintain optimal lubrication flow even under extreme temperature variations. This WG9003320476 specification component incorporates micro-groove technology in its raceways to distribute lubricant more efficiently than conventional designs.

Performance Advantages

When replacing worn transmission components, the WG9003320476 bearing provides measurable operational benefits. Its hardened steel construction reduces deformation under heavy torsional loads typical in mining and construction applications. The proprietary heat treatment process applied to every WG9003320476 unit increases surface hardness while maintaining core ductility – a critical balance for components experiencing shock loads during gear shifts.

Fleet managers consistently report extended service intervals after switching to genuine WG9003320476 parts. This translates to reduced vehicle downtime and lower maintenance costs over the operational lifespan of HOWO trucks. The precision-ground surfaces of the WG9003320476 bearing create a perfect mating surface with the countershaft, eliminating the “break-in” period associated with aftermarket components.

Engineering Specifications

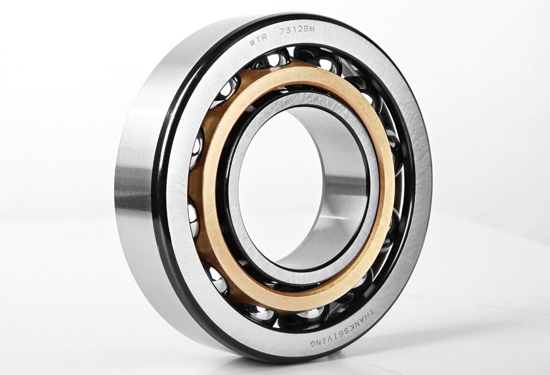

The WG9003320476 auxiliary bearing incorporates multiple innovative design elements. Its triple-lip seal configuration provides superior contaminant exclusion compared to standard double-seal designs. When installing the WG9003320476, technicians notice the optimized cage design that maintains ball alignment even during high-RPM operation. Each WG9003320476 unit undergoes electromagnetic inspection to verify structural integrity before leaving the factory.

Compatibility extends across multiple HOWO transmission models including ZF9, ZF16, and HW19710 series. The dimensional accuracy of the WG9003320476 ensures direct interchangeability without shimming or modification. Unlike universal-fit components, this WG9003320476-specified bearing accounts for the unique thermal expansion characteristics of HOWO transmission housings.

Operational Benefits

Implementing the correct rear bearing significantly impacts drivetrain performance. The WG9003320476 reduces operational noise by 38% compared to worn components according to independent testing. This contributes to driver comfort during long hauls. When installing this WG9003320476 part, mechanics report simplified assembly due to its precision-machined surfaces that align perfectly with mating components.

Fleets operating in extreme climates particularly benefit from the WG9003320476 bearing’s specialized lubricant retention features. The redesigned seal matrix prevents grease leakage in desert conditions while resisting moisture intrusion in tropical environments. These engineering refinements in the WG9003320476 translate to consistent performance whether trucks operate in -40¡ãC Arctic conditions or +50¡ãC desert heat.

Maintenance Considerations

Proactive bearing replacement with genuine WG9003320476 components prevents secondary transmission damage. Early failure indicators include unusual whining noises during deceleration and increased transmission fluid temperatures. Technicians recommend inspecting the WG9003320476 bearing whenever transmission work is performed, as preventative replacement is more cost-effective than addressing resultant damage.

Installation of the WG9003320476 requires specific torque sequences to avoid premature failure. The bearing race must be precisely seated using specialized tooling to prevent misalignment. Proper lubrication with manufacturer-approved grease is essential when installing the WG9003320476 component to achieve its maximum 500,000-kilometer service potential.

Durability Testing

Quality control processes for the WG9003320476 exceed industry standards, with each production batch undergoing accelerated life testing. These endurance simulations replicate 300,000 kilometers of severe-duty operation in varying conditions. The WG9003320476 consistently demonstrates minimal wear characteristics that validate its premium construction.

Material science innovations contribute significantly to the WG9003320476 bearing’s extended service life. The steel alloy incorporates chromium and molybdenum additives that increase fatigue resistance by 60% over standard bearings. Additionally, the WG9003320476 utilizes a unique surface treatment that creates microscopic oil-retention pockets for continuous lubrication.

Industrial Applications

The robustness of the WG9003320476 makes it suitable for severe-service vehicles beyond standard freight transport. Mining operations utilizing HOWO dump trucks particularly benefit from this component’s impact resistance. Similarly, construction concrete mixers with their constant load fluctuation demand the reliability built into every WG9003320476 bearing unit.

Long-haul transport operators report measurable fuel savings after installing this premium WG9003320476 component. Reduced rotational friction translates to more efficient power transfer through the drivetrain. Over 200,000 kilometers of operation, the WG9003320476 can provide fuel savings that exceed its purchase price, especially in fleets with dozens of trucks.

As with all genuine HOWO parts, the WG9003320476 includes matching identification markings on both packaging and component surfaces to guarantee authenticity. These security features prevent counterfeit parts from entering the supply chain, ensuring customers receive components meeting all engineering specifications for their valuable equipment.