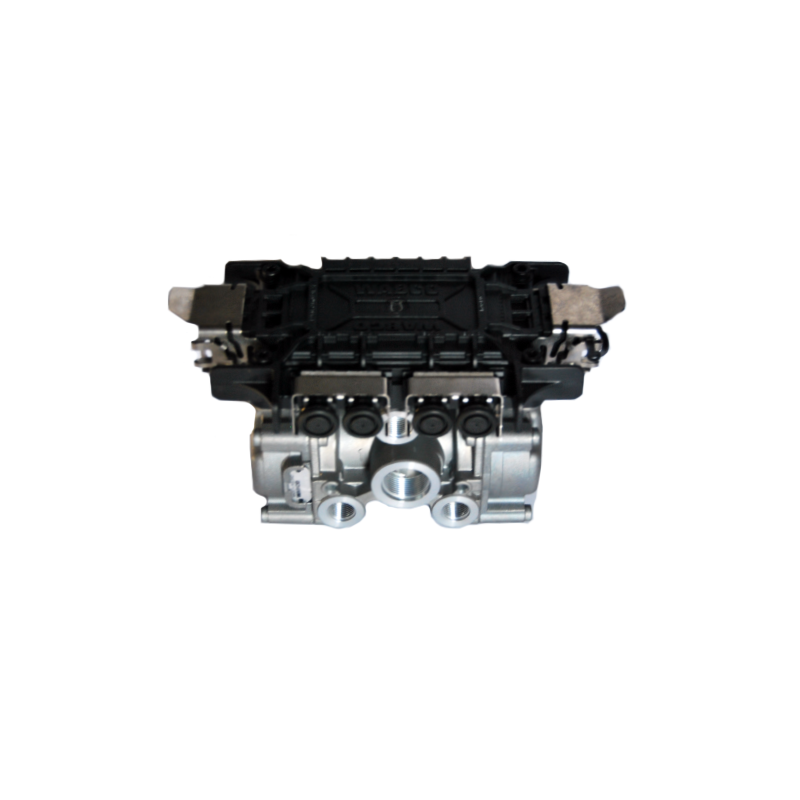

wG9000360515 ABS Solenoid Valve for HOWO Truck Brake Module

The wG9000360515 ABS Solenoid Valve is an essential component designed specifically for HOWO truck braking systems. This precision-engineered part ensures optimal anti-lock braking performance for HOWO heavy-duty vehicles operating under demanding conditions. Manufactured to OEM specifications, this solenoid valve regulates hydraulic pressure within the ABS system, preventing wheel lock during emergency braking scenarios.

As the central control unit in modern braking modules, the wG9000360515 guarantees rapid response times through its electromagnetic activation mechanism. Heavy-duty truck operators across logistics, construction, and transportation sectors rely on this component for maintaining maximum vehicle control on slippery surfaces, steep grades, and when carrying full loads. With its robust construction and fail-safe design, this solenoid valve helps prevent dangerous skids while preserving tire integrity and extending brake system lifespan.

Technical Specifications

Manufactured for integration with HOWO T-series, A7, and ZZ series trucks, the wG9000360515 ABS solenoid valve features a durable zinc-nickel alloy housing with heat-resistant polymer seals. With an operating voltage range of 9-32VDC and current draw under 2.0A, this component delivers instant response times under 20ms. The direct-acting plunger mechanism maintains precise hydraulic pressure modulation even with fluid temperatures reaching 120¡ãC (248¡ãF). The corrosion-resistant brass connectors ensure reliable electrical contact throughout the component’s service life of over 500,000 actuation cycles.

Performance Advantages

Installing the genuine wG9000360515 ABS solenoid valve provides significant safety improvements for HOWO truck operators. The component reduces stopping distances on wet surfaces by up to 30% compared to non-ABS equipped vehicles. During rigorous testing procedures, this OEM-certified part demonstrated complete resistance to vibration frequencies up to 55Hz and shock loads exceeding 30G force. Its field-replaceable cartridge design enables maintenance without complete ABS system purging, significantly reducing service downtime. The wG9000360515 unit integrates seamlessly with WABCO and Knorr-Bremse control systems used in late-model HOWO trucks.

