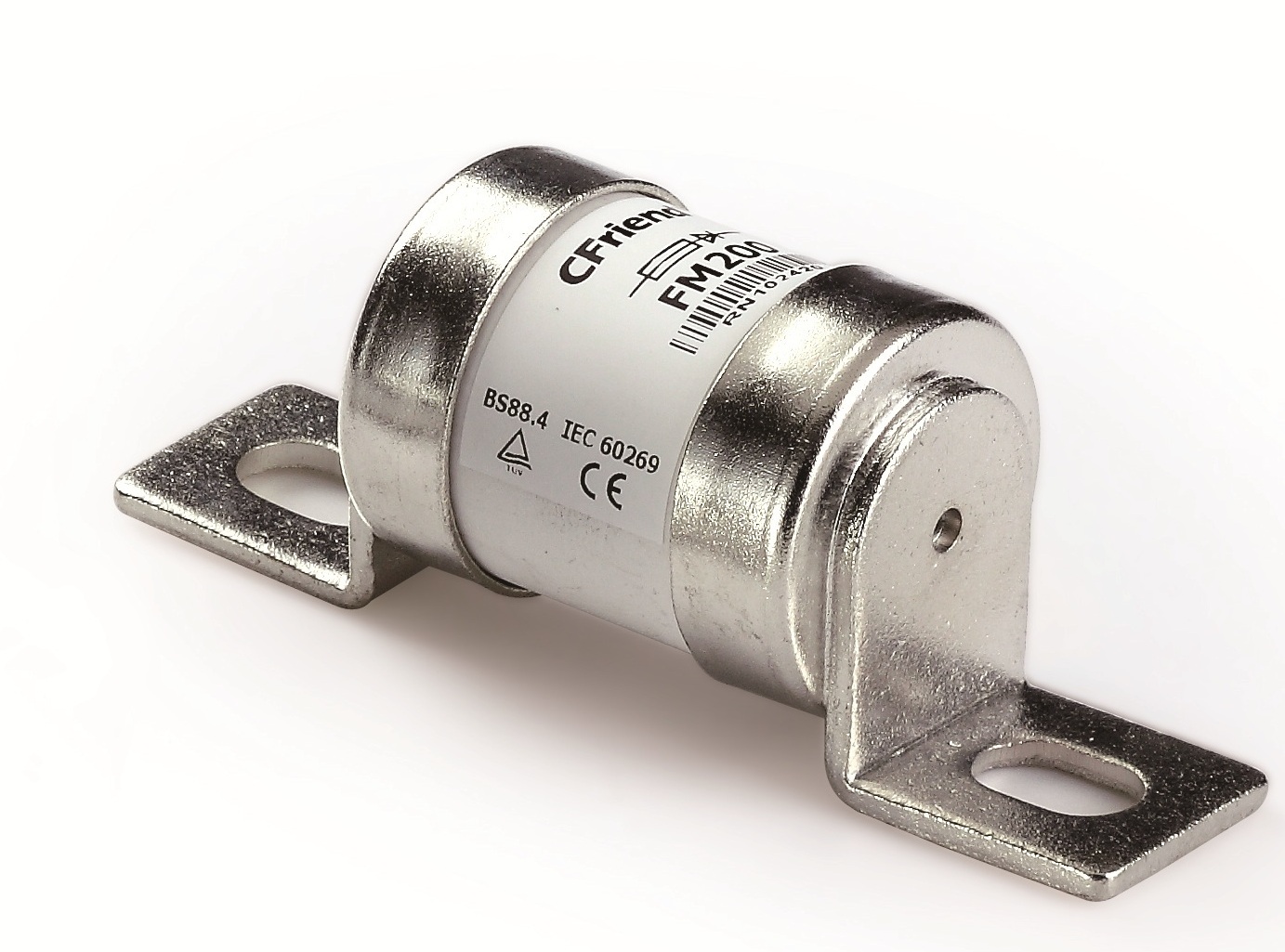

WG9716582301+002/1 7.5A Blade Fuse for HOWO Truck Electrical

This original WG9716582301+002/1 7.5A Blade Fuse is engineered specifically for HOWO trucks’ electrical systems, providing critical protection against circuit overloads in harsh operating environments. The precision-rated 7.5-amp capacity safeguards sensitive components throughout HOWO‘s cab electronics, lighting systems, and auxiliary equipment. Its compact blade design ensures quick installation and reliable performance under extreme temperature fluctuations and vibration conditions common in commercial truck operations. The fuse features color-coded identification and durable housing materials that resist corrosion while allowing visual inspection of the fusible element.

