810W35609-0013 Planetary Gear for HOWO Truck Drive Axle

The 810W35609-0013 planetary gear is engineered specifically for HOWO trucks’ drive axle systems, delivering unmatched power transmission efficiency. As an essential component in heavy-duty transportation, this OEM-specific mechanism ensures optimal torque distribution while minimizing energy loss. Designed to withstand extreme operating conditions, the planetary gear arrangement reduces stress on individual components, extending the lifespan of your HOWO truck’s drivetrain. The precision engineering behind part number 810W35609-0013 guarantees seamless integration with SINOTRUK’s axle assemblies, providing reliability that logistics professionals trust across global supply chains.

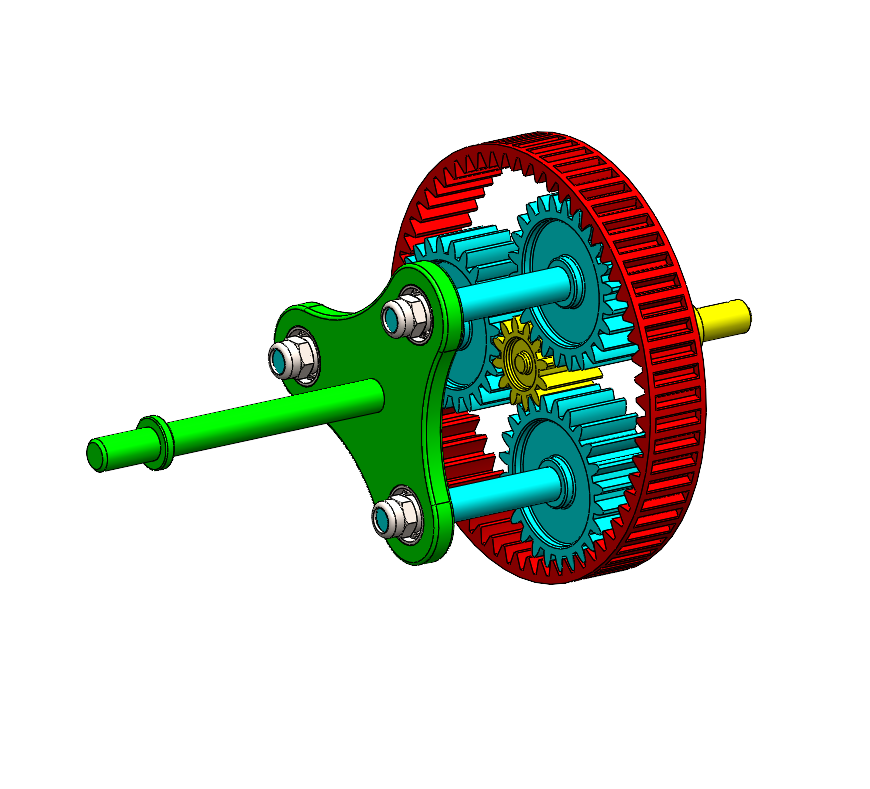

Planetary gear systems represent the pinnacle of transmission technology in commercial vehicles, and the 810W35609-0013 model exemplifies this sophistication. Unlike conventional gear configurations, this planetary arrangement features a central sun gear surrounded by planet gears that rotate within a ring gear enclosure. This compact yet powerful design provides multiple contact points for force distribution, making it exceptionally durable for long-haul transportation. When integrated into HOWO truck axles, the 810W35609-0013 significantly reduces vibration and noise pollution, contributing to driver comfort during extended journeys.

The manufacturing process for this planetary gear emphasizes material integrity and dimensional precision. High-grade alloy steel undergoes specialized heat treatment to achieve optimal surface hardness while maintaining core toughness. This dual-property characteristic ensures the 810W35609-0013 can absorb shock loads without developing stress fractures. Each component undergoes rigorous quality validation to guarantee precise tooth profiling and consistent meshing action with mating parts throughout the powertrain system.

For fleet managers operating HOWO trucks in challenging environments, the 810W35609-0013 provides operational advantages beyond basic power transmission. Its optimized lubrication channels maintain oil flow to critical wear surfaces even under steep inclines or overload conditions. The gear’s thermal management properties prevent localized overheating that typically occurs during extended downhill braking scenarios. This attention to thermal dynamics extends service intervals significantly compared to standard planetary assemblies.

Implementation of the 810W35609-0013 in your HOWO drive axle generates measurable economic benefits. Increased fuel efficiency stems from reduced internal friction losses within the gear cluster. Maintenance costs decrease due to the superior wear resistance and minimal backlash development over operational cycles. Many logistics companies report reduced downtime incidents after switching to this specific planetary gear configuration in their SINOTRUK commercial fleets.

