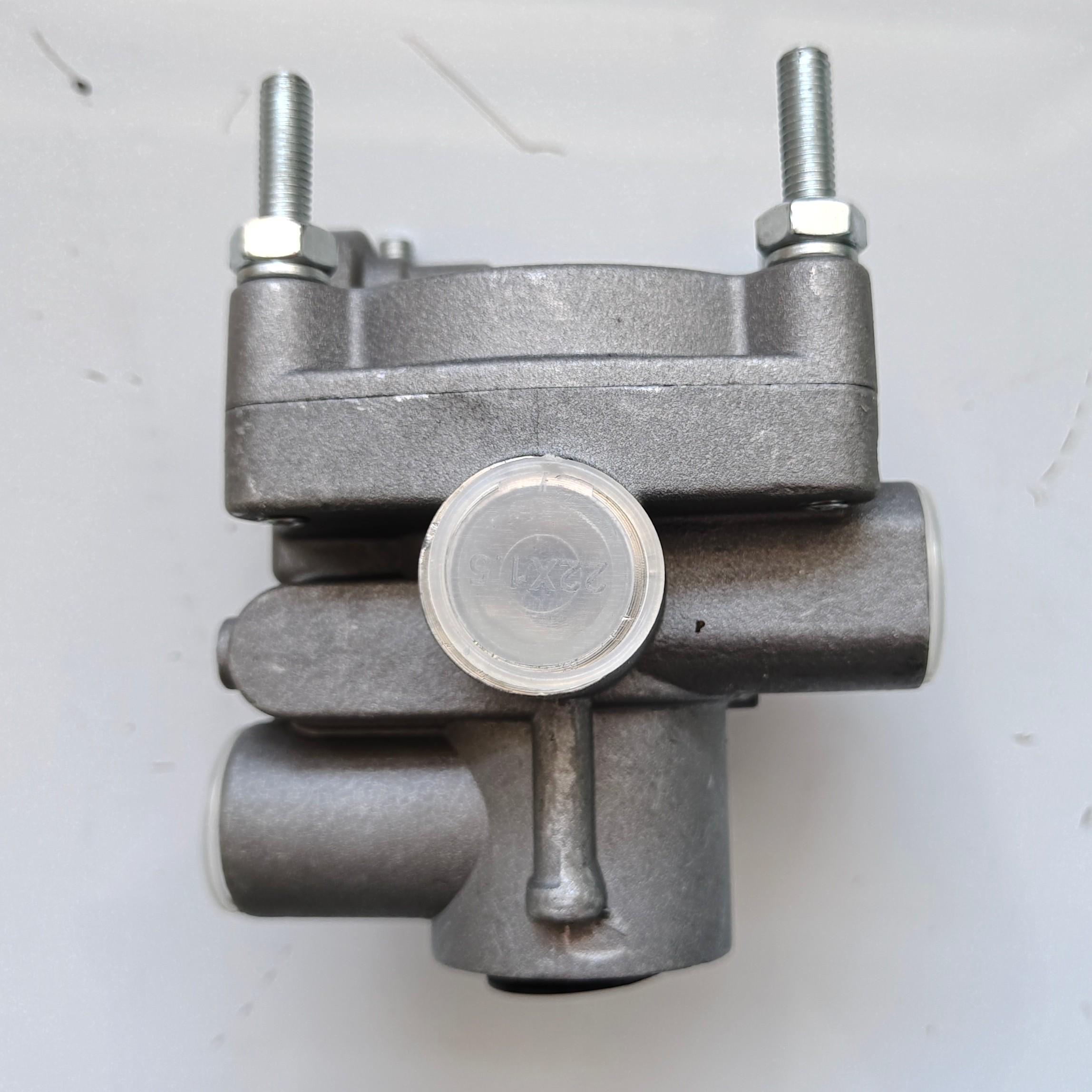

WG9000360524 Relay Valve for HOWO Truck Brake Module

The WG9000360524 Relay Valve is an essential component in the brake module of HOWO trucks, designed specifically to optimize braking performance and safety. This precision-engineered relay valve ensures consistent pressure regulation throughout the braking system, providing reliable operation in all driving conditions. As a critical safety component in HOWO‘s advanced braking architecture, it serves as the central nervous system that coordinates pressure distribution between the service brakes and spring brakes.

Optimized Braking Performance

Engineered specifically for heavy-duty applications, the WG9000360524 Relay Valve provides instantaneous response to driver inputs, ensuring precise modulation of braking force. Its advanced diaphragm design reduces pressure lag while maintaining consistent braking performance, even during prolonged downhill descents. The valve’s corrosion-resistant construction withstands harsh environmental conditions, preventing premature failure and reducing maintenance requirements.

Reliability in Diverse Conditions

Whether navigating urban streets or traversing rugged terrain, this relay valve delivers uncompromised performance. Its temperature-resistant components maintain operational integrity from -40¡ãC to 120¡ãC, ensuring reliable braking in extreme climates. The WG9000360524 undergoes rigorous quality validation to meet international safety standards, with each unit precision-tested for leak integrity and pressure response before installation.

Seamless Compatibility

The WG9000360524 is designed as a direct replacement part for original equipment installations. Its precise dimensions and connection specifications ensure perfect fitment without modifications, eliminating compatibility issues during brake system service. The valve’s standardized mounting configuration allows for straightforward installation, reducing workshop time and preventing installation errors.

Enhanced Safety Features

Incorporating multiple redundancy pathways, the WG9000360524 provides failsafe operation through its innovative pressure-balancing chambers. During emergency braking situations, the valve automatically prioritizes pressure delivery to critical braking circuits. Its self-diagnostic functionality monitors internal components for potential degradation, providing early warning indicators for preventative maintenance.

Operational Efficiency

The WG9000360524 Relay Valve significantly improves brake system efficiency through its precision-machined airflow channels that minimize pressure loss. Optimized response characteristics ensure balanced braking force distribution across all wheel positions, reducing tire wear and preventing uneven braking. This translates to lower operating costs and extended service intervals for transportation fleet operators.

Design Specifications

Manufactured from high-grade aluminum alloy with stainless steel reinforcement at stress points, the valve provides exceptional durability. Internal components utilize specialized rubber compounds resistant to oil degradation and ozone exposure. The compact dimensions of the WG9000360524 allow for flexible mounting positions within crowded chassis environments while maintaining access for serviceability.

Maintenance Considerations

With its accessible service ports and modular component design, the WG9000360524 Relay Valve supports convenient maintenance. The field-replaceable diaphragm assembly and seat kits allow for in-vehicle repairs without complete removal. Protective boots shield critical shafts from debris accumulation, preventing premature wear and corrosion of moving parts that could compromise valve operation.

Performance Verification

Third-party validation confirms the WG9000360524 exceeds industry standards for response time and pressure stability. Bench testing demonstrates consistent performance through 500,000 actuation cycles without degradation in operational parameters. Accelerated environmental testing verifies resilience against salt spray, vibration harmonics, and thermal cycling at levels exceeding standard duty cycles.

Fleet Management Applications

Transport operators utilize the reliability of the WG9000360524 to maintain consistent brake performance across mixed vehicle fleets. Its standardized configuration allows for uniform spare parts inventory, reducing storage requirements and training costs for maintenance teams. The predictable service life enables optimal scheduling for preventative replacement programs.