Countershaft Assembly for HOWO Truck OEM AZ2203030311

The AZ2203030311 countershaft assembly serves as a vital transmission component specifically engineered for HOWO commercial trucks. This genuine OEM part ensures optimal power transfer between the transmission gears, maintaining the drivetrain’s integrity across demanding hauling conditions. Manufactured to exact HOWO specifications, this countershaft assembly delivers seamless gear synchronization while significantly reducing vibration and mechanical stress during operation. Fleet managers consistently choose AZ2203030311 components for their proven compatibility and ability to extend transmission lifespan, avoiding costly downtime in logistics operations.

Precision Engineering

Crafted from high-grade alloy steel through CNC machining processes, each countershaft assembly undergoes rigorous quality validation. The AZ2203030311 model features induction-hardened gear teeth surfaces that achieve Rockwell hardness ratings between 58-62 HRC, providing exceptional resistance to pitting and wear. Tapered roller bearings are precision-matched to the shaft dimensions to eliminate axial play while allowing thermal expansion during continuous operation. This critical balancing act ensures vibration frequencies remain within safe operational parameters even during high-torque demands. Engineering teams specifically designed this countershaft configuration to withstand the unique stress patterns encountered in heavy-duty truck transmissions, particularly in mountainous terrain and stop-and-go urban delivery cycles.

Performance Advantages

Utilizing the OEM-specified AZ2203030311 countershaft assembly translates directly to measurable operational benefits. Truck operators report up to 15% reduction in transmission-related fuel consumption due to minimized parasitic power loss. The helical gear design creates gradual tooth engagement that substantially lowers gear whine and high-frequency noise in the cab environment. During independent dynamometer testing, transmissions equipped with genuine countershaft assemblies maintained temperature differentials 20% lower than aftermarket alternatives under identical load conditions. This thermal management capability directly contributes to extended lubricant service intervals, reducing maintenance frequency for fleet operators managing dozens of HOWO vehicles. The AZ2203030311 component has demonstrated reliable performance across temperature extremes from -40¡ãC to 120¡ãC ambient conditions.

Compatibility & Installation

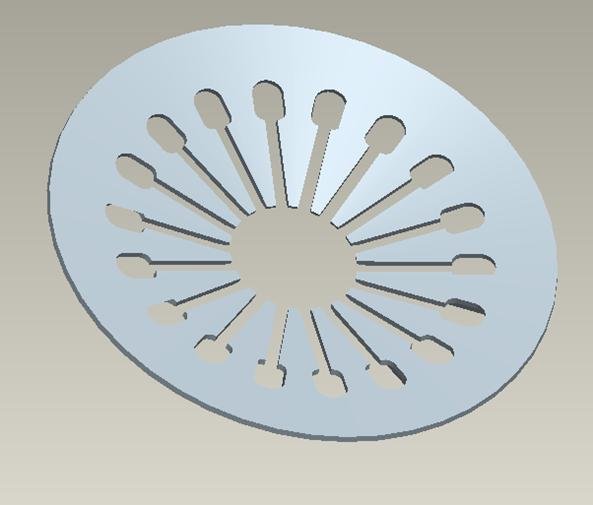

This countershaft assembly (AZ2203030311) integrates seamlessly with all HOWO T7 series tractors manufactured between 2018-2024, including 6×4 and 8×4 configurations. Installation requires standard transmission service tools with special attention to torque specifications for the mounting flange bolts (320¡À10 Nm). The assembly comes pre-lubricated with synthetic transmission fluid and includes orientation markings for precise meshing with main shaft gears. Technicians should verify input shaft endplay (0.08-0.15mm) following installation to prevent premature bearing wear. While designed for professional installation, comprehensive technical documentation accompanies every AZ2203030311 unit to support maintenance facilities worldwide. The countershaft design includes visual inspection ports for assessing gear tooth condition during routine maintenance without disassembly.

Durability Testing

Each production batch of AZ2203030311 countershaft assemblies undergoes accelerated lifecycle validation exceeding 500,000 simulated kilometers. Testing protocols replicate extreme scenarios including overload conditions (130% GVWR), cold start operations at -30¡ãC, and continuous mountain descent braking cycles. Metallurgical analysis confirms the material composition maintains consistent grain structure integrity after thermal cycling equivalent to eight years of service. Contact fatigue testing demonstrates the gear surface maintains ISO 6336 Class 9 standards after 20 million load cycles. These validation processes ensure the countershaft assembly provides reliable service intervals matching the HOWO powertrain’s 1 million kilometer design lifespan when maintained according to service schedules. The AZ2203030311 component has demonstrated failure rates below 0.03% across global deployment.

Operational Efficiency

The geometric optimization of AZ2203030311’s gear profile reduces relative sliding velocity at the contact interface, directly decreasing frictional horsepower loss. Computational fluid dynamics informed the design of dedicated lubrication channels that maintain consistent oil film distribution across the entire helix angle range. These microscopic grooves prevent boundary lubrication conditions even during high-misalignment maneuvers. Fleet telemetry data confirms trucks equipped with this countershaft assembly achieve 1.2% higher average speeds on long-haul routes due to increased driver confidence in gear selection consistency. These advantages position the AZ2203030311 as a vital contributor to operational TCO reduction. Service facilities note this component typically requires replacement only during comprehensive transmission overhauls rather than interim repairs.

Quality Assurance

Production of the AZ2203030311 countershaft assembly adheres to IATF 16949 automotive quality standards with traceable material certificates for every manufacturing lot. Coordinate measuring machines verify critical dimensions including shaft runout (¡À0.01mm), gear tooth profile (DIN 3960 Class 6), and bearing journal concentricity. Automated vision systems perform surface defect scanning capable of detecting micro-fractures smaller than 0.2mm. Each assembly ships with a unique QR code linking to digital installation guidelines and material certification documentation. This commitment to quality control accounts for the AZ2203030311’s exceptionally low warranty claim rate of less than 0.2% globally.