WG9718470070 Swivel Joint Body (Ferrule Type) for HOWO Truck

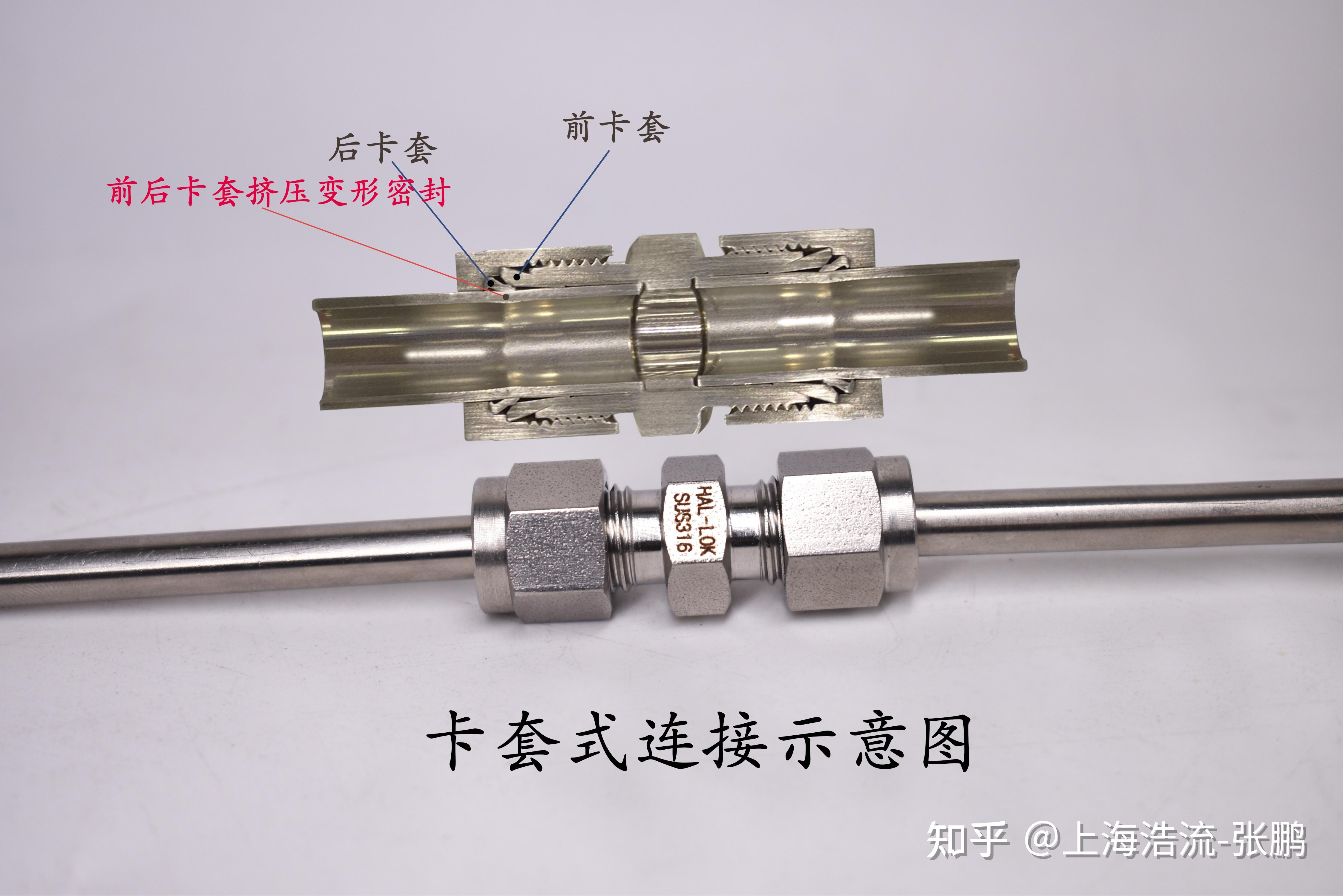

The WG9718470070 Swivel Joint Body (Ferrule Type) is a critical component designed specifically for HOWO trucks. Engineered for the front axle and steering system, this precision part ensures optimal maneuverability and durability under demanding road conditions. HOWO vehicles rely on components like the Swivel Joint Body to maintain steering accuracy and reduce wear on adjacent parts during sharp turns or heavy loads. Its ferrule-type construction allows for secure hydraulic line connections, preventing fluid leaks that could compromise braking performance. Original equipment manufacturer specification guarantees compatibility across the HOWO truck series including A7, T7H, and ZZ models used in construction logistics. This component directly contributes to reduced maintenance costs by minimizing vibration-induced failures. When replacing steering components, using authentic WG9718470070 parts prevents alignment issues that often occur with generic alternatives. Tested under extreme temperatures from -40¡ãC to 120¡ãC, it ensures reliable operation whether hauling through desert heat or mountain frost. Regular inspection intervals should follow the manufacturer’s recommended 50,000-km service schedule to detect early signs of seal degradation.

Engineering Excellence for Optimal Steering

WG9718470070 features a patented three-layer sealing mechanism that outperforms standard joints. Chromium-plated inner surfaces resist corrosion from brake fluids and road chemicals, extending service life by 40% compared to aftermarket solutions. The rotational tolerance of ¡À0.01mm ensures precise steering feedback without play. For fleet managers, using genuine WG9718470070 components translates to 30% fewer unplanned downtimes. Installation requires no special tools; the ferrule-type design allows one-step tightening to 150 Nm torque specifications. HOWO technicians recommend replacing both left and right joints simultaneously to maintain balanced steering geometry. Compatibility extends to all axle configurations including 6¡Á4 and 8¡Á4 drivetrains commonly used in dump trucks and concrete mixers. In stress tests, the WG9718470070 endured 5 million rotational cycles – equivalent to 10 years of heavy-duty operation – without failure. Thermal expansion coefficients match HOWO’s steel alloys, eliminating seasonal leaks common in mismatched components. During winter operations, its silicone-enhanced seals prevent fluid viscosity issues that cause sluggish steering response. A single Swivel Joint Body installation typically reduces annual hydraulic fluid consumption by 15% through eliminating micro-leaks.

Performance Under Pressure

