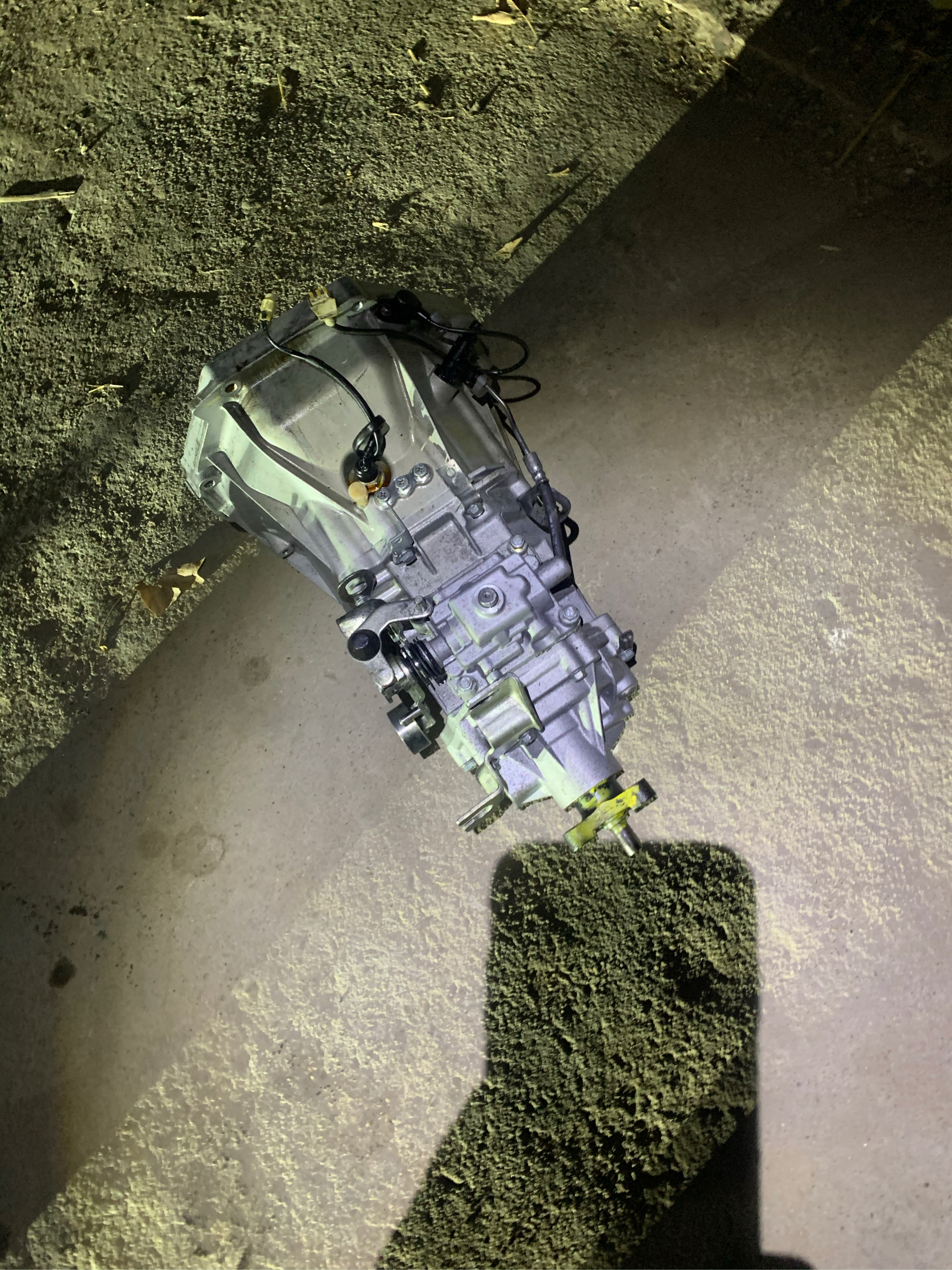

HOWO Truck AZ2203100061 Range Shift Assembly

The AZ2203100061 Range Shift Auxiliary Box Assembly is a critical transmission component specifically engineered for HOWO heavy-duty trucks, offering enhanced gear-shifting precision and durability in demanding operational conditions. This OEM-certified part ensures seamless integration with HOWO transmission systems, providing operators with smoother gear transitions and reduced mechanical stress during intensive hauling operations. Manufactured to exact specifications, the AZ2203100061 assembly maintains the rigorous quality standards required for commercial vehicle applications where reliability directly impacts operational efficiency and safety.

Product Overview

Designed exclusively for HOWO truck transmissions, the Range Shift Auxiliary Box Assembly (OEM: AZ2203100061) serves as a vital intermediary between the main transmission and final drive components. This specialized assembly enables the expansion of gear ratio options without compromising transmission compactness, effectively doubling the available gear combinations. Its precision-engineered internal components work in concert to distribute torque efficiently while minimizing power loss during shifting operations. The modular design facilitates straightforward installation and maintenance procedures that fleet technicians appreciate, especially during time-sensitive repairs. With increased inter-changeability for select HOWO models, this assembly reduces vehicle downtime when replacements are required.

