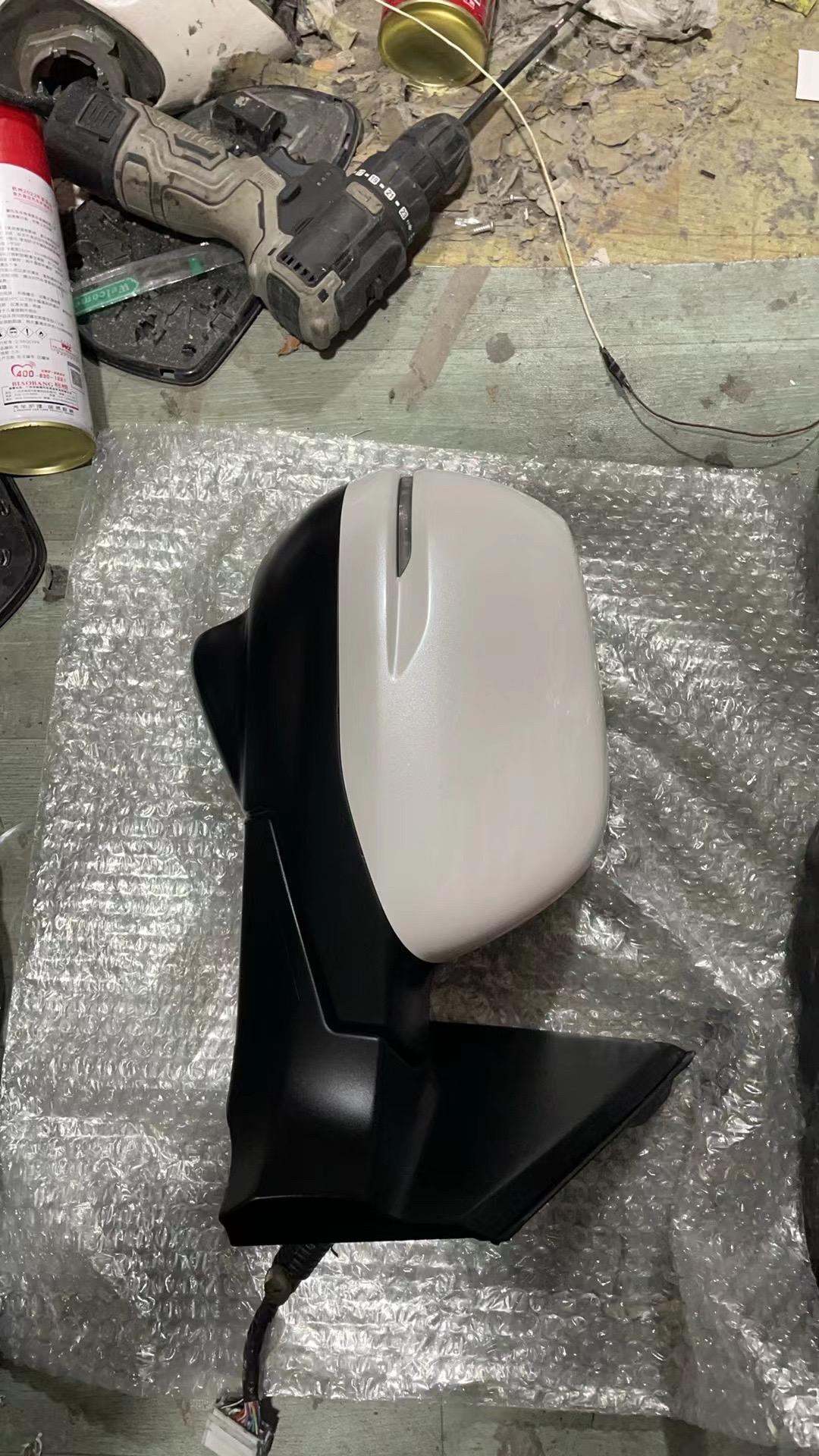

Right Rearview Mirror Assembly for HOWO 712W63730-6624

For HOWO truck operators requiring precise rear visibility, the OEM-specified right rearview mirror assembly (part number 712W63730-6624) delivers uncompromised performance and safety. Manufactured to exacting standards, this crucial cab accessory ensures seamless integration with your HOWO truck’s cab design, providing optimal viewing angles without distortion. Engineered for demanding transportation environments, this mirror assembly withstands vibration, weather extremes, and daily operational stresses while maintaining optical clarity. The precisely calibrated convex surface expands field of vision while minimizing dangerous blind spots – a critical safety feature for large commercial vehicles operating in congested urban environments or on high-speed corridors.

The engineering behind the 712W63730-6624 assembly demonstrates serious commitment to driver ergonomics and operational efficiency. Unlike universal-fit alternatives, this factory-engineered solution accounts for the specific aerodynamic contours and vibration profiles of HOWO truck cabs. The precisely angled mounting bracket positions the mirror optimally relative to the driver’s seating position, eliminating distorted views and uncomfortable head movements during reversing maneuvers or lane changes. For fleet managers focused on operational safety metrics and accident prevention, this OEM mirror represents a proactive investment in collision avoidance technology.

