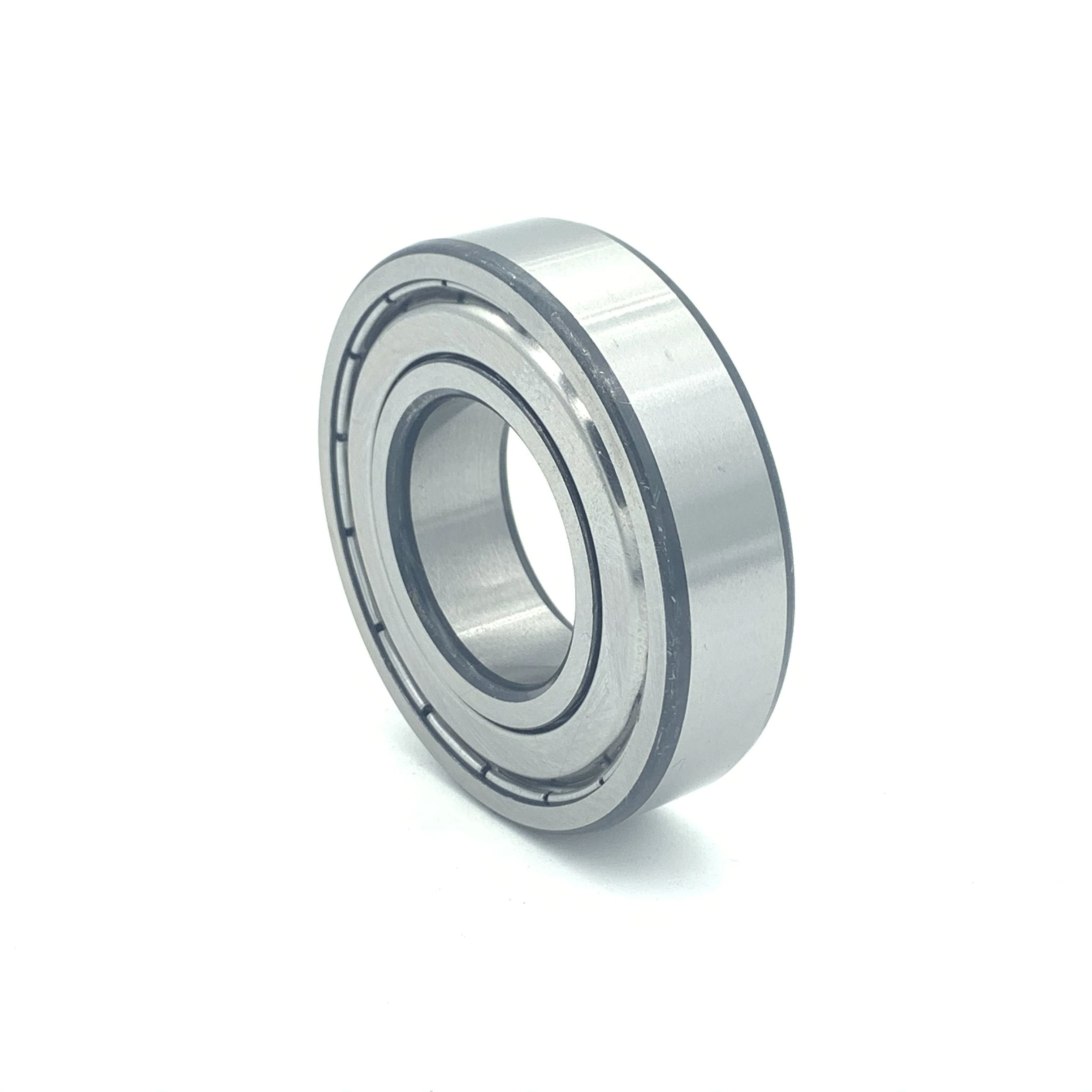

810-62158-2030 Center Bearing for HOWO Truck Cab Parts

Precision-engineered for your heavy-duty needs, the 810-62158-2030 center bearing stands as a crucial component in maintaining the structural integrity of HOWO truck cabins. Designed to withstand immense rotational forces and vibration, this OEM-specified part provides the backbone support needed for smooth vehicle operation. Recognized globally for its reliability in heavy transport applications, HOWO trucks depend on components like the 810-62158-2030 bearing to maintain their reputation for durability in challenging environments.

