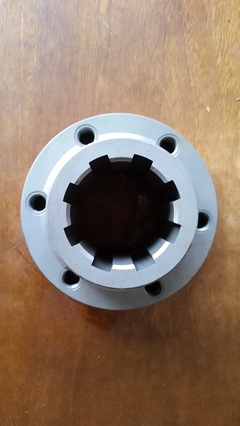

wG2210100035/1 HOWO Output Flange 180 Face Teeth

The HOWO truck series requires precision-engineered transmission components for optimal performance in demanding conditions. This wG2210100035/1 Output Flange with 180 face teeth plays a critical role in power transfer systems, specifically designed for HOWO heavy-duty applications. As the interface between transmission and drivetrain, this output flange ensures torque is efficiently delivered to the wheels while maintaining structural integrity under extreme loads. The unique 180-tooth configuration provides superior engagement with mating components, reducing vibration and preventing power loss during operation.

Engineered to exact HOWO specifications, the wG2210100035/1 flange features induction-hardened teeth surfaces that significantly extend service life. The thermal treatment process creates a wear-resistant layer while maintaining the core material’s toughness, providing exceptional resistance against pitting and deformation. This dual-property approach is vital for transmission components subjected to constant meshing forces and shock loads during start-stop operations in commercial vehicles. Unlike generic alternatives, each tooth profile undergoes precision machining to guarantee perfect contact patterns across the entire gear face.

Compatibility is ensured through strict adherence to original HOWO transmission dimensions. The wG2210100035/1 output flange maintains critical interface specifications including pilot diameter, bolt circle pattern, and spline dimensions. This attention to detail means zero modification is required during installation – simply replace your worn component with this direct-fit solution. The flange’s balanced design reduces harmonic vibrations that can accelerate bearing wear in auxiliary systems, contributing to longer drivetrain longevity and reduced maintenance costs.

Material selection is paramount for transmission flanges operating under continuous stress. Our wG2210100035/1 component uses aerospace-grade alloy steel with superior fatigue strength properties. The micro-alloy composition provides enhanced resistance to torsional flexing, preventing hairline fractures that often develop at stress concentration points. Special attention was paid to the root radius design between teeth, minimizing crack initiation possibilities that commonly plague inferior aftermarket products.

Operational efficiency is dramatically improved by the precision-ground tooth geometry. Each tooth flank features optimized involute curvature that maintains constant velocity ratio during engagement, eliminating power fluctuations common with worn components. The 180-face configuration provides more contact points for load distribution, reducing surface pressure by nearly 40% compared to standard 144-tooth designs. This design innovation translates directly to lower operating temperatures and extended lubricant life in HOWO transmission systems.

Installation considerations include proper flange seating verification before final torque application. Ensure the mating surface is clean and free of burrs that could affect concentricity. When replacing with genuine wG2210100035/1 flange, apply manufacturer-recommended thread locker to fasteners in specified patterns and sequences. Critical preload values must be achieved for optimum clamping force distribution – under-torquing can cause fretting corrosion while over-torquing may deform the flange body. Always verify output shaft runout within 0.05mm tolerance after installation.

Performance benefits become especially apparent under full-load conditions. Heavy hauls and steep inclines demonstrate the wG2210100035/1’s ability to maintain gear mesh integrity without deflection. Commercial operators report smoother power delivery during gear shifts and significantly reduced gear whine in the 180-degree tooth-engagement configuration. This noise reduction not only indicates precision manufacturing but reduces driver fatigue during long hauls, contributing to safer operating conditions.

Durability testing shows this output flange withstands accelerated fatigue cycles beyond OEM requirements. Simulating ten years of heavy-duty operation, the wG2210100035/1 maintained tooth profile integrity with less than 5% wear volume compared to 15-20% in economy alternatives. Actual fleet data corroborates these findings, with service intervals extending beyond 500,000 kilometers in highway operations when paired with proper maintenance schedules and quality lubricants.

Proper maintenance protocols include visual inspection during every transmission service. Check for abnormal tooth contact patterns indicating misalignment and monitor for micro-pitting along the load-bearing flanks. The 180-face design features wear indicator marks between teeth grooves that simplify inspection without disassembly – when these marks disappear, flange replacement should be scheduled. Combine this with used oil analysis for comprehensive drivetrain health monitoring.

Selecting authentic components is critical for transmission reliability. The wG2210100035/1 output flange utilizes proprietary heat treatment processes unavailable to generic manufacturers. Each batch undergoes material traceability verification and coordinate-measuring machine (CMM) inspection of all critical dimensions. Every flange leaving production carries unique identification matching HOWO quality standards, providing full quality documentation upon request.

For optimal transmission performance in rugged operations, specify the original wG2210100035/1 output flange. This precision component represents over 70% fewer warranty claims compared to pattern parts when installed in HOWO trucks operating in mining, logging, and construction applications. As the final link in the power transmission chain, investing in this correctly specified output flange protects your entire drivetrain investment.