Superior Electrical Protection

Engineered for optimal circuit protection, this blade fuse interrupts electrical flow within milliseconds when current exceeds its 7.5A rating. This rapid response safeguards HOWO truck components from costly voltage spikes and thermal damage. The transparent housing allows immediate visual confirmation of fuse status during maintenance checks.

Truck operators benefit from the standardized micro-sized blade design that fits universally across HOWO fuse boxes from current and recent generations. The WG9716582301+002/1 component features industrial-grade brass terminals with tin plating to ensure minimal voltage drop and enhanced conductivity, even in high-humidity environments. This critical protection element maintains stability across temperature ranges from -40¡ãC to 100¡ãC.

Replacing this specific OEM component ensures electrical safety compliance across regions while preventing warranty issues that may arise from non-genuine alternatives. The WG9716582301+002/1 maintains precise calibration throughout service life with negligible performance degradation over time.

Reliability in Harsh Conditions

Heavy-duty trucks demand protection components engineered for extreme conditions. This blade fuse features vibration-resistant construction tested to withstand 30G impacts and frequency oscillations common in HOWO chassis. The polyamide housing resists automotive chemicals while preventing moisture ingress that could cause false triggering.

Each WG9716582301+002/1 unit incorporates sand-filled arc suppression technology to extinguish electrical arcs during overload events. This prevents secondary damage to adjacent circuits in densely packed fuse panels. Installation requires no tools thanks to the ergonomic pull tabs designed for gloved-hand operation during emergency roadside replacements.

The fuse’s UV-stabilized housing maintains clarity for status checks even after years of sun exposure through truck windows. All materials meet ROHS standards with lead-free construction supporting environmental regulations.

Application Specifics

This 7.5A blade fuse protects critical circuits in current-generation HOWO tractors and vocational trucks including lighting systems, telematics modules, and dashboard instrumentation. Positioned in secondary power distribution panels, it functions as the first line of defense for electronics with moderate current requirements.

WG9716582301+002/1 is cross-referenced to protect circuits ranging from trailer connector systems to entertainment consoles in sleeper cabs. Technicians should consult wiring diagrams since using incorrect amperage fuses may compromise electrical safety systems. Original factory-specified components maintain circuit protection profiles engineered by HOWO‘s electrical design teams.

Storage recommendations include keeping spare WG9716582301+002/1 fuses in their original packaging within temperature-controlled compartments. Most drivers keep at least two replacements in their emergency kit, given the crucial protection provided.

Performance Advantages

Operators report fewer electrical system failures when using genuine WG9716582301+002/1 components versus aftermarket alternatives. Each fuse undergoes multiple verification stages including automated resistance testing at different load profiles. Production includes optical inspection of terminal alignment and solder joints.

The low-profile design saves valuable space in congested junction boxes while allowing heat dissipation through the surrounding air. Voltage tolerance maintains stable conductivity even during cold starts when voltage fluctuations commonly occur. Consistent performance ensures sensitive electronics like driver-assist cameras and GPS trackers maintain reliable operation.

All genuine components incorporate traceability features including laser-etched serial numbers that support warranty claims. Distributors benefit from straightforward stock management with the standardized OEM numbering system across regions.

Compatibility Information

This blade fuse interchanges directly with factory-installed components across HOWO T7H, A7, and TX series trucks from 2018 onward. The compact WG9716582301+002/1 design fits fuse holders designed for standard micro2 blade profiles. Verification of compatibility should include checking circuit-specific requirements to ensure proper protection.

Fleet managers can transition to WG9716582301+002/1 replacements immediately without retrofitting or special tools. Using this original part rather than universal equivalents preserves factory-calibrated electrical response times that prevent cascading failures. All automotive-grade materials ensure compliance with commercial transport flammability standards.

The color blue denotes the 7.5A rating, allowing quick visual confirmation during installations. Replacement should occur after any triggering event since even minor overloads may compromise internal components.

Installation Guidelines

Replacing this fuse requires disconnecting battery connections to avoid accidental short circuits. Access the fuse box per the HOWO operator manual guidelines, typically located under the dashboard or behind cab-access panels. Use plastic-tipped extraction tools to prevent terminal damage during removal.

Confirm replacement is needed by checking for broken elements visible through the housing. Install the WG9716582301+002/1 unit with terminals aligned to the holder’s keyed slots until hearing an audible click. Avoid force during installation which may bend terminals. Post-replacement, verify proper function of associated circuits before continuing operations.

Electrical diagnostics should follow any recurring fuse failures since repeated triggering may indicate underlying wiring issues. HOWO service centers offer circuit diagnostics to identify root causes requiring attention beyond fuse replacement.