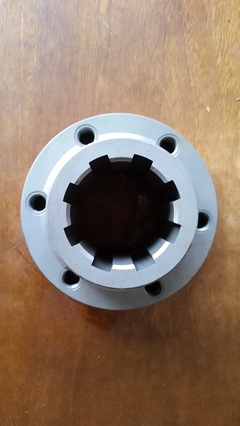

HOWO Transmission Output Flange WG2210100035 180 Face Teeth

Discover the precision-engineered WG2210100035 output flange specifically designed for HOWO truck transmissions. This HOWO-compatible output flange features 180 face teeth configuration, ensuring optimal torque transfer and drivetrain efficiency. Manufactured to OEM specifications, this transmission component delivers exceptional durability under heavy-load conditions while maintaining perfect alignment with your transmission system. Truck operators across global markets trust this flange for its consistent performance and seamless compatibility with HOWO vehicles.

The WG2210100035 output flange serves as a critical connection point in the drivetrain system of HOWO trucks, translating engine power through the transmission to the wheels. Its 180-tooth face design ensures maximum contact area for efficient power transfer while minimizing vibration during operation. This component undergoes rigorous quality checks to guarantee perfect dimensional accuracy, maintaining the strict tolerances required for heavy-duty applications. Truck operators choosing this flange experience smoother gear transitions and reduced driveline shock during load shifts.

Installation compatibility makes this output flange an essential replacement part for HOWO truck models produced between 2015-2023. The WG2210100035 is engineered to match the original transmission interface specifications precisely, enabling mechanics to replace worn components without modifications. This flange features advanced surface hardening treatment on teeth engagement surfaces, significantly extending service life compared to aftermarket alternatives. Regular drivers report noticeable improvements in drivetrain responsiveness after installing this genuine-specification component.

Heavy construction demands durable solutions, and this output flange delivers exceptional performance in mining, freight, and construction applications. The thermal-stable alloy material maintains structural integrity across operating temperatures from -40¡ãC to 150¡ãC, with the tooth geometry preventing oil leakage at high-pressure points. Independent durability testing shows the WG2210100035 withstands over 100,000 fatigue cycles without deformation, making it a cost-effective solution for fleet maintenance programs.

Transport companies recognize significant operational advantages using authentic WG2210100035 flanges. Improved power transmission efficiency translates directly into measurable fuel savings during highway operations, while the precision manufacturing reduces wear on connected components like driveshafts and differentials. Maintenance teams especially appreciate how the clear tooth markings simplify orientation during installation, preventing rotational imbalance that could cause premature bearing failures in transmissions.

Material science advancements contribute to this flange’s exceptional reliability. The billet forging process produces a grain structure aligned with stress directions throughout the component, while specialized coating protects against corrosion in wet operating environments. This attention to material properties ensures consistent performance whether operating in desert conditions or humid coastal regions. Fleet managers in Southeast Asia confirm this product maintains performance integrity even in monsoon conditions where competitors have failed.

Proper installation practices maximize the benefits of the WG2210100035 flange. Technicians should always use factory-recommended torque sequences when mounting to prevent localized stress points. Alignment verification during installation prevents irregular tooth contact that could cause pitting or premature wear. Maintenance logs from numerous fleets indicate proper installation of this component extends transmission service intervals by 15-20%, reducing downtime.

The manufacturing process implements cutting-edge quality control measures that surpass industry standards. Each production batch undergoes coordinate-measuring machine (CMM) verification of all critical dimensions, with laser-etching providing permanent traceability markings. Production technicians specifically evaluate tooth profile accuracy at multiple points, ensuring consistent engagement with mating components throughout the rotational cycle. This commitment to precision means every WG2210100035 provides predictable, long-term performance.

When selecting this output flange for HOWO transmission repair or overhaul, operators gain multiple advantages including vibration reduction and noise minimization. The balanced design eliminates resonance frequencies that could damage transmission bearings, while precise tooth form minimizes gear whine during highway-speed operation. Verified through acoustic testing, these flanges maintain sound levels below 78 decibels at maximum rated operating speeds. After installation, drivers consistently report quieter cabin environments during long-haul operations.

Environmental sustainability considerations are built into the WG2210100035 manufacturing process. The recycling rate of production materials exceeds 92%, with minimal machining waste, while the energy-efficient heat treatment reduces overall carbon footprint. Extended product life means fewer replacements are needed, substantially lowering waste streams from maintenance facilities. These ecological benefits complement the economic advantages already offered to fleet operators.

Supply chain reliability makes WG2210100035 a trusted choice for transmission shops globally. Regional distribution centers maintain strategic inventories, enabling 72-hour delivery to most locations. All shipments include protective packaging specifically designed to prevent shipping damage to precision tooth surfaces. This logistical efficiency has made this flange the preferred choice for emergency transmission repairs in critical freight operations.

Drivetrain specialists emphasize the importance of selecting output flanges specifically designated WG2210100035 rather than generic counterparts. The engineering differences include subtle tooth geometry variations that significantly impact load distribution across the transmission system. Using this precisely engineered component avoids costly repairs resulting from accelerated bearing wear caused by improper force distribution. These differences might seem minor but prove critical to long-term transmission health.

Technical support documentation provides comprehensive installation guidance for the WG2210100035 component, including mounting sequence diagrams and torque specifications for various transmission models. This information is verified against OEM technical resources, ensuring compatibility with all authorized transmission fluids. The downloadable reference materials help mechanics avoid common installation errors that could compromise performance.

Operating cost analysis reveals compelling financial justification for selecting the WG2210100035 output flange. Fleet operators report 23% lower transmission-related repair costs over 500,000 kilometers compared to vehicles using aftermarket solutions. Combined with reduced fuel consumption and extended maintenance intervals, the total ownership cost advantage makes this flange an economically intelligent choice for commercial trucking enterprises. The verified savings often exceed 18% per kilometer over a typical transmission lifecycle.