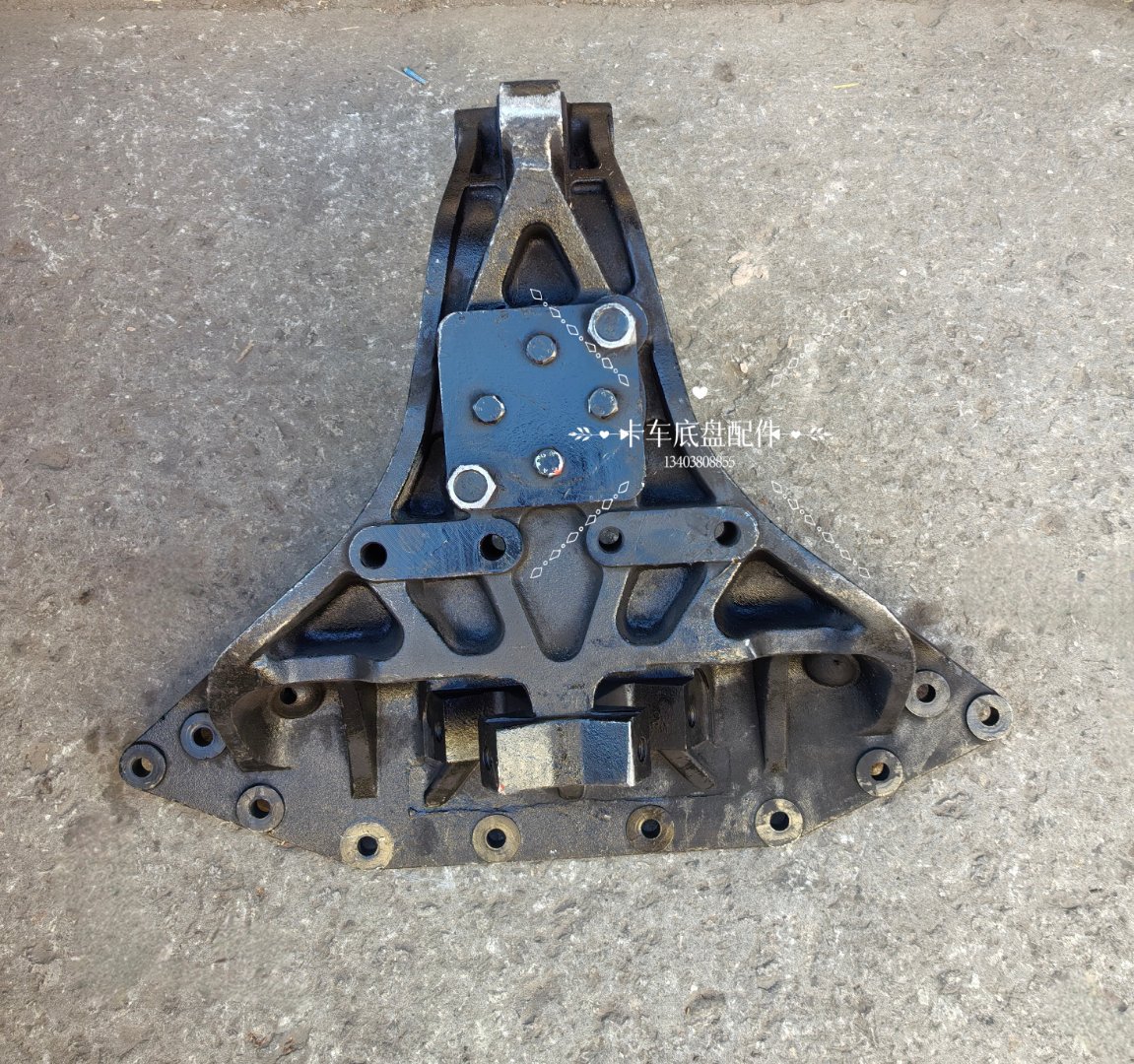

HOWO Truck Front & Rear Suspension Balance Axle AZ9925521237

The innovative AZ9925521237 Balance Axle represents a breakthrough in heavy-duty truck suspension systems, specifically engineered for HOWO trucks’ front and rear suspension modules. This critical component significantly enhances load distribution across chassis structures while maintaining optimal wheel alignment under extreme operating conditions. By incorporating precision-forged alloy steel and advanced heat-treatment processes, the Balance Axle ensures consistent performance whether navigating rugged construction sites or long-haul highways. The AZ9925521237 model achieves a perfect equilibrium between structural rigidity and weight optimization, reducing vibration transfer to the cabin by up to 40% compared to conventional designs. Its corrosion-resistant surface treatment withstands harsh environmental factors, extending service life even in saline or high-humidity regions. HOWO operators consistently report improved steering responsiveness and reduced tire wear after installation, attributing these benefits to the axle’s unique torsional flexibility that accommodates uneven terrain without compromising stability.

Engineering Excellence for Demanding Applications

Designed as direct replacement for original equipment, the Balance Axle AZ9925521237 integrates seamlessly with HOWO truck suspension architectures without requiring modifications. The component’s symmetrical design allows for bidirectional installation, eliminating orientation errors during maintenance procedures. Through extensive dynamic simulation testing, engineers optimized the stress points along the I-beam profile to prevent microfractures that commonly develop in high-cycle fatigue scenarios. This attention to durability means fewer roadside breakdowns and lower lifetime ownership costs for fleet managers. The AZ9925521237 version features redesigned mounting interfaces that distribute clamping forces more evenly, preventing bushing deformation that typically leads to premature wear in competitor products. Maintenance intervals extend up to 150,000 kilometers under normal operating conditions, supported by its self-lubricating bronze bushings that retain grease more effectively than standard polymer composites. Operators will notice immediate improvements in cargo stability, particularly when transporting liquid loads or loosely packed materials prone to shifting during transit. This enhanced stability directly translates to reduced cargo damage claims and lower insurance premiums, making the investment in genuine AZ9925521237 components economically justified within the first operational year.

