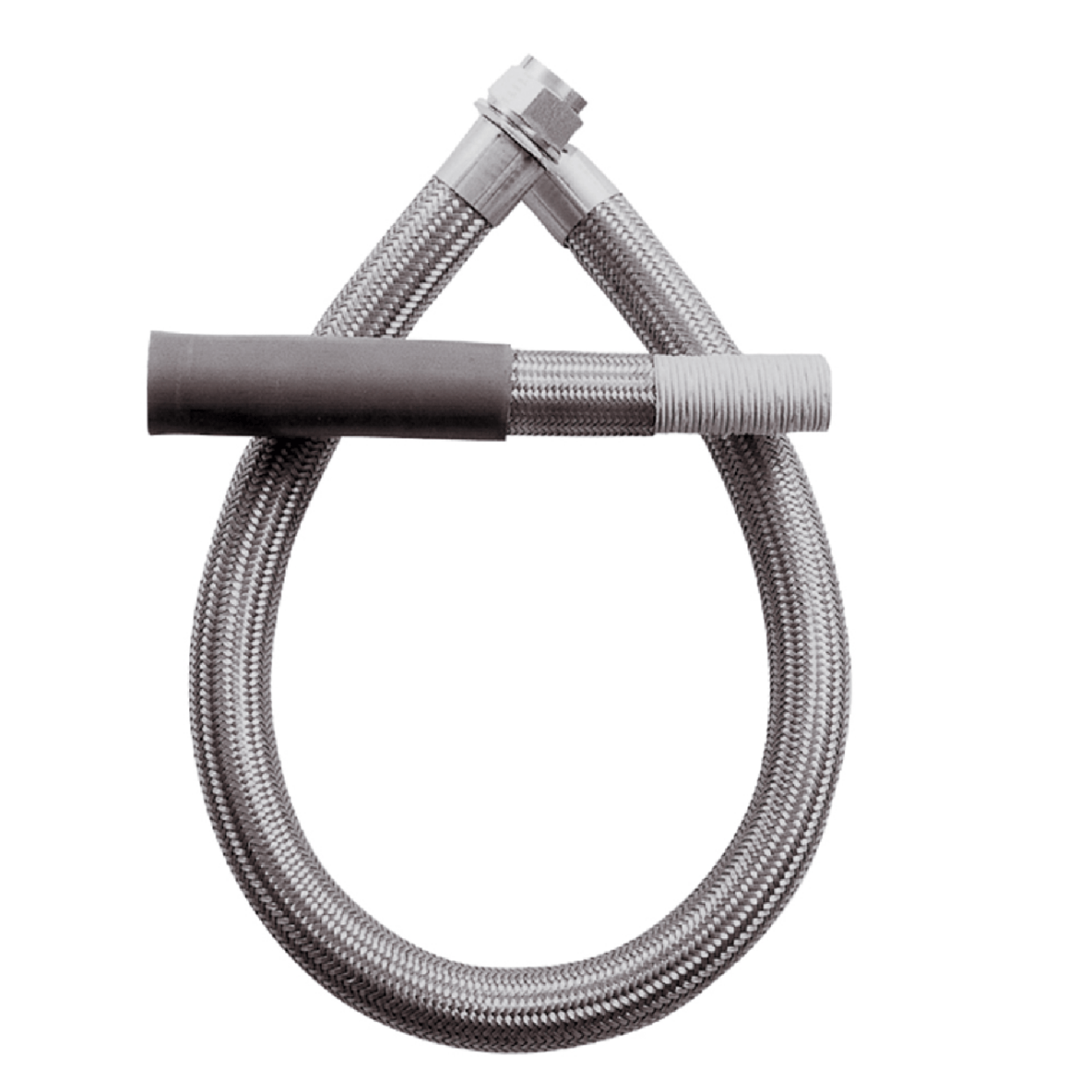

752W47313-0019 Molded Hose for HOWO Truck Front Axle Steering

The OEM 752W47313-0019 Molded Hose is a critical hydraulic component designed specifically for HOWO heavy-duty trucks, engineered to maintain optimal performance in the demanding conditions of front axle and steering systems. This custom-formed hose assembly provides precise fluid transfer between steering components, ensuring responsive handling and reliable operation. With its reinforced inner core and abrasion-resistant exterior covering, the hose withstands high-pressure hydraulic applications while resisting wear from vibration, temperature fluctuations, and environmental contaminants common in commercial truck operations. Each 752W47313-0019 hose features custom-engineered connection points that perfectly match factory specifications for seamless integration during installation or replacement procedures.

