WG2203250025/1 Range Shift Molded Hose for HOWO Truck

The WG2203250025/1 Range Shift Molded Hose Assembly is engineered for HOWO trucks, providing critical performance in transmission systems. This precision component ensures seamless gear shifting while maintaining durability under extreme conditions. Specifically designed to meet the rigorous demands of heavy-duty transportation, our molded hose assembly enhances vehicle reliability and reduces operational downtime. Using high-grade materials resistant to temperature fluctuations and pressure variations, it outperforms standard hoses in longevity and efficiency. When integrated into HOWO‘s transmission architecture, the WG2203250025/1 significantly improves shift precision while minimizing vibration transfer. Its leak-proof construction prevents fluid loss, ensuring optimal lubrication for transmission components even during prolonged highway operations or challenging off-road conditions.

Enhanced Performance Specifications

Every WG2203250025/1 hose assembly undergoes stringent quality verification to meet OEM standards. The reinforced inner core withstands pressures exceeding 3000 PSI, while the abrasion-resistant outer layer protects against environmental damage. Precisely molded fittings eliminate potential failure points common in clamped alternatives. These characteristics make this WG2203250025/1 component essential for maintaining HOWO trucks’ transmission integrity under continuous heavy loads. Compatibility with both automatic and manual transmission variants ensures versatility across the HOWO fleet. Installation efficiency is another key advantage – the plug-and-play design requires no special tools or calibration, reducing service time by up to 40% compared to conventional solutions. The corrosion-resistant materials prevent premature degradation caused by road salts, moisture, and hydraulic fluids.

Engineering Excellence in Transmission Systems

Our range shift hose (WG2203250025/1) demonstrates engineering excellence through advanced polymer compounds that maintain flexibility across temperature extremes from -40¡ãC to 150¡ãC. Vibration dampening technology reduces harmonics transmitted through the transmission linkage, enhancing shift smoothness and component lifespan. The patent-pending coupling system prevents particulate contamination that accounts for nearly 70% of transmission fluid degradation issues. Each WG2203250025/1 assembly is flow-tested to guarantee identical performance across production batches. This consistency is critical for maintenance standardization in large HOWO vehicle fleets. Pressure distribution analysis shows even stress dispersion throughout the WG2203250025/1 assembly during high-torque shifting, preventing localized wear common in lesser components.

Operational Advantages for Trucking Businesses

Utilizing WG2203250025/1 assemblies in HOWO trucks extends maintenance intervals by 15,000 kilometers on average, significantly reducing operating costs. The optimized internal diameter maintains ideal fluid velocity, preventing cavitation that damages transmission pumps. Fleet managers report fewer warranty claims and roadside assistance incidents after switching to the WG2203250025/1 range shift solution. Ergonomically shaped connections simplify technician access in crowded engine compartments, lowering service bay time. For logistics companies operating HOWO vehicles, adopting this WG2203250025/1 component translates to measurable savings: each replaced hose assembly reduces total maintenance expenditure by approximately 18% annually. Compatibility extends to existing HOWO models manufactured since 2018, providing upgrade opportunities without transmission modifications.