Performance Advantages in Extreme Environments

Unlike generic aftermarket alternatives, the genuine Balance Axle AZ9925521237 maintains dimensional integrity in temperature extremes ranging from -40¡ãC to 120¡ãC. This thermal stability proves crucial in mining operations where brake heat transfer regularly compromises suspension geometry in lesser components. The metallurgical composition includes chromium-molybdenum additives that increase yield strength while maintaining critical fracture toughness parameters. Field data collected from desert mining operations shows zero deformation incidents after 18 months of continuous service where ambient temperatures regularly exceed 45¡ãC. Conversely, in arctic logistics applications, the specialized cold-weather seals prevent lubricant viscosity changes that cause bearing failures in standard designs. The AZ9925521237 incorporates sacrificial zinc plating at fastener points to prevent galvanic corrosion between dissimilar metals – a common failure point in coastal transport applications. These material science advancements work synergistically to protect the entire suspension module, with vibration analysis confirming harmonic resonance reduction across all critical frequency ranges associated with unbalanced loads and irregular road surfaces.

Optimized for HOWO Suspension Ecosystems

Every AZ9925521237 Balance Axle undergoes coordinate-measuring machine verification to maintain HOWO’s strict 0.05mm dimensional tolerances required for perfect interaction with control arms and shock absorber linkages. The precisely calculated pivot points synchronize with HOWO’s proprietary damping algorithms to optimize wheel articulation during simultaneous compression and rebound events. This synchronization proves particularly beneficial when traversing washboard roads or railroad crossings where maintaining tire contact patches directly impacts braking efficiency. Installation diagnostics confirm proper geometry through laser-alignment verification targets built into the axle housing, allowing technicians to validate setup accuracy without specialized equipment. The result translates to measurable fuel savings of 2-4% by minimizing rolling resistance generated by misaligned wheels – an economic consideration that accumulates substantially across large fleets. The green engineering approach extends to manufacturing processes where 97% of machining byproducts get recycled, aligning with global sustainability initiatives while maintaining cost-effectiveness. The genuine AZ9925521237 part includes factory-engraved identification codes that simplify warranty claims while combating counterfeit products that plague the heavy equipment aftermarket.

Operational Benefits Beyond Suspension

Integration of the AZ9925521237 Balance Axle extends benefits beyond traditional suspension functions to impact overall vehicle dynamics. Advanced harmonic analysis reveals up to 19dB noise reduction in cabin measurements, directly improving driver comfort and reducing fatigue during extended hauls. By maintaining more consistent driveline angles, the component reduces universal joint operating angles below critical thresholds that accelerate cross-bearing wear patterns. Maintenance logs from bulk transport operators indicate 30% fewer drivetrain interventions in trucks equipped with genuine AZ9925521237 axles versus aftermarket alternatives. The improved stability also allows maximum payload utilization without exceeding frame stress limits through better distribution of dynamic forces. This weight distribution intelligence becomes especially important when navigating jurisdictions with strict axle-weight compliance requirements, preventing citations and loading delays. For specialized applications such as mobile crane carriers or concrete pumpers, the component’s enhanced rigidity provides critical stability for outrigger deployment by minimizing frame flex during jacking operations – a safety consideration verified through strain-gauge testing in certification laboratories.

Intelligent Manufacturing and Quality Assurance

Production of each AZ9925521237 Balance Axle incorporates real-time statistical process control at all machining stations to maintain geometric tolerances invisible to conventional measurement tools. This exacting precision ensures identical left/right characteristics for symmetric force distribution critical in suspension dynamics. The manufacturing ecosystem utilizes blockchain technology for material traceability – from steel mill ingots to final assembly – creating immutable quality records available for fleet maintenance audits. Final validation includes rotational balance testing to correct micro-imbalances below 5g-cm, preventing harmonic vibrations that become problematic at highway speeds. The coating process features a proprietary five-stage pretreatment that ensures phosphate layer adhesion before cathodic electrocoating, creating superior corrosion resistance verified through 1,500-hour salt spray testing. Post-production quality verification extends beyond dimensional checks to include ultrasonic inspection for internal flaws and magnetic particle testing for surface discontinuities – techniques typically reserved for aerospace components. This comprehensive approach to quality ensures every AZ9925521237 axle delivers the longevity expected from genuine factory components rather than unpredictable aftermarket alternatives.

Efficiency Through Integrated Design

The AZ9925521237 Balance Axle design exemplifies holistic engineering through weight-reduction strategies that maintain strength. Finite element analysis guided material placement only where structurally necessary, achieving 17% mass reduction over previous generation components without compromising load ratings. This weight savings translates directly to increased payload capacity within gross vehicle weight restrictions – a crucial advantage in competitive freight markets where profit margins depend on maximizing cargo tonnage. The simplified assembly design incorporates color-coded orientation markers that prevent installation errors, reducing workshop time by approximately 35% compared to competitor parts requiring specialized tools. Comprehensive technical documentation includes laser-etched QR codes providing instant access to installation torque sequences, maintenance schedules, and animated assembly guides directly on technicians’ mobile devices. The genuine AZ9925521237 component comes packaged with ISO-certified mounting hardware featuring surface treatments that prevent thread galling during installation – a frequent frustration with bulk-packaged fasteners. For fleet procurement specialists, the axle’s extended service life combined with predictable maintenance schedules enables more accurate total-cost-of-ownership projections, making this suspension component not just a mechanical necessity but a strategic financial decision.