Optimal Performance Design

The 810-62158-2030 center bearing incorporates advanced materials that resist common failures in heavy-duty applications. Engineered with reinforced steel construction and composite materials specifically chosen for their resilience against deformation, this component directly translates to reduced cabin vibration and smoother driving experiences. For operators managing long hauls across difficult terrains, the importance of a reliable center bearing like the 810-62158-2030 cannot be overstated – it’s the unseen hero that absorbs road irregularities, minimizing fatigue on both the vehicle and driver.

Compatibility and Fitment

Specific to HOWO truck cabin assemblies, this 810-62158-2030 part ensures perfect integration with multiple models across the product line. Unlike generic alternatives that may require modifications for proper installation, the precision dimensions of the 810-62158-2030 component guarantee seamless mounting. This exact fitment eliminates secondary vibrations and potential alignment issues that can plague cabin comfort over time. Owners appreciate the trouble-free installation process and peace of mind knowing that when they use the 810-62158-2030 bearing, they’re maintaining vehicle specifications exactly as designed.

Extended Service Life

Built for longevity, the 810-62158-2030 center bearing features specialized lubricants encased within sealed chambers, preventing premature degradation due to dust exposure. This design significantly extends maintenance intervals compared to conventional bearings. Operators running fleets report fewer breakdowns related to cabin components when using authentic 810-62158-2030 parts. The thermal stability incorporated into this model prevents overheating during prolonged operation, preserving critical internal components. Choosing the genuine 810-62158-2030 part translates to thousands of additional service miles before replacement considerations.

Economic Operation Impact

While premium components may have higher upfront costs, the 810-62158-2030 center bearing demonstrates significant long-term savings. By reducing cabin vibrations, this part contributes to extended cabin component lifetimes throughout the entire structure. Reduced vibrational stress on adjacent parts lowers cumulative repair expenses over a truck’s operational lifespan. Furthermore, the optimized efficiency of the 810-62158-2030 contributes to minor fuel savings by minimizing energy losses due to unnecessary movement. When factoring in reduced maintenance downtime, the 810-62158-2030 bearing clearly presents an economically advantageous solution.

Operational Safety Features

The structural role of the 810-62158-2030 center bearing has significant safety implications. By providing rigid support to the cabin framework, this component enhances vehicle stability during cornering and sudden maneuvers. The bearing’s vibration-dampening properties prevent fatigue fractures in critical junction points, reducing the risk of unexpected cabin movement during operation. Operators particularly appreciate how the 810-62158-2030 contributes to predictable vehicle behavior during challenging driving situations.

Simplified Maintenance Protocols

Maintenance professionals appreciate the service-friendly design incorporated into the 810-62158-2030 center bearing. Accessible lubrication points and standardized removal procedures minimize downtime during service events. Unlike competing products, the 810-62158-2030 model doesn’t require specialized tools for replacement. The modular construction allows partial servicing without complete disassembly, saving valuable workshop time. Clear wear indicators on the 810-62158-2030 enable predictive maintenance planning rather than emergency replacement scenarios.

Environmental Considerations

Manufactured with ecological considerations, the 810-62158-2030 center bearing employs recyclable materials throughout its construction. The extended lifespan of this component directly translates to fewer replacements entering waste streams. Additionally, by maintaining proper drivetrain alignment, the 810-62158-2030 bearing contributes to lower emissions through optimized combustion efficiency. These factors combined create a significant reduction in the environmental footprint associated with heavy transport operations.

