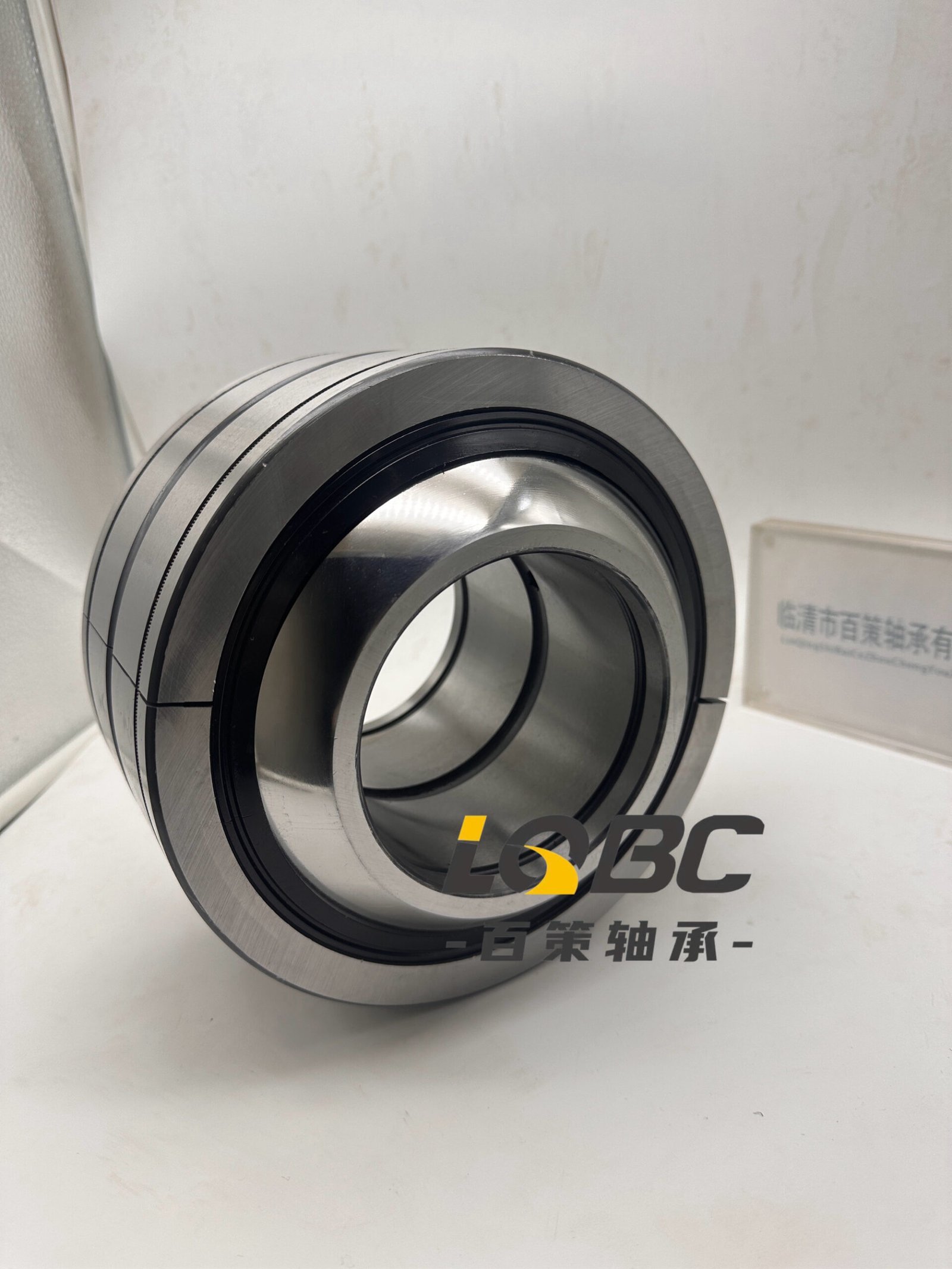

812W35701-0156 Rear Wheel Hub for HOWO Truck Drive Axle

The 812W35701-0156 Rear Wheel Hub is a critical component specially engineered for HOWO trucks’ drive axle systems. As the central connection point between the wheel and axle, this precision-machined hub ensures optimal power transfer from the drivetrain to the wheels. With part number 812W35701-0156 directly cast into its surface, this OEM-grade component guarantees perfect compatibility with HOWO truck models requiring durable drive axle solutions. Manufactured to exact specifications, it delivers reliable performance under heavy-load conditions while maintaining wheel alignment and rotational stability. The hub’s robust construction withstands extreme torsional forces encountered in commercial truck operations.

