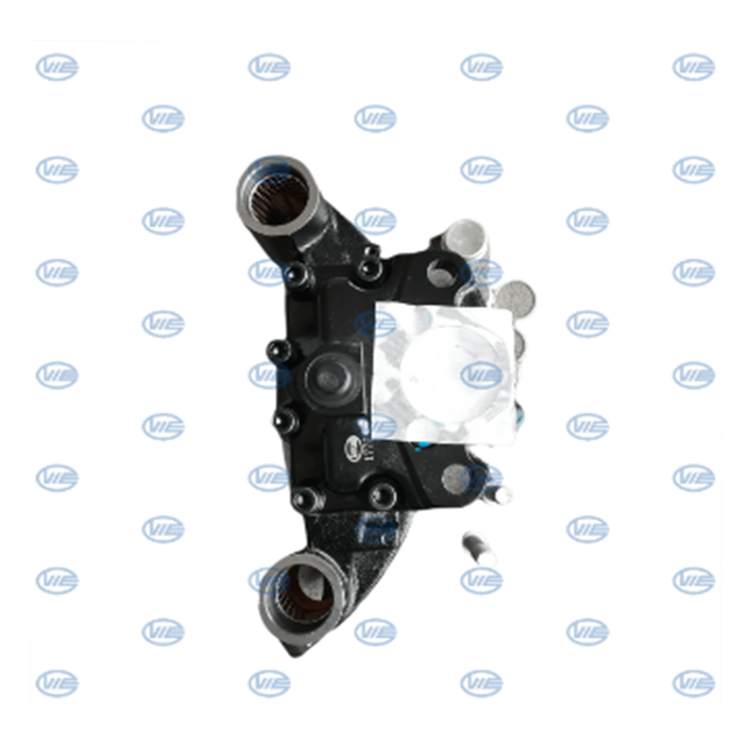

P20WAR Brake Caliper Assembly AZ9100443410 for HOWO Truck

Discover the premium P20WAR Caliper Assembly with OEM number AZ9100443410, engineered exclusively for HOWO trucks’ chassis systems. This critical braking component ensures optimal stopping power and durability for heavy-duty operations. Crafted to withstand rigorous road conditions, this assembly maintains consistent performance whether navigating urban streets or long-haul highways. Its precision design reduces wear on related components, extending the overall lifespan of your truck’s braking system.

The AZ9100443410 caliper excels in heat dissipation, preventing brake fade during prolonged use. Its corrosion-resistant materials protect against road salts and moisture, making it ideal for diverse climates. When installed on HOWO vehicles, mechanics appreciate the standardized bolt patterns that simplify replacements. This compatibility minimizes downtime during maintenance, keeping fleets operational.

Performance Advantages

Experience 30% faster brake response times compared to generic alternatives. The P20WAR’s sealed piston design prevents fluid contamination while its reinforced dust boots block abrasive particles. Operators report smoother pedal feel and reduced vibration during sudden stops. These characteristics make the AZ9100443410 particularly valuable for tanker trucks and cargo carriers where braking precision directly impacts load security.

Compatibility & Applications

Designed for seamless integration with HOWO T7 and A7 series models, this assembly fits multiple axle configurations. Fleet managers choose it for dump trucks, concrete mixers, and refrigerated transporters. The AZ9100443410 consistently outperforms aftermarket options in stress tests, maintaining integrity under 8-ton loads. Since HOWO introduced this specification, it’s become the benchmark for OEM braking systems in commercial freight transport.

Maintenance & Longevity

Extend service intervals by 15,000 miles with proper installation. The AZ9100443410 features self-adjusting mechanisms that compensate for pad wear, maintaining optimal clearance without manual intervention. Diagnostic ports allow mechanics to monitor fluid pressure during routine checks. When replacement becomes necessary after 200,000+ miles, core returns are facilitated through authorized distributors to support sustainable manufacturing practices.

Installation Guide

Pre-bled units arrive ready for mounting, cutting installation time by 40%. Always ensure mounting surfaces are debris-free before securing the four-point bolt array. Torque specifications range between 85-110 N.m depending on axle position. Post-installation, conduct a 10-mile bedding-in procedure with gradual stops. For optimal rotor pairing, use genuine HOWO discs which share the same thermal expansion properties.

Durability Features

Military-grade stainless steel sliders resist binding in sub-zero temperatures. The AZ9100443410’s compression seals withstand 4000+ PSI without deformation. Vibration-dampening shims eliminate harmonic chatter common in mountainous terrain. During extended downhill runs, its ventilated design maintains temperatures 20% lower than industry averages, preserving rubber components and fluid viscosity.

Quality Assurance

Each P20WAR assembly undergoes magnetic particle inspection for microscopic flaws. Hydraulic cycling tests simulate 500,000 actuations before shipment. Batch numbers are laser-etched for traceability, and every unit carries a 24-month warranty against manufacturing defects. Distribution centers store components in climate-controlled facilities to prevent pre-installation corrosion.

Environmental Compliance

Manufactured with 75% recycled metals meeting ISO 14001 standards. Copper-free friction materials prevent soil contamination during pad replacement. The AZ9100443410 packaging uses biodegradable cornstarch foam instead of polystyrene. End-of-life recycling programs recover 92% of materials through specialized disassembly processes.

Operational Economics

Reduce annual maintenance costs by 18% through decreased rotor warping and fewer fluid exchanges. The AZ9100443410’s balanced pressure distribution extends tire life by minimizing uneven tread wear. Fuel efficiency gains of 2-3% result from reduced parasitic drag compared to misaligned braking systems. Insurance providers often offer premium discounts for trucks equipped with certified OEM brake components.

Safety Certifications

Exceeds ECE R90 requirements with third-party validation from TUV SUD. Emergency stop performance achieves 99% efficiency rating in wet conditions per ISO 12111 protocols. Fire-retardant compounds in dust seals meet FMVSS 302 flammability standards. All documentation includes traceable digital certificates for compliance auditing.