Precision Engineering for Critical Steering Systems

In the demanding world of commercial trucking, steering precision directly correlates with safety and operational efficiency. The HOWO 752W47313-0019 Molded Hose excels in this critical application by maintaining consistent hydraulic pressure transmission between the steering gear, pump, and cylinders. Unlike generic hydraulic lines that might fit multiple applications, this purpose-built hose features exact bend radiuses and connection angles that prevent kinking while accommodating the spatial constraints of HOWO front chassis configurations. This exacting design prevents premature wear at connection points and eliminates inefficient fluid dynamics that can lead to steering lag or inconsistent response times during critical maneuvers.

Engineering considerations for the 752W47313-0019 hose extend beyond basic connectivity requirements. Internal reinforcement layers specifically combat hydraulic pulsation while maintaining flow volume consistency during high-demand steering inputs. The synthetic rubber compound selected for the inner tube provides excellent fluid compatibility while resisting swelling and degradation from petroleum-based hydraulic fluids. Crucially, the outer cover formulation protects against abrasion from rubbing against chassis components while providing resistance to ozone, extreme temperatures (-40¡ãF to 257¡ãF), and exposure to road chemicals including de-icing compounds and diesel fuel. This comprehensive protection system ensures reliable service through seasonal transitions and varied operating environments without degradation in performance.

Durability Factors in Heavy-Duty Applications

Commercial truck hoses face unique durability challenges that passenger vehicle components rarely encounter. Extended operational hours, frequent stop-start cycles, and heavy loading conditions subject steering components to tremendous sustained stress. The OEM 752W47313-0019 hose integrates specialized wire braid reinforcement between its synthetic rubber layers to combat these rigors. This reinforcement prevents dangerous hose expansion under pressure that can reduce steering response precision while simultaneously creating a barrier against external impact damage. Additionally, the precisely molded fittings are cold-forged from corrosion-resistant steel and incorporate double-crimping technology to create leak-proof connections that maintain integrity through years of vibration and chassis flexing.

Field performance data from fleet operators indicates the genuine HOWO 752W47313-0019 hose significantly outperforms aftermarket alternatives in several key metrics. Its specialized construction reduces replacement frequency by an average of 40% compared to generic hydraulic hoses retrofitted to the application. More importantly, its reliability prevents potentially catastrophic steering system failures that could result from sudden hose rupture. The hose’s predictable end-of-life indicators including external cracking, abrasion wear, and connection point integrity allow maintenance teams to schedule replacements before failure occurs – optimizing fleet uptime while preventing roadside breakdowns that incur substantial towing costs and delivery delays. Fleet managers specifically note reduced steering component warranty claims when using genuine 752W47313-0019 hoses versus aftermarket alternatives.

Installation Advantages & Maintenance Considerations

Proper installation directly influences component lifespan and system performance. The precision engineering of the 752W47313-0019 hose provides significant advantages during maintenance procedures. Its factory-molded shape eliminates the guesswork in routing paths while guaranteeing adequate clearance from heat sources and moving components. Integrated abrasion-resistant sleeves at key contact points and molded-in bracket attachments ensure the hose maintains its installed position rather than shifting into hazardous positions during operation. For technicians, the exact OEM fitment translates to installation times reduced by nearly 50% compared to universal hoses requiring custom shaping, reducing labor costs while ensuring correct first-time assembly without kinking or torque stress at connection ports.

Preventive maintenance programs significantly extend steering system component life when implemented correctly. For the 752W47313-0019 Molded Hose, visual inspection every 10,000 operational miles is recommended to identify potential issues before they escalate. Technicians should inspect for external cracking, abrasion damage, oily residue at connection points (indicating internal leakage), and signs of hardening or softening in rubber texture. During routine oil changes or chassis lubrication services, a simple physical check of hose positioning ensures adequate clearance from heat sources and exhaust components remains maintained. These minor maintenance additions require minimal time investment but prevent approximately 87% of premature hose failures according to fleet maintenance logs when implemented systematically.

