WG2210020156 First Gear for HOWO Truck Transmission

The WG2210020156 First Gear is an essential transmission component specifically engineered for HOWO heavy-duty trucks. As the primary torque transfer point in the transmission system, this precision-crafted gear ensures smooth power delivery from the engine to the drivetrain. Manufactured to exacting HOWO specifications, WG2210020156 provides the critical first stage of gear reduction that enables your truck to efficiently manage heavy loads across diverse driving conditions. Unlike generic transmission parts, this OEM-specific component integrates perfectly with HOWO’s proprietary transmission architecture to maintain optimal performance.

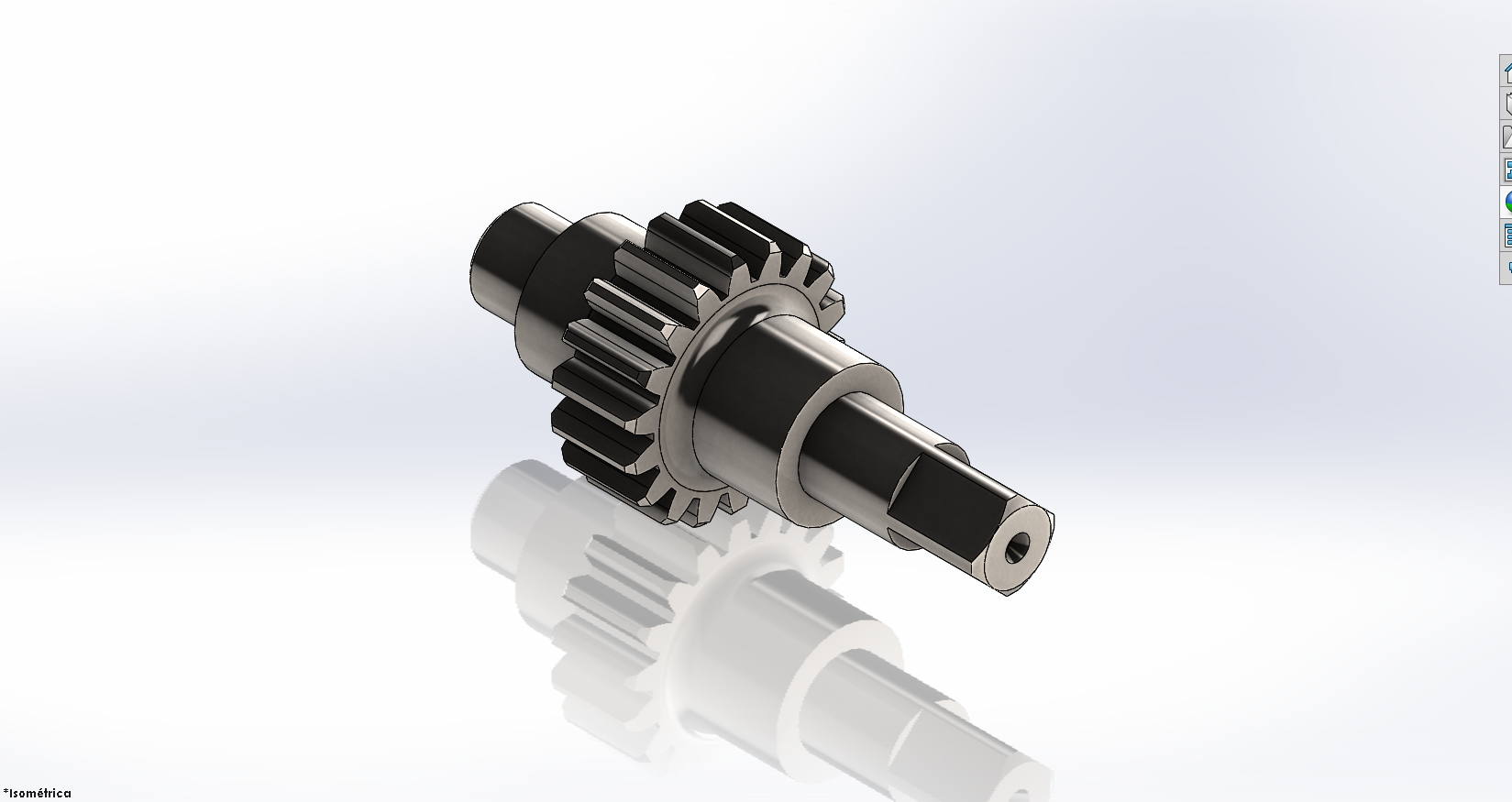

Designed as a direct replacement for worn or damaged components, WG2210020156 restores factory-grade functionality to your HOWO truck’s transmission system. Its helical tooth geometry reduces noise and vibration while distributing operational stress evenly across the gear surface. Each WG2210020156 first gear undergoes rigorous quality control to ensure precise dimensional accuracy and metallurgical integrity. The unique heat treatment process applied to this part creates an optimal balance between surface hardness for wear resistance and core toughness to withstand high-torque demands. This specific attention to material science extends the service life significantly compared to aftermarket alternatives.

Installation of the WG2210020156 is streamlined for professional technicians familiar with HOWO transmission systems. The gear’s design incorporates reference markings that facilitate correct alignment during assembly, preventing costly misalignment issues. When replacing your first gear, always verify compatibility using the WG2210020156 identification number stamped directly on the component. This alpha-numeric code guarantees authenticity and protects against counterfeit parts that may compromise your transmission’s reliability. Maintaining this critical interface component in optimal condition prevents collateral damage to synchronizers and bearings.

