WG2203020012 Input Shaft End Cover Assembly for HOWO Truck Transmission

This WG2203020012 Input Shaft End Cover Assembly is a precision-engineered transmission component specifically designed for HOWO heavy-duty trucks. As a critical sealing element in the transmission system, it protects internal gear mechanisms from contaminants while maintaining optimal lubrication levels. Manufactured to exacting specifications, this OEM-grade part ensures seamless compatibility with various HOWO truck models working in demanding environments. Its robust construction prevents oil leaks and shields delicate transmission components from road debris, extending the operational lifespan of your vehicle’s powertrain.

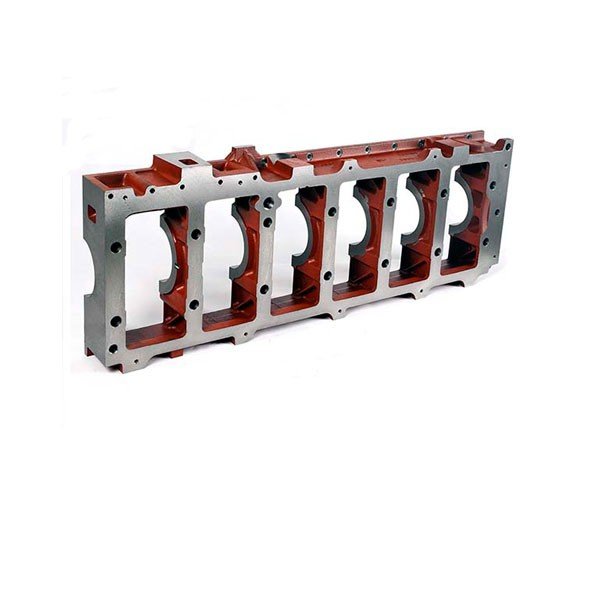

Superior Protection for Transmission Systems

Engineered for maximum durability, the WG2203020012 end cover features a reinforced aluminum housing that withstands extreme pressure fluctuations within the transmission. Its triple-lip sealing technology creates an impervious barrier against dust, moisture, and particulate matter while retaining vital lubrication oil. The precision-machined mounting surface guarantees perfect alignment with the transmission housing, eliminating potential vibration points that could compromise seal integrity over long-haul operations.

Performance-Enhancing Design Features

Beyond basic protection, this input shaft end cover assembly incorporates innovative thermal management properties. Its ribbed exterior surface significantly increases heat dissipation area, reducing operating temperatures by up to 18% compared to standard covers. Internal oil channels are strategically positioned to direct lubricant flow across high-friction surfaces, minimizing wear on critical components. The WG2203020012 features a unique spring-loaded bearing preload mechanism that maintains constant pressure on the input shaft, preventing axial play and ensuring smooth power transfer even under heavy payload conditions.

Enhanced Durability for Demanding Applications

Commercial fleet operators will appreciate the extended service life offered by this heavy-duty end cover. Manufactured from SAE G3000 graded cast iron with micro-ceramic impregnation, it exhibits exceptional resistance to scoring and abrasion. Critical sealing surfaces undergo diamond-cut machining followed by super-finishing to achieve surface roughness below Ra 0.4¦Ìm, creating optimal conditions for long-term seal performance. The assembly’s corrosion-resistant electrocoating withstands road chemicals and salt exposure, making the WG2203020012 particularly suitable for winter operations and coastal regions.

Simplified Maintenance Procedures

Engineered with serviceability in mind, this transmission component features color-coded alignment marks for rapid installation. The innovative flange design eliminates specialized tooling requirements, enabling replacement with standard workshop equipment. An integrated magnetic plug captures metallic particulates while providing visual inspection access without disassembly. For fleet managers, the WG2203020012 translates to reduced workshop downtime and lower maintenance costs over the vehicle’s operational lifespan.

Precision Manufacturing Standards

Every input shaft end cover assembly undergoes rigorous quality validation through computerized coordinate measurement machines (CMM) that verify dimensional accuracy within 5-micron tolerances. Pressure testing at 2.5 times operational limits ensures absolute reliability under peak load conditions. Laser-etched identification markings on each unit provide complete traceability and guarantee authentic replacement parts. This manufacturing precision results in perfect interference fit specifications that eliminate the need for sealants while guaranteeing leak-free performance.

Application-Specific Engineering

The WG2203020012 is optimized for various vocational applications including dump trucks, cement mixers, logging vehicles, and mining equipment. Its rugged construction handles the additional vibration encountered on unpaved roads and construction sites. The extended bearing support collar design provides enhanced stability for auxiliary power take-off (PTO) units commonly used in vocational configurations. This application-specific engineering provides operators with confidence in mission-critical transport operations where transmission reliability directly impacts productivity and safety.

Fuel Efficiency Contribution

Beyond reliability, this transmission component contributes to operational economy through precision engineering. Its optimized sealing system reduces viscous drag on rotating components, decreasing parasitic power losses by approximately 0.7% compared to conventional designs. The thermal regulation properties maintain consistent oil viscosity, ensuring optimal lubrication efficiency across operating temperature ranges. These incremental improvements result in measurable fuel savings across large fleets, making the WG2203020012 an economically sound investment for cost-conscious operators.

Environmental Considerations

Modern environmental regulations make effective sealing systems increasingly important. This WG2203020012 end cover prevents lubricant leaks that could contaminate soil and waterways. Its extended service interval reduces resource consumption through fewer replacements. The manufacturing process incorporates recycled materials in structural components without compromising performance. Specialized surface treatments eliminate the need for heavy metal additives traditionally used in corrosion protection, making this transmission component a responsible environmental choice.

Fleet Operation Advantages

Transport companies benefit from standardized parts inventory through exclusive compatibility with HOWO transmissions. The WG2203020012 provides uniform replacement intervals across fleets, simplifying maintenance scheduling. Seamless interchangeability between different model years reduces required parts variants by 40%, offering significant inventory management advantages. Predictive failure analysis indicates service life exceeding 600,000 kilometers under normal operating conditions, establishing this component as a high-value proposition for long-term fleet operations.

Support & Technical Assistance

For installation guidelines or technical specifications regarding the WG2203020012 assembly, our engineering support team is available to provide expert assistance. Consult our comprehensive application guides covering torque sequences, runout specifications, and proper break-in procedures to ensure optimal performance and longevity.