Engineering innovations in the latest 810W35609-0013 iteration include micro-textured gear surfaces that enhance lubricant retention at critical contact points. This microscopic surface technology creates miniature reservoirs that continuously supply lubrication film during high-stress operations. Additionally, the updated design incorporates reinforced carriers that distribute planetary loads more evenly across supporting structures. These enhancements contribute to the exceptional durability that makes this planetary gear ideal for mining, construction, and long-distance freight applications.

Compatibility remains a crucial advantage for the 810W35609-0013 specification. Designed as a direct replacement for original HOWO drive axle components, installation requires no modifications or adapter kits. This plug-and-play functionality minimizes vehicle downtime during maintenance operations. Mechanics consistently report straightforward installation procedures that follow standard SINOTRUK protocols, significantly reducing the potential for assembly errors that could compromise performance.

Planetary gear functionality extends beyond basic power transfer. In modern HOWO drive axles, the 810W35609-0013 contributes to intelligent drivetrain management systems. The consistent rotational behavior enables more accurate wheel speed monitoring and traction control responses. This becomes particularly valuable when navigating slippery surfaces or when handling uneven weight distributions across trailer configurations. The precision engineering of this part ensures predictable torque delivery essential for advanced vehicle stability programs.

Environmental sustainability considerations have influenced recent improvements to the 810W35609-0013. Material selection prioritizes recyclable alloys while machining processes minimize metal waste generation. The optimized design reduces friction-related energy losses, effectively lowering CO2 emissions per kilometer traveled. Transportation companies committed to reducing their environmental impact appreciate the measurable carbon footprint reduction achieved through this high-efficiency planetary gear implementation.

Operators consistently report noticeable performance improvements when upgrading to the 810W35609-0013 planetary gear. The most frequently mentioned benefits include smoother gear transitions during hill ascents, especially when carrying maximum payload capacities. Highway driving stability improves substantially due to reduced vibration transfer from the drive axle to the cab structure. Long-term users observe fewer oil leakage issues and more consistent lubricant quality retention between service intervals when compared to aftermarket alternatives.

Maintenance considerations for this planetary gear focus on simple inspection protocols. Visual checks of gear tooth contact patterns during routine service appointments help identify alignment issues before they cause significant damage. Oil analysis provides early detection of microscopic wear particles, allowing proactive component replacement. These straightforward monitoring techniques help extend the operational lifespan beyond typical heavy-duty gear service expectations.

Global availability for the 810W35609-0013 ensures consistent maintenance programs for internationally operating fleets. Authorized distribution centers stock genuine parts to guarantee identical performance characteristics across different continents. This supply chain reliability eliminates concerns about inconsistent gear quality that could create mechanical reliability issues during critical transport operations far from service facilities.

Technical specifications reveal the engineering excellence behind this planetary gear. The carefully calculated gear ratios optimize torque conversion across varying speed ranges, providing responsive acceleration without compromising high-speed efficiency. Backlash tolerances measure significantly tighter than industry standards, eliminating the characteristic clunking sounds during directional reversals common in lower-quality transmissions. These precise operational parameters establish new benchmarks for drivetrain refinement in heavy commercial vehicles.

Thermal imaging studies demonstrate the 810W35609-0013 maintains remarkably uniform temperature distribution throughout prolonged heavy-load operation. Unlike competitive planetary systems that develop localized hot spots near gear roots, the optimized tooth profile and enhanced lubrication delivery prevent dangerous thermal gradients that could cause metallurgical failure. This thermal stability provides additional safety assurance during emergency braking scenarios that generate sudden reversals in driveline energy transfer.

HOWO technical advisors consistently recommend the 810W35609-0013 for specialized transport applications involving steep terrain and challenging weather conditions. The gear’s consistent performance during cold starts reduces powertrain stress in freezing temperatures, while its exceptional heat tolerance maintains integrity through desert operations. This versatility makes this planetary assembly suitable for global logistics operations facing diverse environmental challenges without requiring region-specific modifications.

Performance validation for the 810W35609-0013 includes multi-stage endurance testing that simulates decades of continuous operation. Accelerated lifecycle analysis reveals significantly reduced wear particle accumulation in lubrication systems, indicating minimal material fatigue degradation. Such extended longevity testing validates the manufacturer’s confidence in providing industry-leading warranty coverage specifically for HOWO commercial transportation applications.