AZ9761349003 Brake Backing Plate for HOWO Truck Drive Axle

The AZ9761349003 brake backing plate assembly is engineered specifically for heavy-duty HOWO trucks operating under demanding conditions. As an essential component of the drive axle braking system, this OEM-certified part guarantees perfect compatibility with your HOWO vehicle’s specifications. Designed to withstand extreme pressure and heat fluctuations during intensive braking operations, each component undergoes rigorous quality validation to ensure longevity and reliability throughout its service life. Commercial fleet managers recognize the critical function of the brake backing plate in maintaining operational safety standards and preventing costly downtime incidents.

Precision Engineering for Maximum Performance

Precision-formed using advanced stamping techniques, the AZ9761349003 assembly maintains consistent thickness and structural integrity across all contact surfaces. This manufacturing consistency eliminates warping under thermal stress, a common failure point in inferior brake components. The corrosion-resistant coating applied during production provides an extra defense layer against road chemicals and moisture exposure, particularly vital for transport vehicles operating in coastal regions or winter road conditions where salt corrosion accelerates wear patterns. Proper installation ensures uniform brake shoe alignment which directly impacts stopping power efficiency and prevents uneven pad wear scenarios.

Vehicle Compatibility and Installation

This specialized backing plate assembly interfaces seamlessly with HOWO’s proprietary braking architecture. Technicians note the simplified installation process due to exact factory-matching bolt patterns and pre-calibrated anchor pin positioning. The AZ9761349003 replaces multiple older part variants through its universal mounting system compatible with various model years of HOWO dump trucks, tractor units, and heavy cargo transporters. Proper mounting torque specifications must be maintained during installation to avoid stress fractures and ensure optimal brake shoe return spring functionality. Regular visual inspections of dust shield integrity and debris clearance should form part of routine maintenance schedules to prevent particulate accumulation.

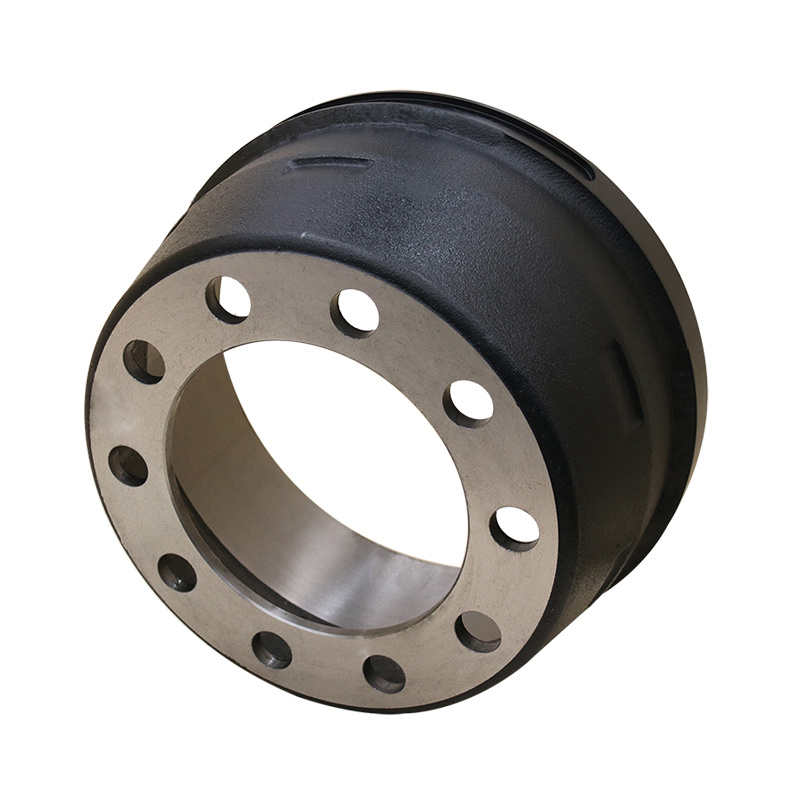

Technical Specifications Overview

Constructed from high-grade stamped steel, the backing plate features precisely positioned mounting holes matching the OEM dimensions. The wear-resistant surface coating exceeds industry standards for salt spray resistance, providing enhanced durability. Critical dimensional tolerances are maintained within ¡À0.15mm ensuring vibration-free operation even at maximum payload capacities. Compatibility extends across HOWO’s H-series including popular 6×4 and 8×4 configurations used in mining, construction, and long-haul applications. When replacing worn components, it’s recommended to inspect related brake hardware for synergistic wear patterns.