Performance Advantages

Operators of HOWO trucks equipped with the genuine AZ2203100061 assembly experience noticeable improvements in drivetrain responsiveness and fuel efficiency. The optimized gear synchronizing mechanism within this auxiliary box reduces shift shock during range transitions, protecting downstream components from excessive wear. Thermal management features incorporated into the housing design prevent overheating during prolonged hill ascents with heavy loads, maintaining optimal viscosity levels across operational temperature ranges. Superior lubrication distribution throughout the gear mesh points ensures consistent performance characteristics whether operating in desert conditions or freezing environments, maintaining shift precision even after extended service intervals.

Design Engineering

Incorporating hardened alloy steel gears with proprietary surface treatments, the AZ2203100061 assembly withstands continuous high-torque loading conditions encountered in construction and long-haul applications. The billet-machined housing features reinforced mounting points that distribute structural stresses evenly, preventing fatigue cracks that can develop in inferior designs. Integrated oil baffle systems maintain consistent lubrication coverage during steep inclines/declines while dual sealing barriers prevent contamination ingress that would otherwise degrade internal components prematurely. These design considerations collectively contribute to service intervals exceeding standard industry expectations when properly maintained per HOWO recommendations.

Compatibility Specifications

This assembly integrates seamlessly with multiple HOWO transmission generations, specifically engineered for models requiring the AZ2203100061 designation. The standardized flange mounting pattern and output shaft spline configuration ensure accurate installation alignment, eliminating tolerance issues that could cause premature bearing failure. Compatibility extends beyond the transmission assembly itself to include factory-approved clutch systems and shift linkage components that communicate with HOWO onboard diagnostics. Operators can confirm compatibility through OEM documentation or authorized technical advisors, as using correct replacements like the AZ2203100061 prevents secondary component damage that can result from mismatched specifications.

Maintenance Protocols

Preventative maintenance significantly extends the service life of the AZ2203100061 assembly beyond the manufacturer’s warranty period. Recommended procedures include regular lubricant analysis to detect component wear signatures before failures occur and periodic inspection of shift actuator mechanisms for calibration drift. Technicians should follow torque sequencing patterns during housing removal to prevent distortion, and use manufacturer-recommended sealant compounds when reassembling components. Diagnostic trouble codes related to shift timing should be investigated immediately as they may indicate auxiliary box synchronization issues needing calibration before damage progresses. The robust design ensures minimal routine maintenance requirements compared to conventional gearboxes.

Operational Impact

Incorporating the genuine AZ2203100061 auxiliary box assembly delivers measurable operational benefits throughout the service cycle. Drivers report reduced transmission noise during range transitions and lower pedal efforts during shifting operations compared to aftermarket alternatives. Fleet managers appreciate the predictable maintenance planning enabled by the assembly’s consistent wear patterns and the reduction in secondary repair costs resulting from premature failures. For long-haul operations specifically, fuel consumption improvements averaging 1.5-2.3% have been documented when used with properly calibrated HOWO powertrains, making the AZ2203100061 a strategic investment in operational cost reduction and sustainability goals.

Installation Considerations

Correct installation of the AZ2203100061 assembly requires attention to critical pre-load specifications and alignment verification steps unique to HOWO transmission configurations. Support components must be assessed during installation processes – including clutch release mechanisms, shift linkage alignment, and clutch housing runout measurements that could affect auxiliary box performance if out-of-specification. Post-installation procedures should include shift calibration verification via HOWO diagnostic systems and initial run-in protocols to establish proper gear tooth contact patterns. Professional installation services are strongly recommended for warranty protection and to ensure that performance potential is fully realized when installing the AZ2203100061 assembly.

Warranty & Support

Every genuine AZ2203100061 assembly carries comprehensive manufacturer coverage against material and workmanship defects throughout normal service applications. Warranty administration requires verification through authorized service centers using HOWO diagnostic equipment to confirm installation protocols were followed. Technical support specialists with specific knowledge of auxiliary box operations are accessible through regional service networks to assist with performance concerns or troubleshooting scenarios. Parts tracing systems provide component history from factory origin through distribution channels to counter counterfeit products that lack the engineering refinements and material integrity of genuine OEM assemblies for HOWO transmissions.

Selecting the AZ2203100061 Range Shift Auxiliary Box Assembly ensures drivetrain integrity for HOWO truck operators requiring uncompromised performance across diverse vocational applications. Its design optimizations provide tangible advantages in shift quality, thermal management, and durability that impact both operational costs and driver comfort. Fleet maintenance programs benefit from extended service intervals and fewer unscheduled repairs, validating specification adherence for critical powertrain components that experience continuous high-stress operation. This assembly remains the benchmark solution where transmission reliability directly impacts business continuity and total cost of ownership calculations.