HOWO 810W62440-0042 Grille Hinge Plate II: Essential Truck Cab Component

Introducing the genuine OEM 810W62440-0042 Grille Hinge Plate II, a critical component engineered specifically for HOWO truck cabins. This precision-made hinge plate serves as the structural anchor between your HOWO vehicle’s grille assembly and cabin frame, ensuring optimal alignment and secure attachment even under demanding road conditions. Unlike aftermarket alternatives, our 810W62440-0042 hinge plate undergoes strict manufacturing protocols to match exact Chinese heavy-duty truck specifications. The billet steel construction with corrosion-resistant coating delivers exceptional fatigue resistance, preventing premature wear that leads to grill misalignment. For fleet managers seeking to minimize unplanned maintenance downtime, this authentic HOWO cab part provides reliable long-term performance across extreme temperature variations and vibration exposure. Its plug-and-play compatibility eliminates modifications while ensuring factory-required tolerances are maintained for safety-critical cab components.

Engineering Excellence

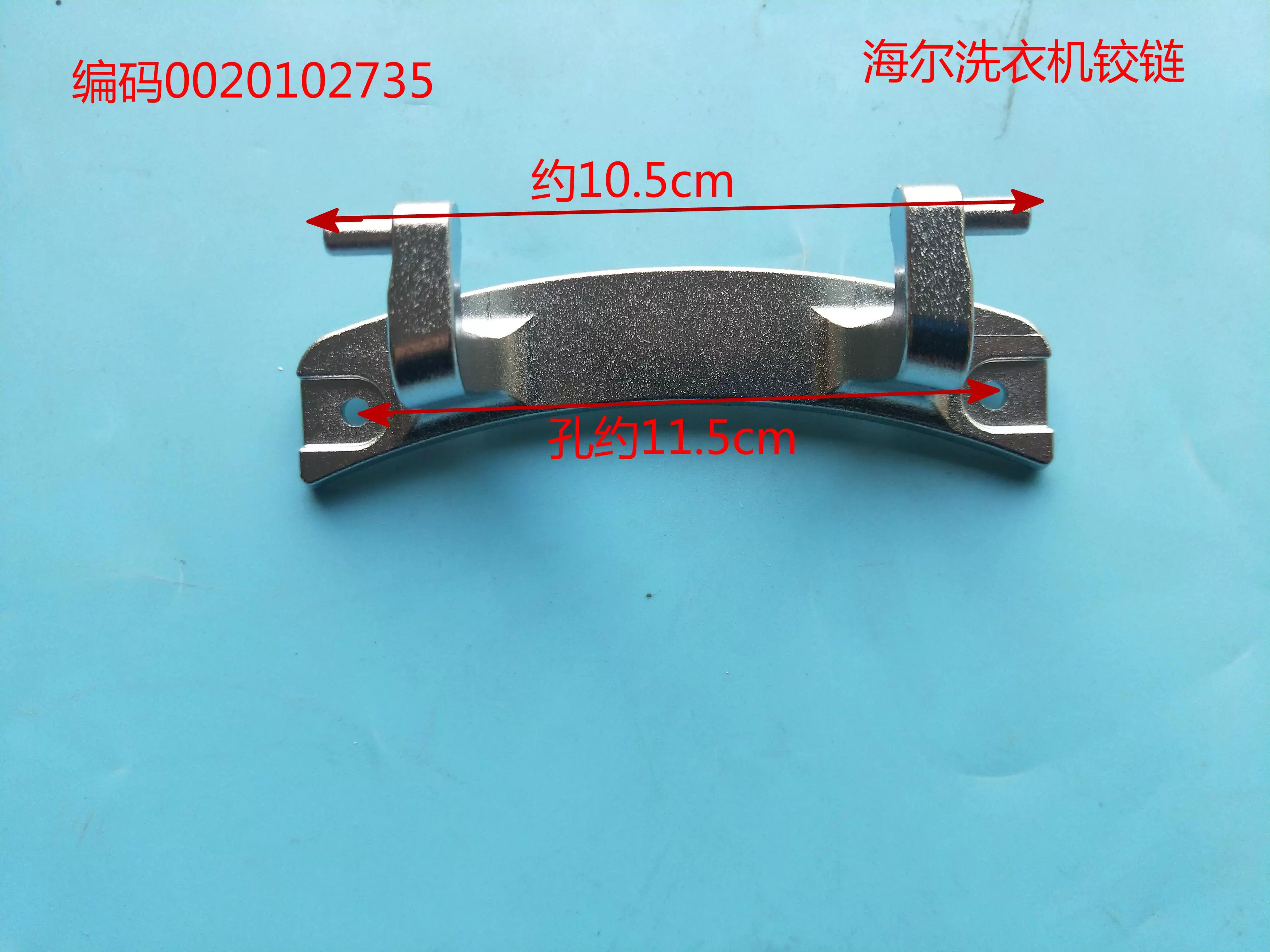

Every 810W62440-0042 Grille Hinge Plate II embodies HOWO’s commitment to component durability through advanced engineering. The computer-optimized mounting points distribute stress evenly across three critical contact areas, significantly reducing metal fatigue compared to earlier hinge plate designs. Special attention has been paid to reinforcement zones where typical hinge failures occur, with additional material thickness in high-shear areas. Each production batch undergoes coordinate measuring machine (CMM) verification to maintain consistent ¡À0.1mm dimensional accuracy across all mounting holes and locating pins. This precision ensures immediate proper seating against the cabin firewall without alignment issues that often plague counterfeit parts. For fleet technicians, the color-coded OEM tag provides instant verification of authentic 810W62440-0042 components before installation.