Operational Benefits

Fleet operators report measurable cost reductions after switching to genuine AZ9761349003 components. The extended service intervals directly translate to reduced maintenance expenses while maintaining compliance with transportation safety regulations. Properly functioning backing plates reduce harmonic vibrations that can cause premature wheel bearing failures, creating additional savings potential. The thermal management properties prevent heat buildup that degrades brake fluid integrity, maintaining consistent pedal feel throughout demanding descent operations. Additional safety benefits include preventing brake shoe misalignment that can lead to directional pull during emergency stopping maneuvers.

Maintenance Best Practices

Regular inspection intervals should include checking for signs of structural fatigue around mounting points and evidence of heat discoloration beyond normal operating parameters. During seasonal maintenance cycles, thorough cleaning of backing plate surfaces prevents corrosive buildup while allowing technicians to identify hairline cracks before they propagate into structural failures. Always verify the presence of proper dust shield clearance as material buildup accelerates corrosion. For vehicles operating in exceptionally muddy conditions, consider shortening inspection intervals to monitor component integrity. Proper lubrication of cam bushings and anchor pins extends service life while maintaining smooth braking actuation.

Genuine Component Advantages

HOWO genuine components like the AZ9761349003 undergo factory validation testing that replicates millions of braking cycles under variable load conditions. This extensive testing reveals potential failure modes that get addressed through engineering refinements before production. Third-party alternatives frequently lack these validation protocols, creating operational risks. The precision manufacturing ensures consistent hole alignment for brake spider mounting, preventing installation difficulties and eliminating the need for destructive modifications sometimes required with aftermarket alternatives. Documentation accompanying authentic components provides warranty protections unavailable with generic equivalents.

Application-Specific Design Features

The AZ9761349003 design incorporates numerous application-specific improvements developed through HOWO’s engineering feedback loop. Reinforced stress points address weaknesses identified in earlier-generation components used on mining trucks operating in high-vibration environments. Improved thermal dissipation prevents heat-induced warping that historically affected vehicles traveling mountain routes with extended descent braking. Optimized dust shield geometry reduces material buildup common in agricultural applications while hardened contact pads extend service life for municipal vehicles operating with frequent stop-start cycles. Each iteration incorporates real-world feedback for continuous improvement.

System Integration Importance

This backing plate assembly functions as the structural foundation for multiple brake system components. It must provide secure anchor points for return springs while maintaining precise camshaft alignment for proper brake shoe actuation. Even minor deviations in backing plate positioning dramatically affect braking performance and wear characteristics. The complex interaction between anchor pins, rollers, and cam bushings demands perfect component alignment only achieved through factory-specified manufacturing tolerances. Compromising on any element of the foundation compromises the entire braking system’s effectiveness and longevity. This systems-approach mindset differentiates genuine components from generic replacements.

Complete Drivetrain Solutions

While the AZ9761349003 focuses specifically on the braking system, HOWO integrates this component within broader vehicle design philosophy. The brake backing plate operates in concert with drivetrain components optimized for weight distribution and power transfer efficiency. Fleet managers appreciate how this systematic coordination reduces vibrations that otherwise create collateral damage to surrounding components. Genuine parts guarantee this engineering integration works as intended without introducing compatibility complications or creating subsystem interference. The AZ9761349003 forms just one element in a comprehensive approach to vehicle reliability and operating cost management.

Operational Cost Management

Commercial vehicle operators confirm measurable reductions in overall operating expenses when using genuine components like the AZ9761349003. The extended service life directly reduces replacement part expenditures while the precision engineering prevents cascading failures to adjacent components. Maintenance shops report decreased labor times for brake servicing jobs due to perfect fitment characteristics. Reduced downtime frequency creates significant revenue protection opportunities, especially for vehicles operating on time-sensitive contracts. These economic factors combined with enhanced safety performance establish a compelling business case beyond initial purchase price considerations.

Proactive Replacement Planning

Experienced maintenance supervisors develop proactive replacement schedules for foundational components like the AZ9761349003 backing plate assembly. This prevents inconvenient roadside failures that result in expensive emergency service calls and project delays. Monitoring brake shoe wear patterns provides valuable insight into backing plate condition since uneven wear often indicates developing alignment issues. Fleet managers should maintain strategic parts inventory for critical components to eliminate downtime waiting for replacement shipments. Documentation of installation dates creates predictable maintenance forecasting for budgeting purposes while ensuring vehicle safety compliance.

Technical Support Resources

HOWO distributors provide specialized technical assistance regarding the AZ9761349003 application and maintenance. Resource libraries include detailed installation videos, torque specification guides, and compatibility charts by vehicle identification numbers. This technical support ecosystem ensures proper part utilization and helps avoid installation errors that compromise performance. Regional service centers maintain master technicians trained in specialized procedures for braking system maintenance beyond standard shop capabilities. Documentation accompanying each genuine part includes QR codes linking directly to manufacturer-supported installation resources and warranty registration portals.