Precision Engineering for Heavy-Duty Performance

Precision-crafted for HOWO truck applications, the 812W35701-0156 rear wheel hub undergoes rigorous quality control at every manufacturing stage. The hub’s bearing surfaces receive special hardening treatments to resist wear patterns caused by continuous rotational stress. Critical dimensions and bolt circle patterns match original HOWO truck specifications precisely, ensuring direct bolt-on installation without modifications. This attention to engineering detail translates to extended service intervals and reduced maintenance costs for fleet operators.

Durability Features

Structural integrity defines the 812W35701-0156 hub, with its one-piece forged construction eliminating weak points found in cheaper alternatives. High-grade alloy composition provides optimal strength-to-weight ratio, resisting deformation under maximum load conditions. The wheel mounting flange features reinforced bolt bosses to prevent thread stripping, while precision-machined surfaces maintain proper bearing pre-load throughout the component’s lifecycle. Protective coatings on non-critical surfaces combat environmental corrosion in diverse operating climates.

Performance Optimization

Beyond basic function, the OEM 812W35701-0156 hub enhances overall drivetrain efficiency through minimized rotational mass and optimized thermal characteristics. Computer-balanced construction eliminates vibration at highway speeds, reducing stress on adjacent components. The hub’s internal oil pathways ensure consistent lubrication to wheel bearings, while precision-sealing surfaces prevent contamination from dirt or moisture. This design synergy between hub and bearing systems translates to measurable fuel efficiency gains during long-haul operations.

Application Specific Design

Unlike generic replacement parts, this wheel hub has configuration-specific features tailored for HOWO truck drive axles. The spline pattern corresponds exactly to axle shaft dimensions in designated HOWO models, eliminating power transfer slippage. Installation clearance parameters account for factory brake caliper positions and suspension geometry, preventing interference issues common with aftermarket alternatives. Each production batch undergoes application-specific validation testing before release.

Reliability in Extreme Conditions

The 812W35701-0156 hub consistently performs under punishing conditions that challenge inferior components. Thermal analysis during development ensures stable operation across temperature extremes from arctic cold to desert heat. Structural reinforcement in high-stress areas prevents fatigue cracks in mining and construction environments. Tested beyond standard durability requirements, the hub maintains integrity during emergency maneuvers and off-road excursions where failure isn’t an option.

Maintenance Advantages

Serviceability features engineered into the 812W35701-0156 design reduce maintenance time and expense. The hub includes integrated tool clearance for standard service equipment, along with visual wear indicators that simplify inspection routines. Precision manufacturing minimizes runout variation, resulting in extended seal life and reduced lubricant leakage. Replaceable wear components separate from the main hub body extend total lifecycle value while reducing replacement part costs.

Compatibility Assurance

Vehicle-specific fitment guaranteed by the 812W35701-0156 identifier provides installers confidence in compatibility with designated HOWO truck models. Every component produced carries laser-etched OEM identification matching factory specifications. Production utilizes the exact CAD data employed in HOWO manufacturing facilities, ensuring dimensionally perfect mating with adjacent assemblies including brake rotors, bearings, and axle assemblies.

Quality Validation Process

Before leaving the factory, each 812W35701-0156 hub undergoes material verification scans and coordinate-measuring machine inspection across 28 critical dimensions. Production sample components endure accelerated life testing that simulates 500,000 road miles of harsh conditions. Final quality certification includes rotational balance validation and torque yield testing on mounting hardware. This comprehensive validation process consistently delivers the durability that commercial truck operations demand.

Operational Economics

The true value of the 812W35701-0156 hub emerges through reduced total operating costs. Extended service intervals minimize vehicle downtime, while precision construction prevents collateral damage to expensive bearings and seals. Weight optimization reduces unsprung mass, improving both fuel efficiency and suspension component life. By eliminating premature failures and subsequent roadside repairs, the hub delivers quantifiable savings throughout its service life.

Logistical Support

Global availability of the 812W35701-0156 hub means fleet operations maintain operational continuity across multiple regions. Direct-from-manufacturer distribution eliminates compatibility uncertainty encountered with aftermarket alternatives. Comprehensive technical documentation provides installation specifications and maintenance procedures. Supply chain reliability ensures minimal downtime when scheduled maintenance coincides with operational demands.