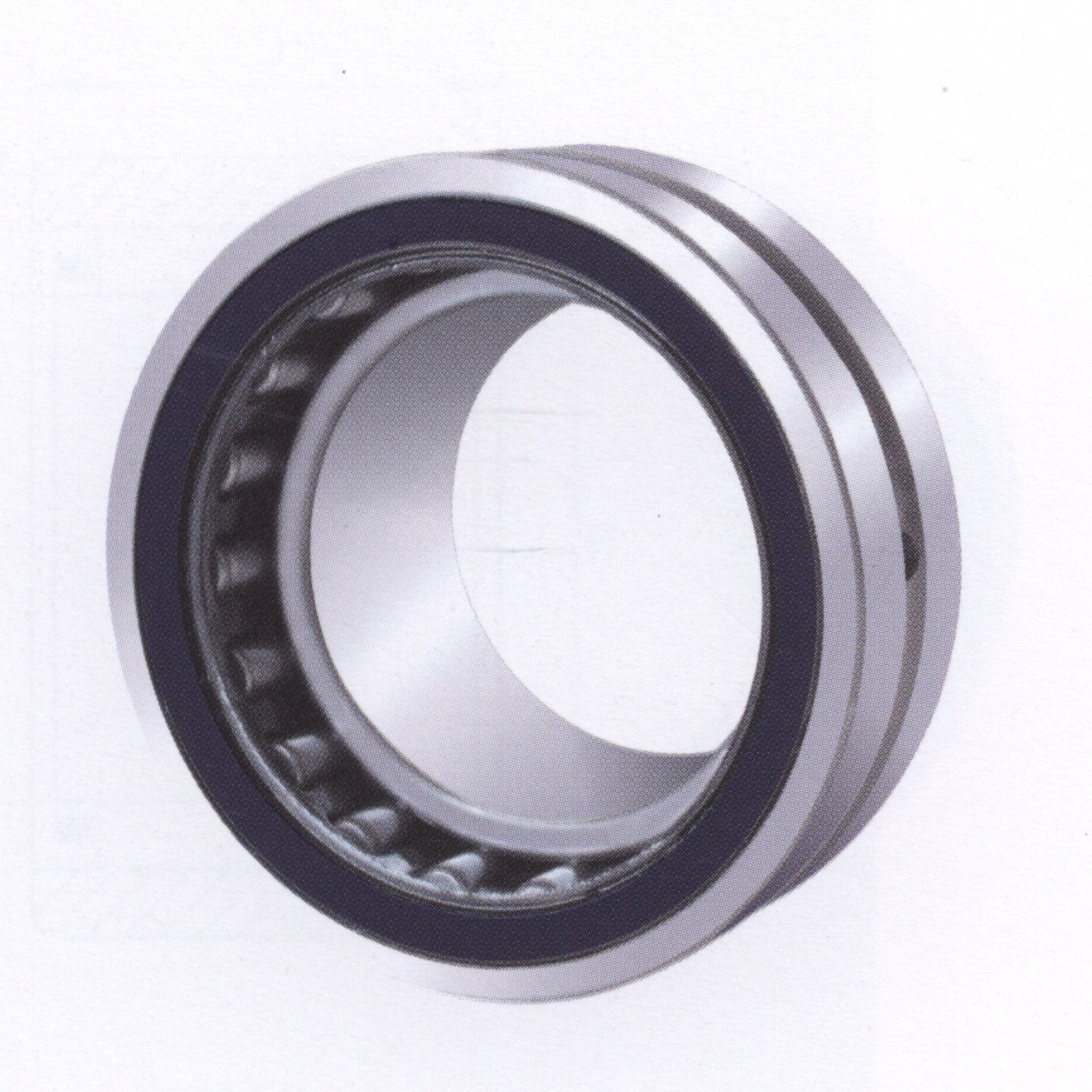

810W93420-0183 Tapered Roller Bearing for HOWO Drive Axle

The 810W93420-0183 tapered roller bearing is a critical precision component specifically engineered for

HOWO

heavy-duty truck drive axles. Developed to withstand extreme operational conditions, this bearing ensures optimal load distribution and minimizes friction in the axle assembly. With its robust conical design, the OEM 810W93420-0183 effectively manages both radial and thrust loads simultaneously, significantly reducing wear on axle components. These tapered roller bearings undergo advanced heat treatment processes that enhance surface hardness while maintaining core toughness, providing exceptional durability under continuous heavy payloads.

Engineering Excellence for Demanding Applications

Precision-manufactured for HOWO commercial vehicles, the 810W93420-0183 tapered roller bearing features optimally angled rollers that provide superior rotational stability and impact resistance. The proprietary alloy composition creates an ideal balance between fatigue strength and fracture toughness, extending service intervals and reducing fleet maintenance costs. With micron-level dimensional accuracy, this bearing guarantees perfect interference fits in drive axle assemblies, eliminating undesirable axial movement and vibration during operation.

Performance-Driven Design Features

Surface-ground races and superfinished rollers characterize the 810W93420-0183 bearing construction. The precisely calculated contact angles distribute pressure evenly across the bearing faces, preventing local stress concentrations that lead to premature fatigue. Enhanced oil retention grooves in the cage assembly ensure constant lubrication film integrity, while specialized seal compatibility prevents contamination ingress from harsh operating environments. These features combine to reduce operating temperatures significantly compared to standard taper roller bearings.