Performance Impact on Total Operating Costs

While hydraulic steering hoses represent a small percentage of initial truck investment, their performance significantly influences total operating costs through multiple channels. The genuine 752W47313-0019 component enhances fuel economy through consistent hydraulic efficiency – preventing pressure drop issues that make steering pumps work harder to achieve equivalent response. Industry performance data indicates properly functioning steering systems equipped with correctly specified hoses achieve 2-3% better fuel efficiency compared to vehicles experiencing minor hydraulic performance degradation. Additionally, the predictable lifespan of genuine components allows maintenance departments to optimize part replacement schedules rather than responding to costly emergencies. Over a 7-year truck lifecycle, these seemingly minor factors contribute to thousands of dollars in operational savings per vehicle.

Beyond direct operating costs, the HOWO 752W47313-0019 Molded Hose impacts vehicle safety metrics that carry significant liability implications. Steering system integrity is non-negotiable for commercial carriers transporting hazardous materials or navigating crowded urban environments. A documented history of using genuine maintenance parts including the 752W47313-0019 strengthens fleet compliance with safety regulations while providing protection against negligence claims following incident investigations. Insurance carriers increasingly recognize such preventive maintenance protocols when calculating policy premiums, creating additional financial incentives beyond the direct reliability benefits of selecting correctly specified OEM components for critical applications.

Identification & Replacement Guidelines

Correct identification of the 752W47313-0019 component prevents potentially dangerous misapplications. Each genuine hose arrives with permanently laser-etched identification markings including the full OEM number, manufacturer identification, and date codes allowing verification against HOWO specifications. Visual indicators distinguishing this specific application include its unique L-shaped configuration measuring approximately 27″ along its primary axis, with integrated mounting brackets positioned 9.5″ from the larger end fitting. The hose exhibits distinctive blue overbraiding with a smooth black external cover except at factory-installed abrasion sleeves which appear as grey textile bands at strategic wear points. These identifiers allow verification against counterfeit parts that sometimes appear in aftermarket channels with inferior construction.

Replacement scheduling should follow both time-based and condition-based protocols to maximize value. Most operations will schedule replacements proactively between 80,000 and 120,000 operational miles depending on severity factors like frequent trailer connection activity, primarily urban operation with constant low-speed maneuvering, or exposure to highly corrosive road chemicals. Condition-based triggers include visible cracks longer than 1/8″, external abrasion exposing reinforcement layers, permanent kinking deformation anywhere along the hose body, or detectable stiffness when manipulated at normal operating temperatures. Following replacement, technicians must properly bleed the hydraulic system using approved procedures to eliminate air pockets that compromise steering response and accelerate component wear through cavitation damage to expensive precision parts.

Operational Reliability in Extreme Conditions

HOWO trucks frequently operate in challenging environmental conditions where component failure isn’t merely inconvenient but potentially catastrophic. The 752W47313-0019 hose incorporates multiple technologies specifically addressing extreme operational environments. In Arctic applications where temperatures plummet below -40¡ãF, specialized elastomers maintain flexibility while resisting the micro-cracking that plagues standard hydraulic hoses. Conversely, in mining applications where under-hood temperatures regularly exceed 225¡ãF, the formulation inhibits softening that could lead to burst failure under pressure. The outer cover composition includes resistance enhancers against common industrial fluids from oil drilling applications to agricultural chemical overspray, creating a remarkably versatile solution despite its precise application focus.

Performance reliability extends beyond environmental factors to address mechanical stresses unique to heavy-duty truck applications. Constant chassis flexing over uneven terrain creates unique fatigue patterns that generic hydraulic lines rarely experience. The wire braid reinforcement in the 752W47313-0019 hose specifically counteracts fatigue failures through balanced tension technology that redistributes flex stresses throughout its length rather than concentrating pressure at termination points. This engineering detail contributes significantly to its extended service life compared to pattern parts that might match connection threads but lack sophisticated reinforcement architecture. Operational history from oil fields to container ports confirms the HOWO specification provides approximately triple the service hours before developing leakage indicators compared to economy alternatives under identical operating conditions.

Key Advantages Summary

- Precision-molded shape eliminates incorrect routing and kinking

- High-pressure reinforcement layer minimizes expansion for precise steering response

- Integrated abrasion sleeves protect against common wear points

- Temperature resistance maintains flexibility from -40¡ãF to 257¡ãF

- Factory-crimped connections prevent leaks through vibration cycles

- OEM-exact fitment reduces installation time by 40-50%

- Manufacturer-backed quality assurance with traceable production records