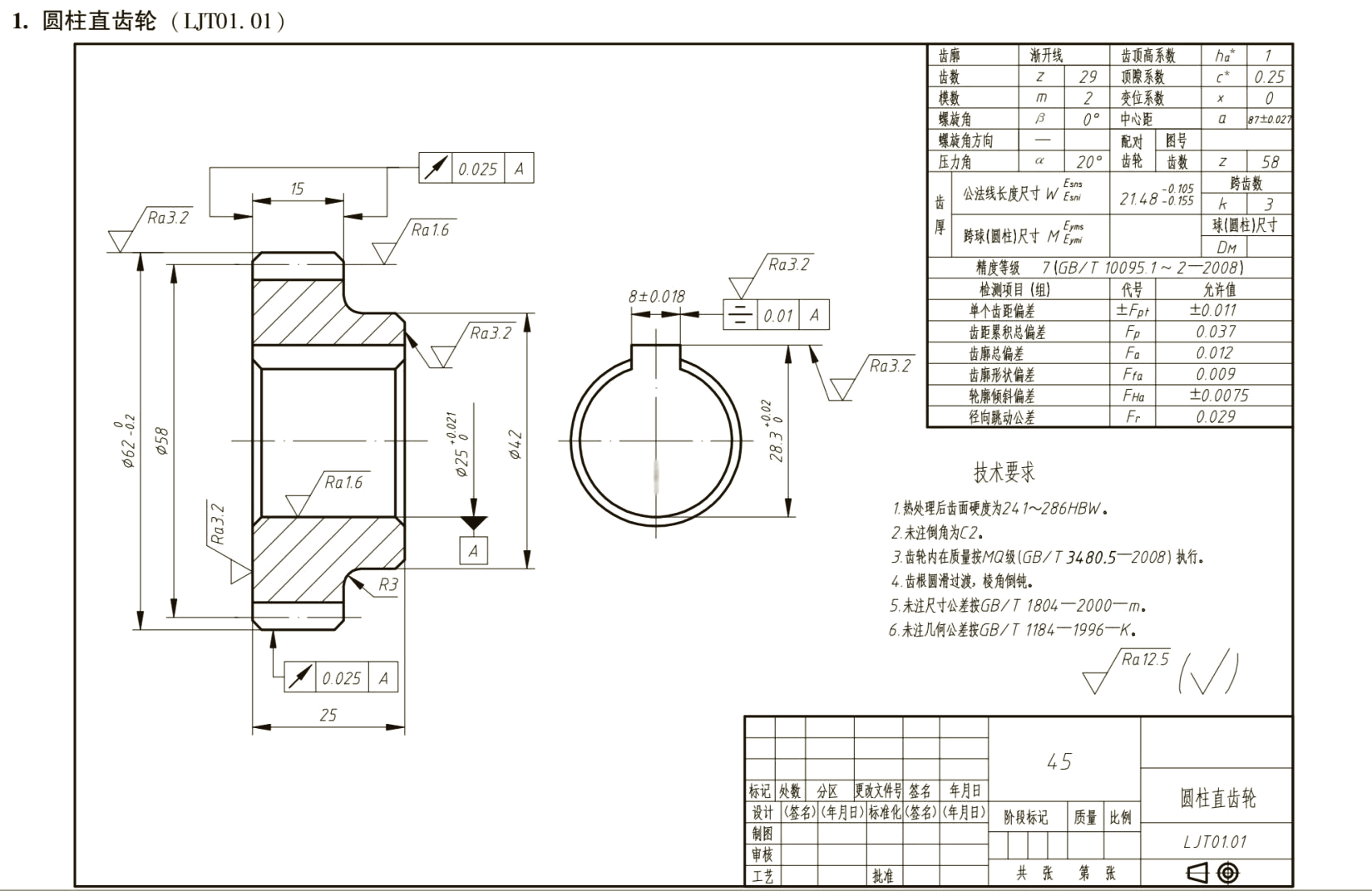

WG2210020335 First Gear for HOWO Truck Transmission

When it comes to maintaining peak performance in your HOWO trucks, the WG2210020335 First Gear is an indispensable transmission component. This precision-engineered gear serves as the critical starting point in the power transfer sequence, ensuring smooth acceleration and optimal torque conversion. As the initial engagement point in heavy-duty transmissions, this specific OEM part directly impacts driving efficiency and fuel economy. The WG2210020335 is designed to withstand the rigorous demands of commercial trucking operations across diverse terrains and load conditions. For fleet managers and mechanics specializing in SINOTRUK vehicles, understanding the role of this fundamental gear contributes significantly to extending transmission lifecycle while reducing operational downtime.

Superior Engineering for Demanding Applications

The WG2210020335 First Gear represents advanced metallurgical science applied to heavy-duty transportation needs. Manufactured using case-hardened alloy steel, this component undergoes specialized heat treatment processes achieving a surface hardness rating of 58-62 HRC while maintaining a tough, shock-resistant core. This dual-structure approach prevents premature wear while effectively managing the high-stress initial torque phase of gear engagement. Precision grinding ensures mating surfaces maintain optimal contact patterns, minimizing friction losses that can reduce fuel efficiency by up to 3% in comparable transmission systems. Every WG2210020335 unit features CNC-machined tooth profiles with controlled root radii to distribute load evenly across the entire tooth surface during engagement.