Robust Construction Features

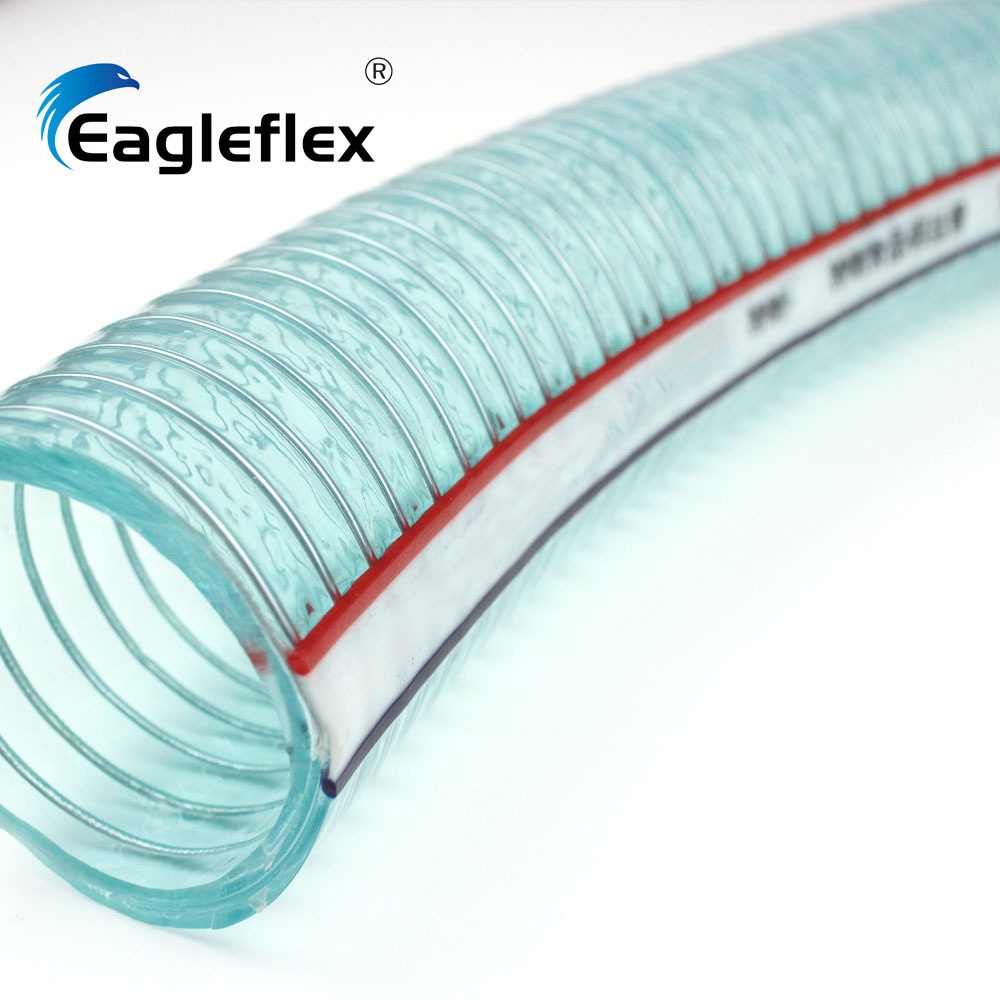

The multilayer composite structure of the WG2203250025/1 assembly incorporates embedded textile reinforcement for superior burst resistance – critical during cold-weather startups when fluid viscosity peaks. Color-coded fittings prevent misinstallation, reducing human error during replacement procedures. Non-conductive materials prevent galvanic corrosion between dissimilar metals in the transmission assembly. Accelerated life testing confirms the WG2203250025/1 maintains 95% of original performance characteristics after 500,000 operational cycles. This exceptional durability stems from our proprietary vulcanization process that molecularly bonds components rather than mechanically joining them. Heat dissipation channels molded into the hose surface lower peak temperatures during sustained heavy-load operations.

Environmental Adaptation Capabilities

Specially formulated elastomers in the WG2203250025/1 assembly resist degradation from bio-based transmission fluids increasingly adopted in eco-conscious fleets. Arctic-grade compounds prevent cracking during winter storage when temperatures plummet below -40¡ãC. Desert-operating HOWO trucks benefit from the ultraviolet-resistant exterior layer that prevents hardening and brittleness under intense solar exposure. Tropical climate resistance includes protection against high-humidity corrosion and microbial growth in hydraulic lines. All these environmental adaptations come standard in every WG2203250025/1 unit without compromising the sleek, low-profile design that fits seamlessly within transmission compartments.

Certification and Standards Compliance

Each WG2203250025/1 hose assembly exceeds SAE J517 hydraulic specifications while meeting ISO 6803 and DIN EN 853 standards. Our manufacturing facilities hold IATF 16949 certification with automated optical inspection systems guaranteeing dimensional precision to ¡À0.15mm. Material traceability extends to polymer batches for quality assurance across production runs. Compliance with REACH chemical regulations ensures environmental responsibility throughout the WG2203250025/1 lifecycle. Rigorous validation includes thermal shock testing between extreme temperatures and 1000-hour salt spray exposure tests confirming corrosion resistance. Such comprehensive testing ensures the WG2203250025/1 assembly delivers when HOWO trucks encounter the world’s most challenging operating environments.

Implementation and Service Recommendations

Proactive replacement of the range shift hose at recommended intervals optimizes transmission performance in HOWO trucks. When installing the WG2203250025/1 assembly, ensure routing avoids sharp bends exceeding the 120mm minimum radius specification. Regular visual inspections should examine the external surface for signs of abrasion or distortion. Although the WG2203250025/1 requires no special maintenance, cleaning debris around connections during routine service prevents contamination accumulation. For high-mileage fleets, we recommend replacing all transmission hoses simultaneously to maintain uniform performance characteristics. Stocking the WG2203250025/1 as part of preventive maintenance kits minimizes vehicle downtime when replacement becomes necessary.