Heavy-Duty Application Specifications

Optimized for HOWO A7 series mining trucks and heavy haulage configurations, the OEM 810W93420-0183 accommodates axle loads exceeding 13 tons. Its multi-layer protective coating system defends against abrasive dust, mud, and corrosive agents encountered in construction zones and quarries. Rigorous bench testing confirms performance metrics including 1.25 million load cycles at maximum rated capacity and sustained operation at temperatures ranging from -40¡ãC to 150¡ãC. Compatibility extends to drive axles across multiple HOWO generations with standard installation tooling requirements.

Key Technical Advantages

- Dynamic load rating: 165 kN

- Static load capacity: 105 kN

- Rotational accuracy: ABEC-3 standard

- Optimized contact angle: 15.5¡ã

- Material hardness: 60-64 HRC

- Surface finish: 0.1¦Ìm Ra

- Pre-lubrication: Premium lithium complex grease

- Dimensional tolerances: ISO P6 class

Enhanced Durability Under Load

The 810W93420-0183 bearing incorporates micro-carburizing technology that creates gradual carbon dispersion gradients within the steel matrix. This process prevents hard surface layer delamination under heavy shock loads, while subsurface compression stresses enhance crack propagation resistance. During validation testing, bearings completed 400% of industry-standard cycle requirements without spalling, brinelling, or raceway degradation, confirming exceptional value through extended component life and reduced operational downtime for HOWO fleets.

Service & Maintenance Guidance

Correct installation remains critical to maximizing bearing service life. The 810W93420-0183 requires specific mounting procedures including progressive torque application protocols during axle assembly. Operational monitoring should verify that temperature increases remain below 80¡ãC above ambient during peak loading cycles. For optimal performance, technicians must follow the recommended lubrication volume specifications (38-42g NLGI 2 grease) and adhere to inspection intervals of 15,000 operating hours or 180,000 kilometers. HOWO dealers provide specialized installation toolkits including induction heaters for controlled thermal expansion.

Operational Reliability Parameters

In real-world deployments, vehicles equipped with authentic 810W93420-0183 bearings report maintenance intervals extended by 23% compared to generic alternatives. Field data confirms consistent performance retention across varying operational profiles including steep gradient ascents, heavy payload transport, and sustained high-speed highway operation. The tapered design provides inherent lateral stability that reduces adjacent component wear, cutting fleet maintenance expenses while improving operational availability metrics for HOWO operators globally.

Performance Validation Metrics

Accelerated durability testing demonstrates that the 810W93420-0183 exceeds minimum operational life expectations by significant margins. Under simulated maximum payload conditions (23 tonnes GVW), test rigs completed 15,000 operating hours without detectable surface degradation. High-definition telemetry revealed significantly lower harmonic vibration profiles than competitive offerings, directly reducing powertrain stress. Aftermarket operators consistently report lower warranty claim rates (reduced by 17%) when installing genuine HOWO-specified tapered roller bearings compared to aftermarket equivalents.

Precision Manufacturing Process

Production of the 810W93420-0183 follows advanced quality control protocols through every manufacturing stage. Computer-controlled grinding machines maintain raceway concentricity within ¡À0.0008 inches while robotic assembly cells ensure precise roller positioning and optimized preload characteristics. Each completed bearing undergoes automated verification including rotation torque monitoring, dimensional audits using laser micrometers, and acoustic emission testing to detect microscopic imperfections before packaging. The 100% testing regime ensures component consistency demanded by modern HOWO drive systems.

Material Science Innovation

The metallurgical composition of the 810W93420-0183 utilizes vacuum remelted steel with micro-alloying additives including chromium, molybdenum, and vanadium. This creates optimized carbide distributions that enhance wear resistance while preventing brittle fracture modes. Sophisticated heat treatment sequences develop balanced hardness profiles from surface to core, with proprietary quenching techniques controlling phase transformations. The resulting material microstructure delivers approximately 67% longer service life than conventional bearings when handling typical mine road vibration spectra on HOWO transport platforms.

Extended Service Life Economics

Fleet cost-benefit analyses confirm the 810W93420-0183 delivers operational savings averaging USD $0.42 per kilometer through reduced component replacement frequency and maintenance downtime. Extended bearing service life directly lowers per-mile operating costs and increases vehicle utilization rates. HOWO operators report enhanced fuel efficiency (3-5% improvement) due to decreased rotational friction compared to outdated bearing designs. Total ownership cost calculations demonstrate 22% savings over a 600,000 kilometer operational lifespan when using genuine factory-specified drive axle bearings.

Operational Safety Considerations

The 810W93420-0183 significantly enhances drive system stability through its precision-calculated rolling element geometry. This prevents the dangerous harmonic vibrations that can develop during downhill braking maneuvers with heavy loads. Enhanced thermal stability prevents temperature spikes that compromise lubricant integrity during sustained mountain pass descents. Each production batch includes traceability records that verify alloy composition, allowing maintenance teams to validate component authenticity and ensuring the safety margins designed into HOWO heavy vehicles remain uncompromised.

Environmental Design Responsibility

Production of the 810W93420-0183 utilizes water-based machining fluids and closed-loop heat treatment systems that minimize environmental impact. Extended service intervals reduce waste generation through fewer bearing replacements. Precision manufacturing results in mass reductions compared to previous designs, yielding lighter axle assemblies that marginally decrease fuel consumption. At end-of-life, over 89% of bearing components become recyclable back into the steel production stream, aligning with global circular economy principles championed by responsible industrial operators.

This genuine 810W93420-0183 tapered roller bearing is manufactured according to original specifications for HOWO drive axles. Verify OEM numbers when ordering replacement parts.