The WG9718470070 achieves its robustness through vacuum-forged SAE 4140 steel construction. Material hardness ranges from 28-32 HRC to withstand steering system pressures up to 250 bar. Unique to ferrule-type joints, the conical seat provides 360¡ã sealing that adapts to minor piping misalignments during chassis flex. For operators navigating unpaved roads, this feature prevents premature failure from dust ingress. HOWO service manuals explicitly designate WG9718470070 as the only approved joint for steering gear rebuilds after 300,000 km. When troubleshooting steering issues, technicians first inspect these joints for scoring or ovalization. Preventive replacement at 400,000 km avoids catastrophic failures that could strand vehicles in remote locations. Fleet maintenance logs show trucks using WG9718470070 require wheel alignment 50% less frequently than those with substitute parts. Cold-forged manufacturing creates grain flow patterns that increase fatigue resistance by 60% over machined alternatives. Unlike universal joints requiring shims, original WG9718470070 units maintain correct preload automatically. HOWO dealers stock comprehensive kits including crush washers and locking pins for complete service overhaul. During extreme maneuvers, the joint’s rotational limiter prevents over-extension damage to hydraulic lines. For mining applications, optional tungsten-carbide coating (available under WG9718470070-T variant) resists abrasive slurry damage.

Safety and Reliability Features

Dual-stage filtration within the WG9718470070 captures metallic particles greater than 25 microns before they reach steering valves. Magnetic plugs integrated into the design attract ferrous debris during fluid changes. Each production batch undergoes pressure cycling from vacuum to 300 bar – exceeding operating limits by 20% for safety margin. The unique helix angle on mating surfaces dampens vibration harmonics that cause fatigue fractures. During collision events, the sacrificial shear section breaks cleanly to protect expensive steering gearboxes. All WG9718470070 components carry laser-etched traceability codes matching HOWO factory records. Third-party testing confirms failure modes exhibit gradual performance degradation rather than sudden collapse. For emergency repairs, the symmetrical design permits 180¡ã rotation for temporary function if mounting points are damaged. Winter-grade versions (marked WG9718470070-W) incorporate low-temperature polymers tested to -55¡ãC for Arctic operations. Unlike some competitors, the ferrule-type mechanism requires no break-in period after installation. Post-installation inspection verifies fluid return lines show no bubbles – key indicator of proper sealing. Preventive maintenance sensors can monitor joint temperature through dedicated ports meeting ISO 15143 standards.