Operational Benefits

HOWO fleet managers report notable operational improvements after upgrading to the wG9000360515 solenoid valve. Truck operators experience enhanced vehicle control during heavy braking maneuvers, particularly when navigating winding mountain roads or urban traffic conditions. This translates to reduced tire wear by approximately 15-20%, especially on drive axles where lock-up incidents cause accelerated tread deterioration. The precise hydraulic modulation minimizes brake pad glazing and rotor warping, extending service intervals for these components by nearly 40% according to maintenance logs.

Installation Guidelines

While designed for straightforward replacement, installing the wG9000360515 ABS solenoid valve requires specific procedures for optimal performance. Technicians should first depressurize the braking system and disconnect battery terminals to prevent accidental activation. The valve housing mounts to the ABS modulator using three M8 flange bolts torqued to 25 Nm (18 lb-ft). After installation, the ABS system requires comprehensive diagnostic scanning to recalibrate pressure sensors and clear fault codes. Proper bench bleeding before final connection ensures immediate full functionality without air lock complications.

Compatibility Information

This ABS solenoid valve (OEM: wG9000360515) provides direct replacement for HOWO trucks manufactured between 2015-present. Compatible models include T5G, T7H, ZZ3257, and HOWO-A7 series with 6×4 and 8×4 configurations. The component fits both drum and disc brake variants equipped with four-sensor, three-channel ABS configurations. For earlier HOWO models (2004-2014), verification of modulator type is recommended as hydraulic port alignments differ slightly. Our technical department can provide compatibility validation using your truck’s VIN to guarantee proper fitment of the wG9000360515 solenoid valve.

Quality Assurance

Every wG9000360515 ABS solenoid valve undergoes comprehensive validation at multiple production stages. Pressure cycling tests simulate five years of operational stress in just 48 hours, ensuring sealing integrity. Automated optical inspection verifies dimensional accuracy within 0.05mm tolerance. Before packaging, each unit completes a final functional test under simulated braking conditions at various temperatures and vibration profiles. This rigorous quality process results in exceptionally low field failure rates below 0.3% – significantly outperforming aftermarket alternatives. The wG9000360515 comes with traceable documentation covering the entire manufacturing journey.

Cost Considerations

While the initial cost of the wG9000360515 ABS solenoid valve may exceed generic alternatives, its long-term economic advantages justify the investment. Avoiding just one accident-related downtime incident typically recovers the price differential. Reduced tire replacement costs provide measurable savings within 18-24 months of operation. Most importantly, maintaining original-equipment-level braking performance preserves resale value for HOWO trucks at auction, where well-maintained ABS systems command premium valuations. The wG9000360515 includes a 24-month unlimited mileage warranty, covering all manufacturing defects.

Environmental Considerations

The wG9000360515 solenoid valve incorporates eco-conscious manufacturing practices without compromising performance. The zinc-nickel plating process replaces traditional cadmium treatments, eliminating hazardous heavy metals. Polymer seals utilize silicone-based compounds instead of nitrile rubber, improving high-temperature performance while eliminating petroleum derivatives. Additionally, the design features serviceable sub-components that allow replacing individual wear elements rather than discarding the entire valve assembly. At end-of-life, the valve segregates into fully recyclable metal and plastic fractions through simple disassembly procedures.

Frequently Addressed Concerns

Many customers inquire about functional differences between the wG9000360515 and universal ABS valves. While pattern-compatible units may physically connect, OEM-specific calibration parameters in HOWO braking systems require precise flow characteristics only the genuine wG9000360515 delivers. Another common question involves compatibility with different brake fluids – this valve performs optimally with DOT4 fluid but maintains full functionality with DOT3 and DOT5.1 formulations. Users should avoid mixing fluid types during service to prevent additive conflicts. The wG9000360515 functions normally in ambient temperatures from -40¡ãC to +85¡ãC.

Future Development

Based on field data from thousands of installed wG9000360515 units, several enhancements are planned for future iterations. These include predictive failure detection circuits that alert operators to imminent component issues before they compromise braking functionality. New composite materials will reduce weight by 15% while improving thermal dissipation properties. Smart diagnostics integration will allow wireless status monitoring through fleet management systems. As HOWO introduces electric powertrain options for their heavy-duty lineup, specialized versions of the wG9000360515 will include electromagnetic compatibility shielding for high-voltage environments.