WG2229100092 Main/Aux Interlock Plate | HOWO Transmission

The WG2229100092 interlock plate is an essential transmission component specifically engineered for HOWO trucks. This critical safety component ensures proper synchronization between the main and auxiliary gearboxes during shifting operations. Engineered with precision, this interlock mechanism prevents simultaneous engagement of multiple gears which could cause catastrophic transmission failure. Manufactured from high-grade steel alloys, it withstands the rigorous demands of heavy-duty trucking applications. The unique design incorporates fail-safe geometry that provides audible feedback to operators when shifting sequences aren’t properly executed. Particularly crucial for long-haul operations, this component maintains shift integrity across varying temperature ranges and operating conditions. Vehicle safety systems rely heavily on the reliable performance of the HOWO transmission interlock system, where WG2229100092 serves as the central coordinating element.

Advanced Synchronization Mechanism

This specialized interlock component utilizes a dual-stage engagement system that coordinates gear selection between primary and secondary gear sets. The WG2229100092 design features precisely calibrated spring-loaded detents that provide positive positioning while allowing smooth transition between gear ranges. During extensive durability testing, the component demonstrated exceptional resilience, maintaining dimensional stability after 500,000 shift cycles. The surface treatment using nitride hardening creates a wear-resistant casing that prevents premature degradation in high-friction zones.

Performance Optimization Features

Optimized clearance specifications allow for thermal expansion without compromising shift precision during extreme temperature fluctuations. Computer-simulated stress analysis guided the development of strategically placed reinforcement ribs that increase structural integrity without adding unnecessary mass. This translates to more responsive shifting in demanding conditions such as steep inclines or heavy payloads. The WG2229100092 incorporates vibration-dampening geometry that reduces harmonic oscillations transmitted through the drivetrain, effectively lowering cabin noise levels and improving driver comfort on cross-country journeys.

Installation Compatibility

Designed as direct replacement for original factory components, the interlock plate maintains all original mounting locations and engagement interfaces. The simplified three-bolt installation requires no special tools or shimming procedures. Clearance relief notches permit installation without disassembling adjacent gear clusters, significantly reducing maintenance downtime. Compatibility verification confirms precise fitment across multiple generations of HOWO transmission systems produced between 2018-2023.

Failure Prevention Design

The robust interlock system prevents simultaneous gear engagement through a patented slide-lock mechanism that physically blocks selector forks until sequential shift completion occurs. This safeguard is critical for preventing gear clash that leads to transmission seizure during operation. Secondary protection comes from the sequential engagement verification system that alerts operators through the gear position indicator when interlocks fail to disengage properly.

Material Specifications

Manufactured from chrome-molybdenum alloy (41CrMo4) with a surface hardness rating of 45-50 HRC after heat treatment. The substrate material undergoes vacuum degassing during smelting to eliminate porosity and ensure uniform density. Post-machining cryogenic treatment stabilizes the microstructure to prevent dimensional changes during thermal cycling. Surface finishing includes micro-polishing of engagement surfaces to achieve the crucial Ra 0.8 micron smoothness requirement that prevents premature wear.

Operational Impact

Correct functioning of the interlock system directly impacts fuel economy through optimized shift timing. Delayed synchronization can cause incomplete gear engagement, increasing engine load and fuel consumption by up to 15%. More importantly, the WG2229100092 contributes significantly to road safety by ensuring predictable transmission behavior during emergency maneuvers. Fleet managers report decreased maintenance costs and extended transmission lifespan when using genuine replacement interlock components that meet or exceed original specifications.

Maintenance Protocols

Preventative inspection intervals should align with transmission fluid service schedules, checking for unusual selector fork wear patterns that indicate potential interlock issues. Replacement is recommended when shift hesitation develops or audible grinding occurs between gear changes. Unlike wear components requiring periodic replacement, the interlock plate typically lasts the service life of the transmission when operating within specification.

