SINOTRUK TRUCK ENGINE SPARE PARTS

SINOTRUK TRUCK ENGINE AND ENGINESPARE PARTS

In the mines, roads and farmlands of Zimbabwe, every roaring SINOTRUK engine is the cornerstone of efficient transportation. With decades of technical accumulation, China National Heavy Duty Truck (CNHTC) supplies original engine assemblies, core parts and maintenance kits directly to Zimbabwean market, and solves the pain points of local users with “super durability and extremely fast response service” – whether it’s the heavy-duty climbing in platinum mines, the long-distance running in cross-border logistics, or the rainy weather. Whether it is the heavy-duty climbing in platinum mines, long-distance running in cross-border logistics, or the erosion of the power system due to humidity and heat in the rainy season, SINOTRUK engines have always become the first choice of Zimbabwean customers for their “heart of power” with their stable output and ultra-long service life.

Zimbabwe's Hot-selling Engines and Accessories: Made for African Working Conditions

Engine Assembly

– Weichai WP10/WP12 series: optimized for high temperature, heavy load and low quality fuel in Africa, adapted to HOWO T7H, A7 and other main models, with maximum power up to 480 hp, torque of 2,200 N-m, and no overhaul mileage of more than 500,000 kilometers measured in the mining area.

– MAN TECHNOLOGY MC09 high-end model: with modular design and intelligent fuel saving system (EBP) that can reduce fuel consumption by 15%, it is especially suitable for long-distance mainline transportation of cross-border logistics fleet from Harare to Beitbridge.

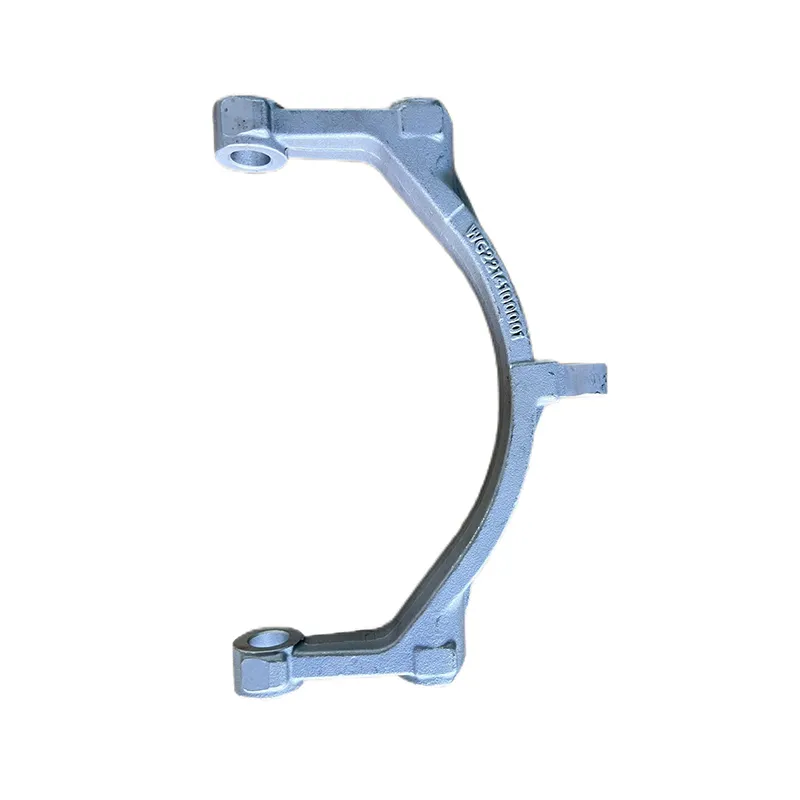

Core hot-selling accessories

– Common Rail Injector: customized for Zimbabwe low-sulphur diesel (sulphur content <500ppm), solving the problem of carbon blockage in the injector nozzles and improving fuel efficiency by 20%.

–Turbocharger assembly: high temperature resistant alloy blade design, adapting to the continuous high load operation in mining area, service life is 3 times longer than the sub-factory parts.

– Three-stage composite air filter: multi-layer filtration structure captures 99.9% of dust (e.g., PM10 concentration in Dawanwai mining area is more than 1000μg/m³), and protects the cylinder block from particle wear.

– Reinforced cylinder liner and piston ring: made of boron cast iron, the tensile strength is increased by 35%, which completely solves the cylinder pulling failure caused by overloading in mines.

– Intelligent ECU control module: Built-in African working condition data package, automatically adjusts fuel injection and air intake efficiency, suitable for plateau, high temperature and dusty environment.

Testimonials

What They Say's

The following is a review of Sinotruk’s hot-selling vehicle lines and accessories in the Zimbabwe market

Guardian of the whole process from Chinese factory to African construction site

Military-grade packaging

1. Precision parts protection

– Shock and moisture-proof sealing: turbocharger, ECU module and other precision parts are fixed by vacuum moisture-proof film + EPE foam customized molds, and humidity sensors are embedded in the outer box for real-time monitoring of the shipping environment.

– Anti-corrosion treatment: Cylinder block, crankshaft and other metal parts are sprayed with VCI vapor-phase anti-corrosion film, and wrapped with desiccant and anti-corrosion paper in multi-layer package to eliminate the risk of rust and corrosion caused by the rainy season shipping.

2. Engine assembly packaging

– All-steel frame fixation: the engine body is locked on the steel pallet by bolts, covered with rainproof canvas and PE wrapping film, and the corners are fitted with rubber bumper strips to withstand cross-border transportation bumps.

– Transparent Quality Inspection Window: A visualization window is opened on the side of the packing box, so that the serial number and appearance integrity of the engine can be checked without unpacking, which reduces customs clearance disputes in Zimbabwe.

Extremely Fast Response, Mission Accomplished

Efficient Transportation Network

1. Sea transportation main channel

– Full container special line: starting from Qingdao/Tianjin port, transshipment to Harare via Durban port of South Africa, the whole journey takes 25-30 days, 40-foot container can load 60 engines or 2,000 pieces of spare parts, the freight rate is as low as $2.1/kg.

– Consolidated container service: small and medium-sized orders can be shipped in consolidated containers, with a minimum order quantity of 500kg, and provide “door-to-door” customs clearance and tax payment services.

2. Air transportation emergency protection

– Emergency missing parts direct flight: Beijing/Guangzhou direct flight to Robert Mugabe International Airport in Harare, 3-5 days delivery, support lithium battery parts (such as ECU module) compliant transportation.

– Cost Transparency: A WP12 engine assembly (1200kg) costs about $6800 by air, suitable for emergency replacement needs in case of sudden failure in mines.