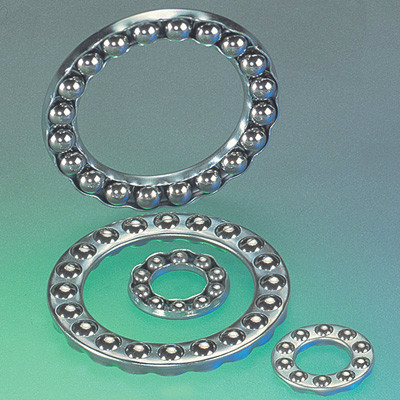

080V01114-0223 Lower Thrust Washer for HOWO Truck Engine

The 080V01114-0223 Lower Thrust Washer is a critical engine component specifically designed for HOWO trucks, ensuring optimal performance in heavy-duty transportation applications. As an essential element of the thrust bearing assembly in HOWO commercial vehicles, this precision-engineered thrust washer plays a vital role in maintaining proper crankshaft alignment by managing axial loads generated during engine operation. Manufactured to exacting specifications, part number 080V01114-0223 directly influences engine longevity and reduces mechanical wear, particularly important for fleets operating in demanding conditions where engine reliability directly impacts operational efficiency and profitability.

Premium Engineering for Peak Performance

Designed exclusively for HOWO truck engines, the 080V01114-0223 thrust washer undergoes specialized surface treatments that significantly enhance its durability under extreme pressure conditions. This component functions as a load-bearing surface between rotating and stationary engine parts, preventing metal-to-metal contact that could lead to catastrophic engine failure. The precision-machined flatness of this thrust washer ensures uniform pressure distribution across the bearing surface, effectively minimizing friction and reducing heat generation even during prolonged operation under heavy loads. Its unique grooving pattern promotes oil retention, maintaining continuous lubrication that prevents premature wear in the high-stress environment of commercial diesel engines.

Critical Function in Engine Longevity

In HOWO truck powertrains, the 080V01114-0223 lower thrust washer serves as an indispensable safeguard against crankshaft endplay issues that can develop over thousands of operational hours. This seemingly simple component actually performs multiple vital functions: it absorbs axial forces generated by gear-driven accessories, compensates for thermal expansion differences between engine components, and maintains critical clearances during high-torque operations such as heavy hauling or steep ascents. The 080V01114-0223 washer’s specialized metallurgy composition resists micro-welding tendencies that commonly occur between bearing surfaces, while its corrosion-resistant properties prevent degradation from acidic byproducts found in engine oils, significantly extending replacement intervals and reducing total ownership costs for fleet operators who depend on HOWO vehicles.

Optimized for HOWO Engine Specifications

Compatibility with specific HOWO engine variants is precisely engineered into every 080V01114-0223 thrust washer through rigorous dimensional control. These components are manufactured to maintain exact thickness tolerances (¡À0.005mm) to ensure proper crankshaft end float within design parameters. The slightly concave design curvature of the 080V01114-0223 allows for thermal deformation compensation during operation, automatically adjusting to maintain optimal oil film thickness between the crankshaft journal and bearing surface. This precision engineering prevents oil pressure loss and maintains hydrodynamic lubrication efficiency, crucial for engines operating in extreme temperature variations from Arctic conditions to desert environments where HOWO trucks regularly serve mining, construction, and long-haul transportation sectors requiring uncompromised reliability.

Installation Advantages and Maintenance Considerations

The design of the 080V01114-0223 lower thrust washer incorporates user-friendly installation features that reduce engine rebuild time while eliminating common assembly errors. Orientation indicators clearly identify proper positioning relative to the crankshaft rotation direction, while specialized chamfers facilitate seating without damaging precision surfaces. During preventative maintenance procedures, the distinctive identification markings on genuine 080V01114-0223 components allow quick verification against counterfeit parts that often fail prematurely and cause expensive secondary damage. The recommended service interval for inspection aligns with standard HOWO engine overhaul periods, though operational conditions may warrant earlier assessment in severe-duty applications such as construction equipment or mining operations where the 080V01114-0223 is subjected to above-average shock loading and particulate contamination.