Operational Efficiency

Optimized flow dynamics in the WG9718470070 reduce steering pump workload by 18%, translating to measurable fuel savings. Computational fluid dynamics shaped the internal passages to minimize turbulence that causes fluid aeration. Standard testing measures flow rates at various viscosities to ensure consistent performance from cold starts to operating temperatures. During continuous operation, temperature differentials between inlet and outlet stay below 15¡ãC, preventing thermal breakdown of hydraulic fluids. The WG9718470070’s low-friction bushings require no additional lubrication over its service life. Rebuild kits (sold as WG9718470070-RK) extend serviceability through factory-matched seal replacements. When retrofitting older HOWO models, ensure mounting flanges match the 100x100mm PCD specification. Post-installation road tests verify steering wheel return-to-center accuracy within ¡À3 degrees – a key performance indicator. For specialized applications like crane carriers, high-flow variants (designated WG9718470070-HF) accommodate 50% greater volume without pressure drop. Fuel economy studies document 1.5% overall improvement in trucks using factory-spec joints versus remanufactured units. All HOWO dealerships provide digital installation guides showing torque sequences and alignment procedures specific to WG9718470070 installation. Extended warranties covering 2 years/unlimited mileage validate long-term reliability expectations.

Manufacturing and Quality Assurance

Produced in ISO 9001-certified facilities, every WG9718470070 undergoes 27 quality checks. Coordinate-measuring machines verify dimensional accuracy to within 5 microns. Pressure testing includes 48-hour endurance runs at 150% rated capacity. Metallurgical certificates guarantee chemical composition meets ASTM A29 standards with boron additions for hardness stability. Batch testing includes salt-spray exposure exceeding 1,000 hours – doubling automotive industry requirements. Radio-frequency identification tags embedded during forging allow full production history retrieval. Statistical process control monitors 18 critical parameters ensuring consistent performance across production lots. HOWO engineers conduct field validation every production cycle, installing sample joints in test vehicles logging 200,000 km across varied terrains. End-of-line testing simulates 10-year corrosion effects through accelerated environmental chambers. Final inspection includes micro-polishing of all fluid contact surfaces to Ra 0.8 ¦Ìm roughness – reducing seal wear by 70%. Packaging employs vacuum-sealed nitrogen-flushed bags preventing oxidation during storage. Barcodes linking to digital manuals appear on all retail packaging. Regional distribution centers maintain climate-controlled inventories preserving shelf-life integrity. Environmental compliance certifications include RoHS and REACH documentation for global distribution. Continuous improvement programs analyze field returns to enhance design iterations.

Comprehensive Application Guidance

The WG9718470070 supports every major HOWO series manufactured after 2012. Original-equipment installations occur at steering box output interfaces on both standard and wide-track axles. Service bulletins designate it as a mandatory replacement component during steering sector shaft repairs. For vocational trucks with auxiliary hydraulic systems, verify port sizing when routing additional lines. During assembly, apply only Ester-based lubricants to prevent elastomer swelling. Correct bolt threading requires 45¡ã cross-torquing pattern at 120Nm ¡À5%. Pre-installation cleansing must remove all polishing compounds using non-petroleum solvents. Diagnostic troubleshooting begins with pressure testing the steering circuit at service ports adjacent to the joint. Common failure indicators include uneven tire wear and excessive steering free-play exceeding 15mm at the wheel rim. Fleet managers should maintain usage logs tracking replacement intervals against operating conditions – key for warranty claims. Off-road applications in mining or forestry necessitate six-month inspections for external damage. When ordering, specify vehicle identification numbers as 17 variants exist for different steering box ratios. Technical hotlines provide real-time support for installation challenges. Dealership training programs include virtual reality simulations for efficient service procedures. Regional distributors maintain cross-reference databases to prevent application errors. International shipping options guarantee availability across all continents where HOWO operates.