Performance in Extreme Conditions

The 810-62158-2030 center bearing consistently delivers reliable performance across temperature extremes that would challenge lesser components. From desert operations to freezing environments, the specialized materials maintain structural integrity and consistent damping properties. Seals remain effective against dust infiltration even during prolonged dry seasons, while cold-weather formulation lubricants prevent thickening that could affect bearing responsiveness. This environmental versatility makes the 810-62158-2030 particularly valuable for international operators traversing varied climate zones.

Acoustic Performance

A critical but often overlooked benefit of the 810-62158-2030 center bearing is its contribution to cabin noise reduction. By efficiently dampening vibrations at their source before they transmit into the cabin structure, this component significantly lowers operational noise levels. The advanced polymer compounds used in the vibration buffer rings absorb sound energy effectively. For drivers spending extended hours in the cabin, the difference between using a standard bearing and the 810-62158-2030 can mean markedly reduced fatigue from continuous ambient noise.

Engineering Evolution

The current 810-62158-2030 center bearing represents decades of incremental improvements in bearing technology. Lessons learned from material failures in previous generations directly informed the composite formulations used today. Computational modeling perfected the load distribution across the entire contact surface. Modern manufacturing tolerances ensure every 810-62158-2030 bearing meets exact specifications. This constant evolution guarantees that operators receive the benefits of cutting-edge research in bearing performance and longevity with each purchase.

Commercial Vehicle Integration

Specifically designed for commercial transport applications, the 810-62158-2030 center bearing addresses challenges unique to heavy trucks that passenger vehicle components never encounter. The extreme torque loads generated under heavy hauling conditions are accommodated within the reinforced housing. Torsional flexing during trailer connection and disconnection is anticipated in the component design. These specialized considerations explain why standard automotive bearings are inadequate for heavy transport applications like HOWO trucks, and why dedicated components like the 810-62158-2030 are essential for operational success.

Global Reliability Standards

Compliance with international quality certifications sets the 810-62158-2030 center bearing apart. Manufacturing occurs under strictly monitored conditions that ensure batch-to-batch consistency. Each production run undergoes statistical sampling against predefined tolerance ranges. Documentation accompanying the 810-62158-2030 bearing provides complete traceability from raw materials to final inspection. These comprehensive standards mean that regardless of where a HOWO truck operates globally, the 810-62158-2030 installed in its cabin meets identical performance expectations.

Operational Value Proposition

The complete value of the 810-62158-2030 center bearing extends beyond the part itself to encompass total operational impact. Reduced maintenance frequency decreases service costs. Extended component lifespans postpone replacement expenditures. Improved fuel efficiency from reduced vibrational losses provides continuous savings. Collectively, these advantages make the 810-62158-2030 a strategic investment rather than a simple spare part purchase. Smart fleet managers recognize that components like the 810-62158-2030 bearing create financial advantages throughout the truck’s service period.

Specialized Applications

Beyond standard haulage, the 810-62158-2030 center bearing excels in specialized transport configurations. For vehicles equipped with auxiliary equipment such as hydraulic lifts or refrigeration units, the additional cabin vibration presents particular challenges. The enhanced damping properties of the 810-62158-2030 maintain cabin integrity where standard bearings would deteriorate rapidly. Similarly, for off-road applications like mining or construction, where irregular terrain creates constant cabin stress, the reinforced design of the 810-62158-2030 provides critical reliability advantages over competitive products.

Precision Manufacturing Techniques

The 810-62158-2030 center bearing benefits from state-of-the-art manufacturing technology unavailable to budget component producers. Computer-controlled grinding creates perfectly concentric mounting surfaces. Heat treatment processes develop exact material hardness throughout the component. Laser measurement verifies dimensional accuracy beyond manual inspection capabilities. These sophisticated techniques create a bearing that delivers identical performance characteristics every time. The manufacturing precision evident in each 810-62158-2030 bearing explains the consistent performance experienced across global operations.