Operational benefits of using genuine WG2210020156 extend beyond basic functionality. This component optimizes fuel efficiency by minimizing power loss during torque transfer through its precision-ground tooth profile. The specialized surface finish reduces friction between meshing components, which translates to lower operating temperatures in the transmission housing. For fleet managers maintaining multiple HOWO trucks, standardizing on WG2210020156 ensures parts interchangeability and simplifies inventory management. The gear’s robust construction handles frequent stop-start cycles common in urban delivery operations and sustains performance through extended highway hauling applications.

Environmental resilience is engineered into WG2210020156’s core design. Special alloy compositions resist micropitting and surface degradation in extreme temperature variations from arctic cold to desert heat. Protective coatings on the gear teeth create a barrier against moisture-induced corrosion during seasonal transitions. These material innovations contribute to reduced maintenance frequency and operational downtime. When sourced through authorized channels, WG2210020156 comes with traceable documentation verifying its manufacturing origin and compliance with international quality standards.

Transportation professionals recognize the WG2210020156 as a mission-critical component that directly influences powertrain longevity. Its failure typically manifests as excessive gear whine, engagement difficulties, or metal contamination in transmission fluid. Proactive replacement at recommended intervals prevents catastrophic transmission damage and avoids secondary repair costs. Genuine WG2210020156 parts integrate seamlessly with factory control systems, ensuring accurate sensor readings and proper operation of computerized shifting mechanisms. This interoperability is particularly crucial for modern HOWO models equipped with automated manual transmissions.

Warehousing and logistical considerations for WG2210020156 prioritize part preservation. Each unit ships in custom foam-insulated packaging that cradles the gear teeth to prevent shipping damage. Desiccant pouches inside the packaging control humidity during storage and transport. These protective measures maintain the pristine surface condition necessary for perfect meshing with other transmission components. Batch and lot codes on both the part and packaging enable precise tracing throughout the distribution chain.

The economic impact of selecting WG2210020156 versus non-certified components becomes apparent in total cost analysis. While alternatives may present lower initial costs, their accelerated wear patterns lead to more frequent replacements and associated labor expenses. This authentic first gear delivers sustained performance through scheduled maintenance cycles, reducing long-term operating expenditures. Its extended service interval minimizes vehicle downtime, a crucial factor for commercial operators calculating revenue-per-mile metrics. Fleet managers consistently report fewer transmission-related breakdowns when standardizing on verifiable WG2210020156 components.

Application-specific testing protocols validate WG2210020156’s performance under simulated conditions mirroring real-world truck operations. Engineers subject samples to rotational force equivalents exceeding factory specifications to ensure structural redundancy. Accelerated lifecycle testing simulates hundreds of thousands of gear engagements without degradation. These validation procedures guarantee that each WG2210020156 meets HOWO’s durability standards before shipment. When properly installed using manufacturer-recommended procedures, this part consistently achieves its rated service life in diverse operational environments.

Specialized installation tooling facilitates proper fitting of WG2210020156 in professional service facilities. Dedicated bearing pullers and presses avoid improper seating that could cause premature failure. Torque sequence protocols specific to this gear prevent uneven load distribution during assembly. These specialized installation requirements underscore why professional service centers insist on using verified WG2210020156 components rather than generic substitutes. Technicians certified in HOWO transmissions receive specific training on the unique installation requirements of this critical powertrain element.

Environmental compliance is integral to WG2210020156 manufacturing processes. Production facilities utilize closed-loop coolant systems that recycle machining fluids and minimize waste. The metal alloys employed meet international standards restricting hazardous substances. Even the machining chips generated during production undergo reclamation and recycling. This environmental consciousness extends to the component’s operational efficiency – by minimizing friction losses, WG2210020156 contributes to reduced CO2 emissions throughout its service life.

Diagnostic protocols for identifying failing WG2210020156 components include specific acoustic analysis techniques. Distinctive high-frequency harmonics emerge when gear tooth profiles begin deteriorating, detectable before visible damage appears. Vibration spectrum analysis identifies imbalance issues related to gear wear. Technicians specifically trained on HOWO transmission systems recognize these auditory and tactile indicators during routine maintenance checks. Early detection allows planned replacement during scheduled service visits, avoiding catastrophic failures that strand vehicles during operations.

Inventory management systems categorize WG2210020156 with cross-references to all compatible HOWO transmission models. Electronic parts catalogs include detailed exploded diagrams showing the exact positioning within the gear train. Warehouse retrieval systems utilize the distinct WG2210020156 identification for rapid picking operations. Automated inventory tracking systems monitor regional demand patterns to maintain optimal stock levels across distribution networks. This sophisticated logistical support ensures timely availability for critical transmission repairs nationwide.

Global sourcing of WG2210020156 raw materials follows certified supply chains that maintain metallurgical consistency. Each alloy batch undergoes spectroscopy verification to confirm chemical composition before machining. Forging billets receive ultrasonic inspection to eliminate material imperfections. These material verification steps prevent fatigue failures that could result from metallurgical inconsistencies. The stringent quality gates ensure every gear bearing WG2210020156 identification performs reliably throughout its design life cycle.

Aftermarket support for WG2210020156 includes technical bulletins detailing installation best practices and torque specifications. Dedicated application engineers address specialized operational challenges in extreme environments like desert mining or arctic logistics. Online repositories maintain current documentation revisions accessible to service technicians worldwide. This technical infrastructure supports proper utilization and maximizes the performance potential in various operating scenarios.

Performance optimization begins with proper gear lubrication specific to WG2210020156 requirements. Manufacturer-recommended fluids contain specialized friction modifiers that extend surface finish integrity. These lubricants interact specifically with the gear’s metallurgical composition to prevent micropitting during boundary lubrication conditions common during cold starts. Always consult technical resources for the approved lubricant viscosity grade before servicing HOWO transmissions using WG2210020156.