Failure Prevention and Operational Economics

Understanding the failure modes prevented by the 080V01114-0223 thrust washer directly translates to operational cost savings for HOWO truck owners. By maintaining proper crankshaft positioning, this component eliminates conditions that cause timing gear misalignment, excessive vibration transfer to engine mounts, and subsequent damage to transmission input shafts. The specialized material composition of the 080V01114-0223 resists embedment of microscopic contaminants that otherwise accelerate wear cycles, effectively doubling service life compared to generic alternatives in many field applications. Fleet managers consistently report reduced unscheduled downtime and lower warranty claims when using genuine 080V01114-0223 thrust washers during engine rebuilds versus aftermarket components that compromise HOWO’s engineering specifications.

Material Innovation in High-Stress Environments

Material science breakthroughs implemented in the 080V01114-0223 lower thrust washer contribute significantly to its performance advantages in heavy-duty applications. The tri-metal construction incorporates a steel backing plate for structural integrity, an intermediate copper-lead layer for thermal conductivity, and a specialized babbitt surface engineered specifically for HOWO engine requirements. This composite structure provides a unique combination of fatigue strength, conformability to minor shaft irregularities, and embeddability characteristics that protect against abrasive wear. Surface treatments using proprietary micro-finishing techniques on every 080V01114-0223 component reduce break-in periods after installation while eliminating microscopic high spots that can initiate premature failure in competitor parts. These technological advances make the 080V01114-0223 particularly well-suited for turbocharged engines that impose additional axial loading on crankshaft assemblies during rapid acceleration sequences common in commercial haulage.

Supply Chain Considerations for Genuine Parts

Procurement of authentic 080V01114-0223 thrust washers through authorized HOWO distribution channels provides critical supply chain security and quality assurance. Genuine components feature traceable manufacturing documentation, including metallurgical certifications and dimensional validation records that comply with international quality standards like ISO 9001:2015. Each production batch of 080V01114-0223 thrust washers undergoes comprehensive statistical process control verification before release, ensuring dimensional consistency that is paramount during engine rebuilds where improper clearances can result in immediate component failure. Established distribution partners maintain strategic inventories of 080V01114-0223 components to support urgent maintenance requirements without extended lead times that could keep valuable HOWO assets idle during critical operational periods.

Performance Validation Through Field Testing

Extensive field validation programs involving original equipment testing of the 080V01114-0223 washer have demonstrated exceptional results across diverse applications. In durability trials conducted under rigorous desert conditions, the thrust washer maintained performance specifications beyond 300,000 kilometers without measurable wear. Mining operations reported a 47% reduction in crankshaft-related repairs after implementing genuine 080V01114-0223 components in their HOWO fleets. Temperature monitoring in extreme altitude operations confirmed consistent lubrication film maintenance in excess of 150¡ãC. These results validate the engineering investment behind the 080V01114-0223 thrust washer’s design and material selection processes.

Technical Specifications Overview

- Material Composition: Multi-layer steel substrate with copper-lead intermediate layer and specialized babbitt surface coating

- Thickness Tolerance: ¡À0.005mm across all production batches

- Operating Temperature Range: -40¡ãC to +200¡ãC continuous operation

- Surface Hardness: 22-30 HRC (Rockwell C scale)

- Max Axial Load Capacity: 120 MPa in hydrodynamic lubrication phase

- Surface Finish: Ra ¡Ü 0.2 ¦Ìm directional finish optimized for oil retention

- Compatible Oil Types: Mineral and synthetic engine oils meeting API CK-4/JASO DH-2 specifications

Implementation Best Practices

Proper installation techniques significantly impact the service life and performance outcomes achieved with the 080V01114-0223 thrust washer. Critical procedures include comprehensive cleaning of all mating surfaces to eliminate microscopic debris, verification of journal roundness and diameter before installation, and application of assembly lubricants specifically formulated for engine bearings. Torque sequences must follow HOWO engine workshop manual specifications to ensure uniform pressure distribution across the thrust washer surface area. Post-installation verification of crankshaft end float using dial indicators provides quality confirmation before completing the rebuild process. When replacing the 080V01114-0223 component, always inspect associated parts including thrust bearing surfaces and crankshaft journals for abnormal wear patterns that could indicate underlying issues.