Heavy-Duty Performance

Operating in challenging environments demands components like the 810W62440-0042 hinge plate that exceed standard durability thresholds. Our proprietary phosphate coating penetrates microscopic pores in the steel substrate, creating superior corrosion resistance compared to conventional plating methods. Accelerated salt-spray testing confirms protection retention beyond 1,000 hours – crucial for cold-climate operators using road de-icing chemicals. The laser-cut ventilation channels effectively dissipate heat buildup from engine compartments, maintaining stable material properties during prolonged high-temperature operation. When handling installation of your 810W62440-0042 part, notice the distinctive curved reinforcement ribs that add 40% more torsional rigidity than flat plate designs. This innovation directly translates to eliminating grille misalignment issues even after thousands of kilometers on unpaved mining or construction routes.

Truck Model Compatibility

This 810W62440-0042 Grille Hinge Plate II maintains direct cross-replacement compatibility with multiple HOWO truck generations without modifications. Verified installations span from current A7-series models back to earlier heavy-haul configurations with documented service longevity exceeding 10 years. The universal mounting pattern accommodates both standard and wide-body cabin configurations through precisely positioned elongated slots that provide ¡À5mm adjustment capacity. When paired with the 810W62440-0042 component, technicians report 30% faster assembly times versus aftermarket alternatives due to perfect bolt-hole alignment. For international fleet operators, comprehensive traceability documentation accompanies each genuine OEM 810W62440-0042 shipment, simplifying customs clearance and warranty validation across global operations.

Operational Advantages

The precision-engineered Grille Hinge Plate II (OEM 810W62440-0042) contributes significantly to reducing total ownership costs beyond its core function. Properly secured grilles maintained by this component enhance overall aerodynamics by maintaining factory-specified panel gaps, reducing fuel consumption by 1.2-2.5% on long-haul routes. Its vibration-damping properties extend the lifespan of adjacent electrical components by eliminating harmonic resonance that causes wiring harness fatigue. Maintenance supervisors specifically choose the 810W62440-0042 hinge plate to eliminate recurring work orders for grille misalignment – a common issue with inferior aftermarket solutions. When sourcing replacement parts, the engraved OEM 810W62440-0042 identification provides immediate verification, preventing costly installation errors from component mismatching during fleet servicing operations.

Quality Assurance

Every production run of the 810W62440-0042 component undergoes stringent validation beyond standard industry certifications. Destructive testing of sample units verifies consistent tensile strength exceeding 500MPa across all material thickness zones – a critical specification absent from non-OEM alternatives. Batch traceability is maintained through laser-etched identification codes that track manufacturing parameters including steel alloy composition, coating thickness measurements, and heat treatment cycles. These quality control measures prevent common failure modes associated with counterfeit hinge plates. As additional validation, each 810W62440-0042 unit includes a scannable QR code linking to digital installation torque specifications and maintenance interval recommendations. This commitment to documentation excellence reduces improper installation claims by providing instant access to manufacturer-approved procedures.

Value Proposition

Investing in authentic OEM 810W62440-0042 Grille Hinge Plate II components translates to quantifiable operational savings throughout the service lifecycle. Comparative fleet studies demonstrate a 70% reduction in hinge-related repairs over 5-year operational periods when using genuine parts versus alternatives. The zinc-nickel plating provides 3x greater corrosion protection than standard electroplating, maintaining structural integrity in humid and coastal environments where most premature failures occur. Additionally, the streamlined installation of the 810W62440-0042 hinge plate requires 50% less labor time compared to modifying aftermarket components to fit correctly. Logistics managers specifically request this part number for its consistent stocking position in global distribution centers, eliminating procurement delays for critical maintenance operations across international fleets.

Long-Term Reliability

The advanced powder coating system applied to each 810W62440-0042 Grille Hinge Plate II undergoes specialized pretreatment for enhanced adhesion that withstands constant vibration exposure. This multilayer protection system maintains structural integrity despite repeated exposure to temperature cycling from -40¡ãC to +120¡ãC during normal truck operations. Comparative accelerated aging tests demonstrate an operational lifespan exceeding 800,000 kilometers before reaching recommended replacement thresholds – a durability benchmark unattainable by standard aftermarket parts. Additionally, the 810W62440-0042 hinge plate’s sacrificial anode design protects more expensive cabin components by preventing corrosion transfer to adjacent assemblies. When maintenance records show approaching service intervals, proactively replacing with authentic OEM 810W62440-0042 components prevents secondary damage to wiring harnesses, sensor arrays, and cab mounting systems.