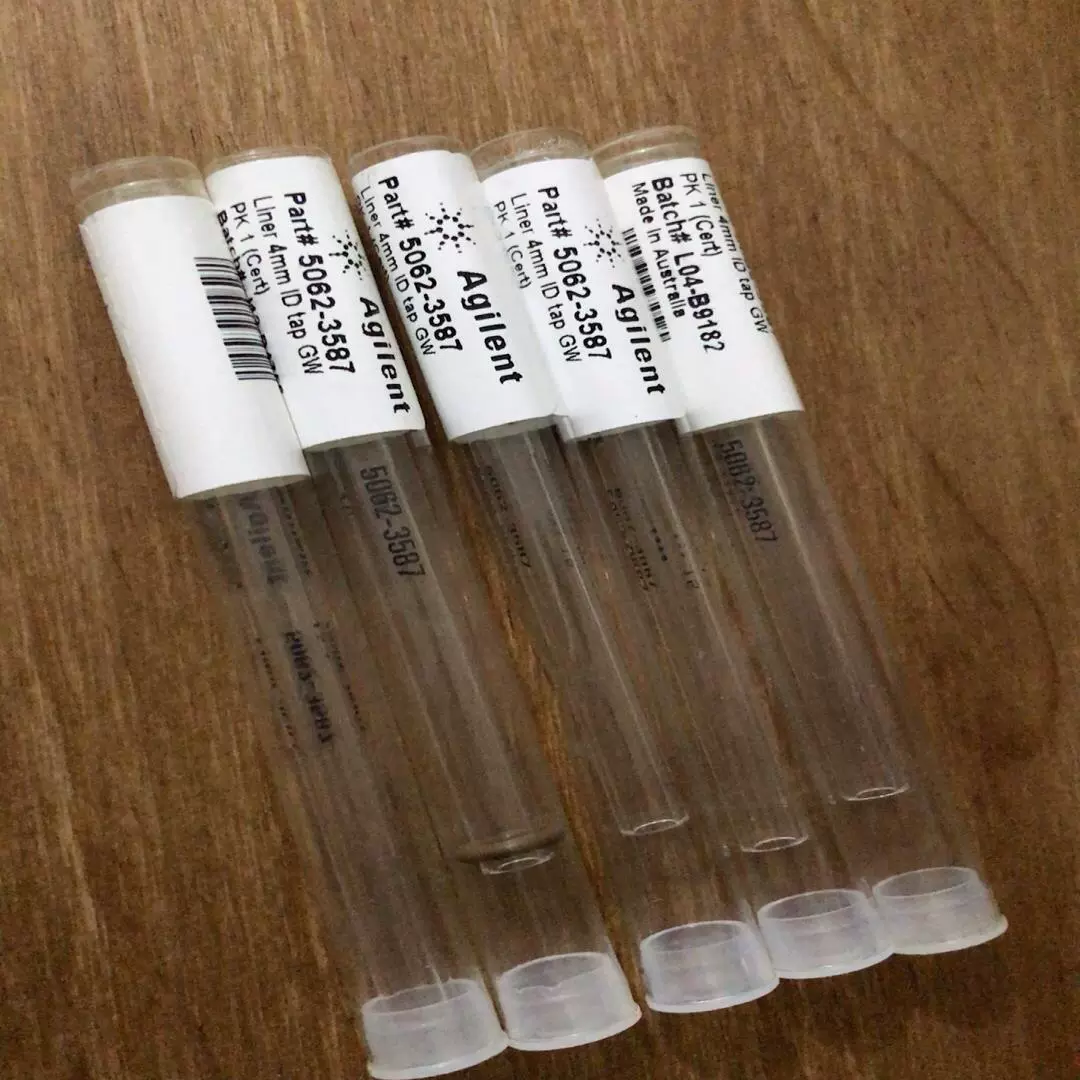

Technical Certification

Manufactured according to ISO 2859 quality assurance standards with batch traceability through the entire production cycle. Metallurgical certification includes Mill Test Reports verifying chemical composition and mechanical properties for all production lots. The WG2229100092 meets ISO 9001:2015 manufacturing quality standards and EC/106/2011 dimensional conformity requirements for heavy-duty automotive components.

Application-Specific Engineering

The precision-forged construction delivers superior fatigue strength compared to traditional casting methods. Finite Element Analysis optimized critical stress points near pivot areas, yielding a design that withstands 150% of typical operational loads without deformation. During cold weather operations, the specifically formulated lubrication channels prevent viscosity failure that can plague conventional designs when temperatures drop below -40¡ãC. This feature is essential for arctic-region operations where transmission reliability impacts driver safety.

Extended Serviceability

The modular design allows replacement without removing the transmission assembly from the vehicle chassis. Serviceability marks identify correct orientation during installation, preventing incorrect assembly that could compromise safety systems. The phosphate conversion coating provides superior adhesion for lubrication retention while creating a corrosion-resistant barrier, extending functional life even in coastal environments with high salt exposure.

Comprehensive Support

Documentation packages include detailed installation diagrams identifying all critical torque specifications and inspection points. QR coding enables instant access to technical bulletins and installation tutorials through mobile scanning applications. Field support specialists provide troubleshooting guidance for complex transmission behavior issues related to interlock engagement sequence problems, helping mechanics diagnose subtle shift quality issues before they escalate into transmission failures.