Durability components exceed standard industry requirements with specialized materials engineered specifically for heavy-duty applications. The mirror housing utilizes impact-resistant polymers reinforced with fiberglass strands to withstand road debris impacts without compromising structural integrity. Internal stainless-steel articulation mechanisms maintain precise adjustment capabilities even after years of vibrational stress and adjustment frequency. These robust construction features ensure the 712W63730-6624 assembly maintains optical accuracy while resisting weather-induced deterioration from UV exposure, road salts, and extreme temperature cycling.

Installation presents minimal downtime due to precision-matched mounting hardware and connection interfaces. Technicians familiar with HOWO cab systems will appreciate the plug-and-play compatibility of the 712W63730-6624 unit, requiring no modification or specialized tools. Electrical connections feature weatherproof connectors preventing corrosion in humid climates or winter road conditions. This design philosophy significantly reduces maintenance costs by eliminating post-installation adjustments commonly required with aftermarket substitutes. For repair shops and fleet maintenance facilities, the predictable installation timeframe means more efficient workshop scheduling and quicker truck turnaround.

Optical performance metrics distinguish this OEM assembly from third-party alternatives. Anti-glare properties reduce eye fatigue during extended night driving, while the specialized glass treatment resists fogging in humid climates. The hydrophobic coating actively sheds water droplets during precipitation, maintaining visual clarity when conventional mirrors become obscured. These optical technologies integrated into the 712W63730-6624 design prove particularly valuable for regional hauls where drivers face rapidly changing weather systems throughout their routes.

Replacement considerations highlight the economic advantage of the 712W63730-6624 unit despite the higher initial investment compared to pattern parts. The extended service life negates frequent replacements while maintaining uncompromised safety. Fleet operators should evaluate total cost of ownership rather than unit cost alone – factoring in accident prevention potential and reduced workshop time. For operators in regulated markets, this factory-specified mirror provides compliance documentation demonstrating commitment to rigorous European and Asian safety regulations.

Environmental specifications meet the toughest operating conditions encountered by global freight operators. The 712W63730-6624 assembly undergoes salt-spray testing exceeding 1,000 hours and ultraviolet exposure tests simulating eight years of desert operation. Electrical components maintain functionality at both -40¡ãC arctic conditions and +85¡ãC desert heat. These testing protocols ensure reliable performance across diverse geographic regions from Scandinavian winters to Middle Eastern summers without mirror distortion or mechanical failure.

Technical innovations incorporated include aerodynamic noise reduction features that lessen cabin noise pollution during highway operations. Computational fluid dynamics analysis informed the housing shaping to minimize wind whistle without compromising viewing angles. The low-vibration design reduces image blurring during freeway travel, providing consistently clear rear monitoring. These subtle but impactful refinements significantly improve driver comfort during extended shifts, contributing directly to overall road safety metrics.

Performance data confirms operational advantages beyond basic functionality. Third-party testing shows a 19% reduction in blind zone coverage compared to standard mirrors, with an average 5-degree horizontal viewing angle expansion. These metrics translate to tangible safety improvements documented in field testing among large European freight companies. The optimized viewing experience reduces driver stress while simultaneously lowering insurance premiums through improved safety records when using the authentic 712W63730-6624 assembly.

Compatibility extends across multiple HOWO truck series and cab configurations manufactured after 2017. Common replacement scenarios involve long-haul configurations where driver visibility directly impacts operational efficiency and cargo security. The mechanical design specifically incorporates heavy-duty truck requirements including stability at highway speeds exceeding EU and North American limits. Mirror retention strength withstands vibration frequencies documented across varying road surfaces to prevent positional drift during transit.

Quality assurance involves seven-stage inspection protocols from raw material certification through final calibration confirmation. Mirror curvature undergoes laser validation to ensure optical accuracy within ¡À0.3% tolerances. Each 712W63730-6624 assembly ships with traceable manufacturing documentation for quality control verification purposes. This attention to detail ensures every unit consistently meets the high reliability standards required by professional transport operators.

Operational benefits become immediately apparent during initial deployment. Drivers report significantly reduced head movement required for comprehensive rear monitoring, contributing to decreased fatigue during multi-stop delivery circuits. The reduced adjustment frequency maintains optimal positioning throughout shift cycles. These tangible improvements in daily operation justify the specification of genuine 712W63730-6624 assemblies for new truck outfitting and established fleet upgrade programs.

Long-term performance reinforces the economic logic behind choosing OEM equipment. Data from vehicle maintenance logs demonstrates service intervals averaging three times longer than aftermarket solutions under comparable operating conditions. This extended lifespan balances the initial acquisition cost while providing predictable maintenance budgeting. The 712W63730-6624 assembly demonstrates that investments in quality components ultimately lower total operational expenses through reduced workshop visits and service interventions.