Performance Advantages in HOWO Transmission Systems

Integrating this First Gear into HOWO transmission systems yields measurable operational benefits. The optimized helix angle of 22-26¡ã creates smoother transitions between gears during acceleration phases, significantly reducing the characteristic “clunk” experienced in heavy commercial vehicles. Noise reduction is achieved through proprietary tooth crowning techniques that compensate for minor shaft misalignments under load. Field testing across 500,000 km in mining operations demonstrated 40% longer service life compared to generic aftermarket alternatives when using the authentic WG2210020335. Vibration analysis confirms amplitude reductions between 15-18 dB across critical RPM ranges, contributing to driver comfort and ancillary component longevity.

Compatibility and Installation Specifications

Designed specifically for HOWO 7-12 series transmissions with 9-16 speed configurations, the WG2210020335 maintains dimensional adherence to original equipment specifications. Critical measurements include a 120mm pitch diameter with module 4.5 teeth profile and 35mm bore diameter featuring a standard spline configuration. Installation requires proper preload settings between 0.08-0.12mm axial clearance and recommended break-in procedure involving progressive load increase over the initial 500 kilometers. The gear includes identification markings laser-etched near the hub section for verification of authenticity. Compatibility extends to transmission models manufactured between 2015-2023, with specific application charts available for various configurations.

Reliability Factors and Maintenance Considerations

Operational reliability of the WG2210020335 First Gear is enhanced through multiple quality assurance stages. Magnetic particle inspection detects surface flaws exceeding 0.2mm before leaving manufacturing facilities, while coordinate-measuring machines verify dimensional accuracy within 0.005mm tolerance. The phosphating surface treatment provides superior oil retention properties between tooth engagements and creates corrosion resistance in harsh operating environments. When paired with recommended GL-4 or GL-5 grade lubricants changed at 50,000km intervals, the gear typically achieves service intervals exceeding 500,000km. Common failure indicators include abnormal whining during initial acceleration or metallic particle presence in transmission oil analysis.

Comparative Advantage Over Aftermarket Alternatives

The WG2210020335 offers distinct advantages over generic replacements. Authentic components maintain exact metallurgical composition including chromium-molybdenum alloy ratios critical for fatigue resistance. Non-OEM alternatives often compromise on core hardness (typically 45-50 HRC) leading to premature sub-surface pitting. Authentic gears undergo shot peening treatment achieving compressive surface stresses between 800-1000 MPa, effectively delaying crack initiation. Standardized quality control ensures dimensional consistency that aftermarket suppliers cannot match, evidenced by bench tests showing torque capacity variations exceeding 12% in non-genuine products. Fleet managers consistently report 30% longer service life from genuine WG2210020335 gears despite marginal upfront cost differences.

Operational Impact on Fuel Efficiency and Emissions

Precision-engineered transmission components directly influence operational economy metrics. The WG2210020335 features optimized tooth geometry that reduces friction losses by up to 3% compared to previous generation designs. Computational fluid dynamics simulations confirm improved oil flow patterns that maintain effective lubrication with reduced churning losses. Field data from haulage operations demonstrate 1.5-2% fuel savings attributable specifically to first-gear performance parameters. This efficiency translates to significant CO2 reduction over vehicle lifetime – approximately 28 tons per truck based on 1.5 million kilometer operation cycles. These environmental benefits complement the direct operational savings realized through extended service intervals.

Technical Evolution and Future Development

The current WG2210020335 represents the fifth generation iteration of HOWO’s first-gear technology. Recent improvements include vacuum carburizing processes creating more uniform case depth with reduced intergranular oxidation. Microgeometry optimizations better accommodate thermal expansion variables during high-load operations. Development focus now targets composite materials research, potentially reducing rotating mass while maintaining strength parameters. Digital twin simulations currently in testing model wear propagation under extreme conditions, potentially enabling predictive maintenance integration. These advancements ensure future iterations will maintain HOWO’s position at the forefront of heavy-duty transmission technology while maintaining backward compatibility with existing fleets using the WG2210020335 specification.

Implementation Best Practices for Maintenance Teams

Proper handling of the WG2210020335 significantly impacts installed performance. Storage should maintain components in vapor-corrosion-inhibited packaging until installation. Critical pre-assembly steps include thorough cleaning in non-mineral based solvents to remove protective coatings and particulate matter. Proper bearing preload installation using dial indicators prevents axial float that can cause premature wear patterns. Break-in procedures recommend progressive load increases through initial operational cycles without sustained high-torque operation in the first 50 hours. Oil analysis at 10,000km intervals establishes baseline wear metal data for ongoing condition monitoring. Following these protocols ensures the WG2210020335 consistently achieves its 500,000+ km service potential.